Sturman Industries’ Dual-Fuel Ammonia Engine

By Stephen H. Crolius on October 21, 2016

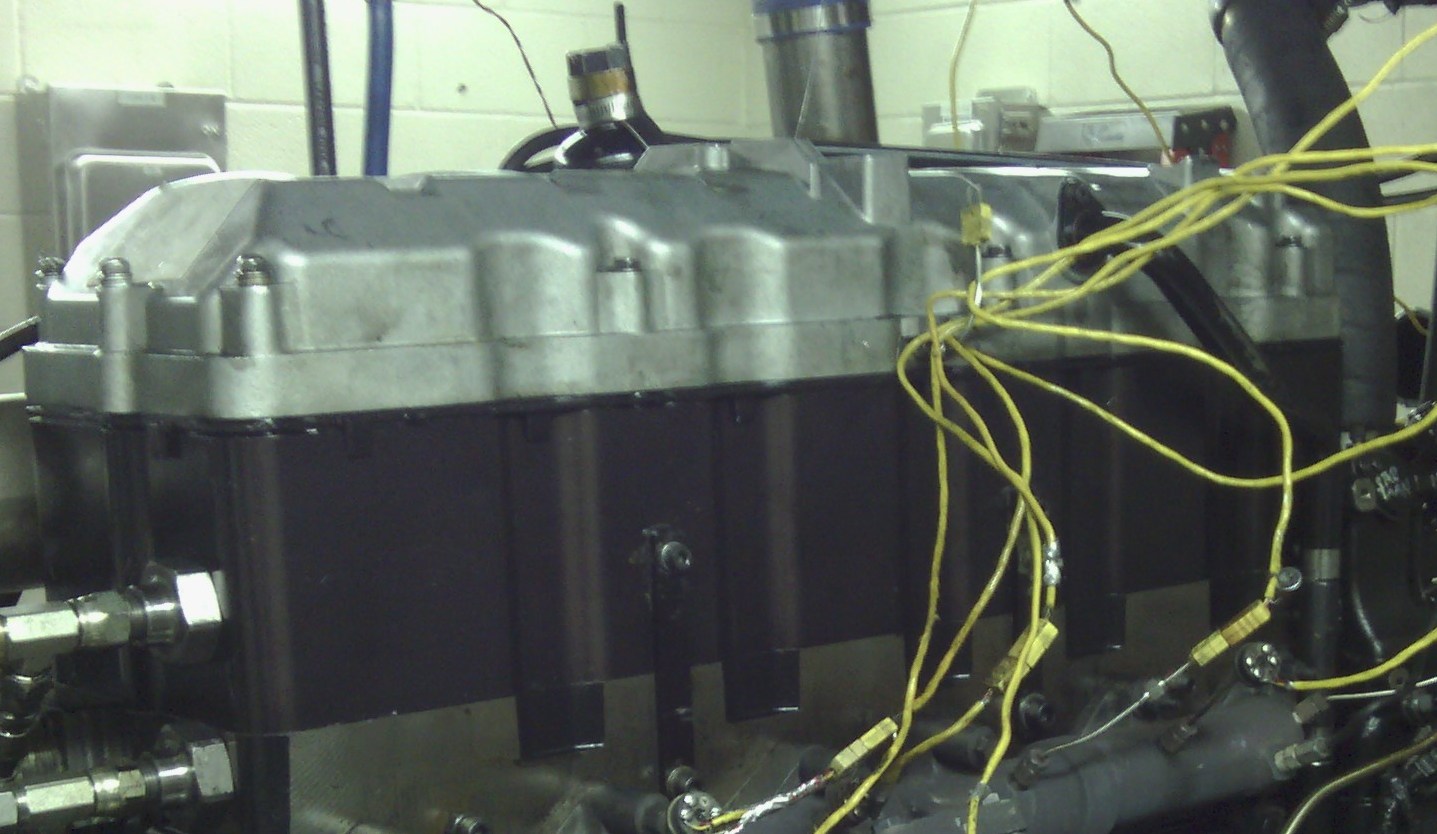

Eddie Sturman, noted inventor and co-founder of Sturman Industries, has been developing ammonia internal-combustion-engine (ICE) technology for several years – “at least six, maybe more.” At the 2016 NH3 Fuel Conference, he provided the most in-depth look so far at the results of Sturman Industries’ R&D program. Specifically, his talk featured a dual-fuel compression ignition engine powered by a combination of diesel fuel and ammonia.

Sturman calls it the ALL-ternative engine, because it is “flexible and intelligent and can operate on many different fuels.”

In an interview this week, Sturman said that his research has confirmed that ammonia has “tremendous potential” as an internal combustion fuel – if the engine’s fuel system is designed properly. “If not, it won’t be able to compete,” he said. In the ALL-ternative engine, diesel fuel is introduced to the combustion chamber via direct injection and ammonia is introduced via fumigation. (A fumigation system injects a gaseous or liquid fuel into the intake air stream of a compression ignited engine.)

The engine, which is built on an International Maxxforce 10 platform, has a compression ratio of 24.5:1. Conventional direct-injection diesel engines typically have compression ratios in the high teens.

The key to the Sturman engine is the company’s proprietary digital valve technology. The valves operate with extreme speed and precision. In the case of the ALL-ternative engine, this enables the execution of ten discrete fuel injection events per combustion cycle.

Sturman explained that although “explosion” is the layman’s term for what occurs when internal combustion fuel is ignited, explosion is not the preferred method of burning the fuel. On the contrary, the ideal is the release of energy over a slightly longer period. This allows the energy to act on the piston throughout its downward travel after passing through top dead center. This approach results in more complete and cleaner combustion and in the production of greater torque.

Sturman pointed out that the ALL-ternative engine’s carbon footprint could be reduced almost to zero by using biodiesel in combination with ammonia. Renewable diesel – an alternative fuel produced via pyrolysis of biomass – could also be used to the same end.

The ALL-ternative engine has not yet been road-tested, but Sturman said that the company is in discussion with a European entity that is interested in the technology.

Introducing Sturman at the NH3 Fuel Conference was Peter Sinsheimer, Director of UCLA’s Sustainable Technology & Policy Program (STTP). Sinsheimer’s presentation described the pilot demonstration project, funded by the California Energy Commission (CEC), to demonstrate the use of NH3 fuel for stationary power generation, using a Sturman internal combustion engine.

The Sturman Industries DICE (Digital Internal Combustion Engine) generator block system is a fully integrated, flexible, and scalable, electrical power generation solution. Utilizing proprietary digital injection and hydraulic valve actuation technology, the power generation system is able to cleanly, efficiently, and cost-effectively convert a wide range of liquid and/or gas fuels into cheap, renewable, sustainable electrical energy.

Piloting a Combined Heat and Power / Distributed Generation System, Powered by Carbon-Free, Renewable-Based Anhydrous Ammonia

Peter Sinsheimer, UCLA, NH3 Fuel Conference, 09/20/2016

UCLA-STTP’s project aims “to evaluate the commercial viability of using renewable-based NH3 for peak power generation and natural gas for base load power in a camless engine genset system to be installed at a distributed generation pilot demonstration facility in the greater Los Angeles region.”