Wärtsilä, Höegh complete floating ammonia cracker concept

By Julian Atchison on April 25, 2025

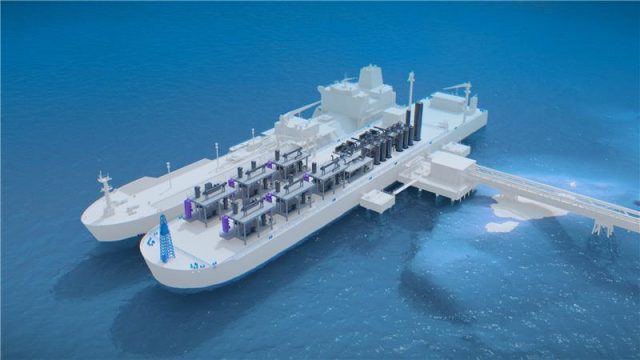

Click to learn more. Höegh Evi and Wärtsilä Gas Solutions have completed their floating ammonia cracker concept, which will feature in a number of ammonia import projects. Source: Höegh Evi.

Höegh Evi and Wärtsilä Gas Solutions have successfully completed development of their floating ammonia cracker concept. Announced in April 2023, the concept has a modular design that allows it to be retrofitted aboard existing hybrid Floating Storage and Regasification Units (FSRUs), and deployed on newbuild hydrogen import terminals. The partners report the concept design can deliver up to 210,000 tons of pipeline-quality hydrogen per year from ammonia imports, and can feature ammonia storage ranging from 10,000m3 to 120,000m3.

The floating ammonia-to-hydrogen cracker developed by Höegh Evi, Wärtsilä and partners is a game-changer for the hydrogen economy and the energy transition in Europe. Our floating terminals and cracking technology can unlock the full potential of global value chains for green hydrogen, providing European industry with a reliable supply of clean energy within this decade.

Erik Nyheim, CEO of Höegh Evi in his organisation’s press release, 24 Apr 2025

This pioneering development of the floating ammonia-to-hydrogen cracker represents a significant leap forward in our quest for sustainable energy solutions. Together with Höegh Evi and our partners, we are not only addressing the challenges of hydrogen storage and transportation but also paving the way for a more resilient and flexible energy infrastructure.

Walter Reggente, Vice President of Wärtsilä Gas Solutions, in his Höegh Evi’s press release, 24 Apr 2025

In June 2024, Höegh LNG announced that it would partner with Deutsche ReGas in the development of “H2-Import-Terminal Lubmin”, a new German import site for ammonia featuring a floating cracker, producing around 30,000 tons of hydrogen per year for injection into the German Hydrogen Core Network. The floating cracker concept will also underpin a new Norway-Germany ammonia supply chain under development by North Ammonia and Höegh Evi, linking North Ammonia’s planned production sites in Norway with demand in mainland Europe.

The project has received approximately €5.9 million in funding from the Norwegian government’s green platform programme. The onboard ammonia cracker was constructed at Sustainable Energy’s Norwegian Catapult Center, and additional partners in the project include the Institute for Energy Technology (IFE), University of South-East Norway, Sustainable Energy and BASF SE.