We do it safely, or not at all: the marine ammonia fuel journey

By Sofia Furstenberg Stott on November 04, 2023

AEA’s latest maritime webinar discussed outcomes from the most comprehensive ammonia safety study to date. Recommendations for Design and Operation of Ammonia-Fuelled Vessels Based on Multi-disciplinary Risk Analysis was prepared by Lloyd’s Register Maritime Decarbonisation Hub and Maersk McKinney Møller Center for Zero Carbon Shipping, and launched this June. The study explores the effectiveness of risk mitigation measures applied to ammonia-fuelled vessels, based on three reference designs: a container ship, a tanker and a bulk carrier. To complement the QRA, the second main section of the report summarizes insights from an analysis of human factors considerations that will be impacted by a transition to ammonia fuel use.

Moderated by AEA’s Maritime Director Sofia Fürstenberg Stott, the conversation included Matt Dunlop, Director of Sustainability & Decarbonisation at V Group and Secondee to MMMZCS, and Samie Parkar, Decarbonisation Risk Specialist at Lloyd’s Register’s Maritime Decarbonisation Hub. Discussion circled around three crucial questions: can ammonia as a marine fuel be used safely, what are the ship safety design principles, and what human factors are involved in adopting the new fuel? You can watch a replay of the discussion here, and download the speaker slides here.

Quantitative Risk Assessment?

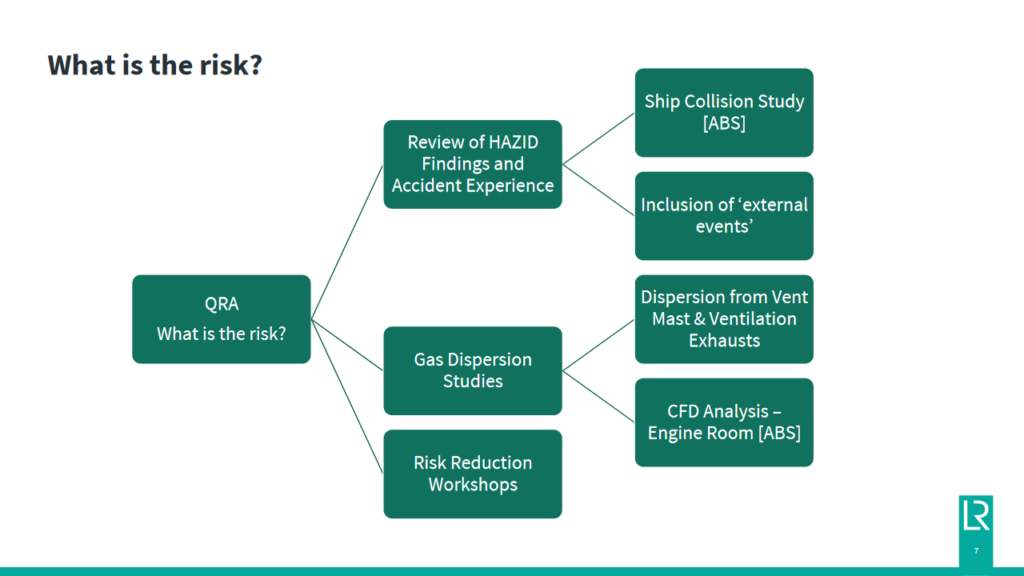

The concept of Quantitative Risk Assessment was briefly explained by Samie Parkar. For the offshore industry, historical data has long been used to determine frequency and severity of risks, developing impact scenarios and mitigation measures through design solutions. This approach is now transferring to novel maritime applications, including ammonia propulsion.

Samie steered us through some details of the analysis itself. Three different vessel types were investigated, each with their own unique risks to crew and design elements. Each vessel had ammonia stored in different conditions. Events such as grounding & vessel collisions were analyzed, including a full collision study and different leak scenarios. Gas dispersion studies & CFD (Computerised Fluid Dynamics) analysis was carried out for interior spaces like engine rooms. A number of Risk Reduction Workshops were carried out with various project stakeholders.

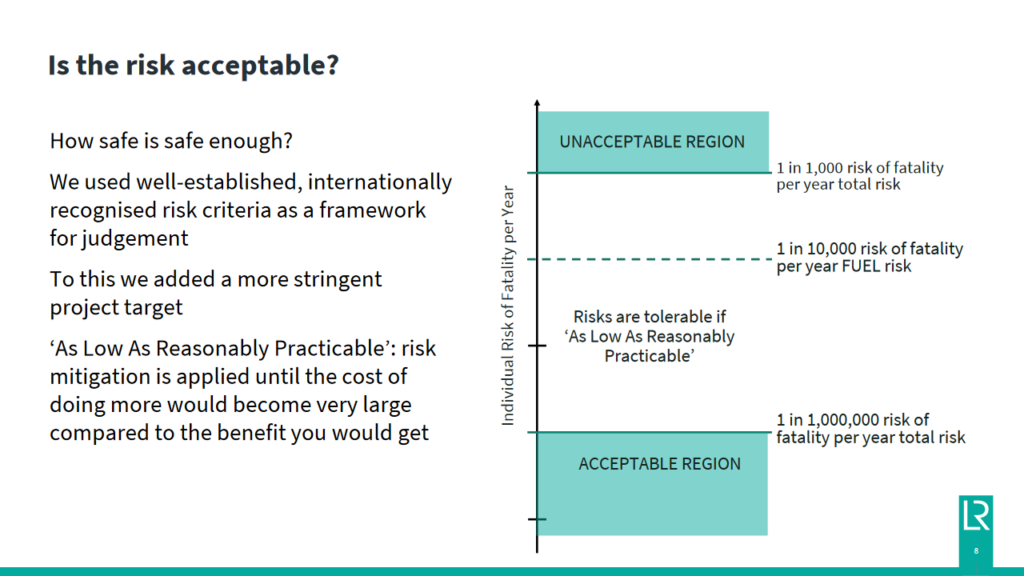

Samie also introduced the audience to the idea of acceptable versus unacceptable risk. Looking at the HSE risk tolerability framework, acceptable risk is nominally set at a 1/1,000,000 chance of individual fatality per year, and unacceptable at 1/1,000. However, a risk can be deemed as tolerable as long as its likelihood is “As Low As Reasonably Practicable”, or ALARP. A risk can be considered ALARP when the cost (sacrifice in terms of money, time or trouble) is grossly disproportionate compared to the risk reduction benefit that could be gained.

Trying to identify exactly where the ALARP line should be set is tricky. Samie noted that in the case of ammonia, tried-and-tested mitigation approaches like partitioning interior spaces, double-walled piping & ventilation solutions are already widespread and their cost can be easily estimated. However, for new tech (especially increased automation), estimating cost is much more difficult. Nonetheless, the ALARP in this analysis was set at a 1/10,000 risk level for the fuel system. The first safeguards that can be applied are design-based. Lower fuel storage temperatures, restricted access time to sensitive spaces, subdivision of leak risks, duct ventilation away from crew, and rapid leak detection can all be included to decrease risk on-board an ammonia-fuelled vessel.

Human factors?

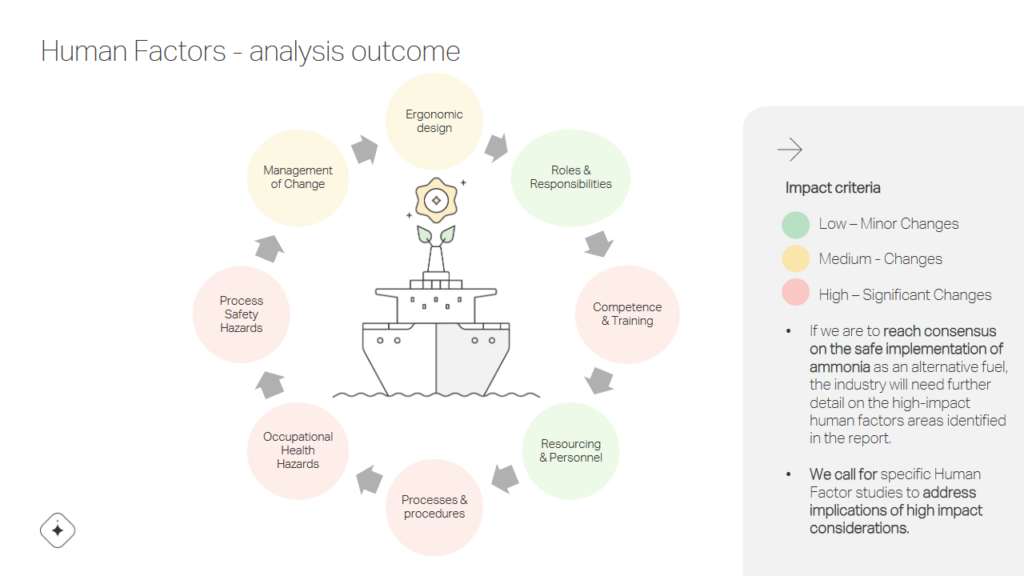

Matt Dunlop then introduced us to the second part of the study – human factors. We rely on design, but ultimately human beings are the ones operating the equipment. By applying human factors early we can incorporate it as a building block, putting performance and wellbeing front-and-center. Matt was eager to emphasize that human factors is not just “home cooking”, but is an approach used in the oil & gas, aviation, and nuclear sectors (amongst others).

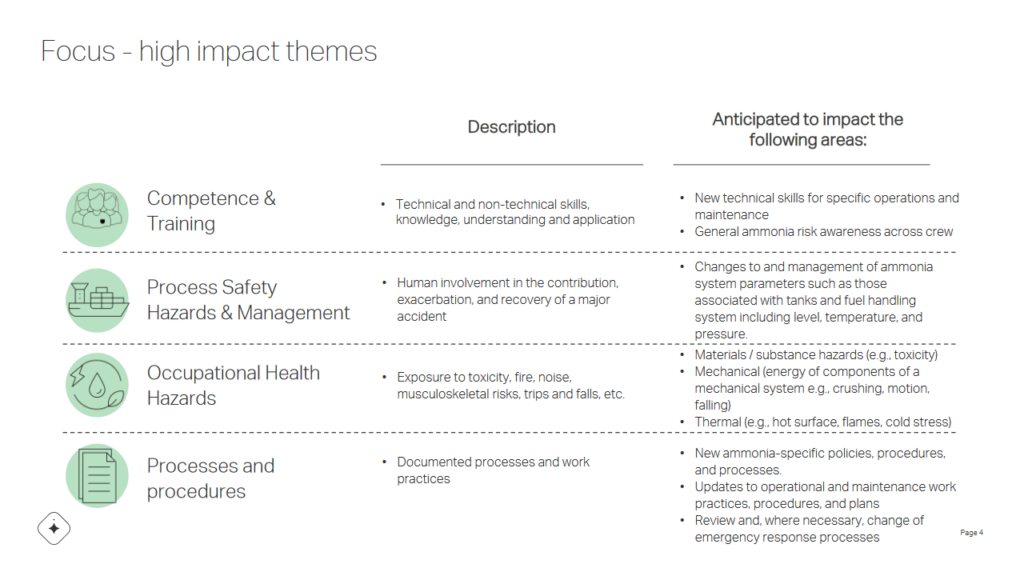

Where there is increasing reliance on human reliability, a human factors analysis is required. Matt noted that we have been carrying ammonia safely as a cargo for many years. So, standards of training for ammonia cargo tanker crews is already high, and we can realistically see a path to training all crews. However, for dry bulk, containers etc. the bar is relatively low for training standards (compared to what they would be for an ammonia-fuelled vessel). So, competence and training is highlighted as one of the critical, “high impact themes” to be addressed, and should not be underestimated in the transition.

Put simply, this is the biggest transformation the industry has ever seen. Matt believes we are on a good path and that we can manage this change, but the industry as a whole has never faced such a challenge as this one. We have to conform to a very tight decarbonisation schedule laid down by the IMO. We need more highly-skilled workers, even though there is a general shortage of seafarers and shore-side workers – not to mention ongoing issues with a lack of gender diversity and associated difficulties with attracting people to the roles!

So, can ammonia fuel be safe? Matt believes yes – if we have suitable tech barriers and admin safeguards. He argues that we need to highlight the need for human factors design criteria for usability and safety on any ammonia-fuelled vessel of the future. Diligent precautions will mean the risks can be managed within safe limits, and (where possible) removing the over reliance on seafarers by using more automation is recommended. In summary: “we do it safely, or not at all”.

Challenges in port

What about the port-side challenges of ammonia fuel? Not wanting to “sugar coat it”, Matt believes this particular challenge won’t be easy. It will require unprecedented industry collaboration, with cohesive info sharing across geographies and stakeholder segments. Regulators and policy makers need to harmonize guidelines – especially critical as different entities are now coming up with an ecosystem of different guidelines. As a great first step, we can work on the guidelines for immediate workers: vessel crew, superintendents etc. Ammonia suppliers, bunker operators, linesmen will all need to be properly educated for when they come onsite.

Ambitious timelines?

An insightful audience member asked if we are perhaps being too optimistic about ammonia engines being ready and available by 2024. Matt suggests this is not overly ambitious – we have the technology, testing and commercialisation pathways all in place. The safety story is not (and should not) be considered a barrier. To demonstrate, he shared his experience visiting the MAN ammonia engine testing center in Copenhagen, not far from the Maersk McKinney Møller Center. Minimal PPE was required, and there was no smell of ammonia during operations. Extensive risk assessments and operational experience had deemed it safe, and steady progress was clearly being made.

This being said – we will absolutely pause for safety if we have to.

Different-sized vessels?

While this study focused on three distinct vessel types, there will absolutely be different outcomes for smaller vessels. Samie remarks that VLCC-sized vessels had beneficial outcomes due to there being more space available – although the risks went up in on-board enclosed spaces, as all the piping and capacity sizes are higher. Now the QRA methodology has been run (a three year process), the analysis can be run on other vessels. Matt comments that – for any vessel – cargo space will have to be reduced for extra fuel, and this may affect smaller vessels more.

Cargo versus fuel

As a cargo, controls already exist for ammonia boil-off and containment. As a fuel, ammonia needs to be heated, pumped and handled in enclosed spaces – a big risk difference. There is already a safe, confident culture around the carrying of ammonia as cargo, and we can build on this. The statistics for carrying ammonia as a cargo are very positive, so let’s transfer this over to ammonia as fuel.

A message for seafarers

As a final word for both speakers, we asked them to give a message to seafarers.

Matt asked seafarers to join us on the ammonia fuel journey. Working together, we can make the industry a greener place. Keeping the focus on safety and wellbeing, there is a real opportunity to attract new seafarers. Positive stories about seafarers will lie at the heart of this transition. Echoing Matt’s message, Samie sees the transition to ammonia fuel as an opportunity to develop new skills at the very leading edge of the industry. Learnings here will apply not just to shipping, but to other sectors as well.