Zero emission aircraft: ammonia for aviation

By Trevor Brown on August 20, 2020

This week, Reaction Engines announced a “ground-breaking study” on ammonia as a fuel for zero-emission aircraft. This will soon be followed by a demonstration project, “integrating the technology into a ground-based test engine.”

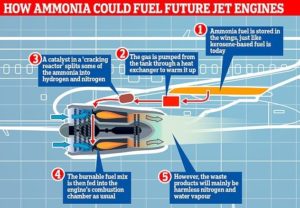

The study combines Reaction Engines’ heat exchanger technology with the ammonia cracking technology being developed by the UK’s Science and Technology Facilities Council (STFC). By partially cracking green ammonia to hydrogen, the resulting ammonia fuel mix “mimics jet fuel,” making it possible to adapt existing engines and aircraft to use zero-emission fuels. “This means a fast transition to a sustainable aviation future is possible at low cost.”

“The combination of Reaction Engines’ transformative heat exchanger technology and the STFC’s innovative catalysts will enable development of a game-changing class of green ammonia-based aviation propulsion systems. Our study showed that an ammonia-fuelled jet engine could be adapted from currently available engines, and ammonia as a fuel doesn’t require a complete re-think of the design of civil aircraft as we know them today.”

James Barth, quoted in Reaction Engines announcement, Reaction Engines, STFC engaged in ground-breaking study on ammonia fuel for a sustainable aviation propulsion system, August 18, 2020

Reaction Engines develops “transformative technology solutions” for space exploration, including its SABRE (Synergetic Air Breathing Rocket Engine) project. Its ammonia fueled aviation project adapts the advanced heat exchangers developed for SABRE, recently ground-tested at Mach-5, for use in commercial aircrafts.

Ammonia fueled flight

We have reported on many ammonia fuel projects here, with perhaps most focus on the maritime and power generation sectors. As the announcement states, “up until now however, it has not been proven to be viable as a fuel for aviation propulsion systems.”

The propulsion system was devised by Reaction Engines and investigated by a team at STFC’s Rutherford Appleton Laboratory … It would have the potential to efficiently crack the ammonia fuel using heat harvested from the jet engine through Reaction Engines’ ground-breaking heat exchangers to provide a zero-carbon fuel blend of ammonia and hydrogen that burns stably just like jet fuel. The density of liquid ammonia allows for conventional aircraft configurations to be used and it may be possible to retrofit into an existing engine, resulting in a zero-carbon jet that could start serving the short haul market well before the 2050 target currently set by the industry.

Reaction Engines announcement, Reaction Engines, STFC engaged in ground-breaking study on ammonia fuel for a sustainable aviation propulsion system, August 18, 2020

While this project represents a first for proving ammonia’s viability as a fuel for commercial aviation, this is not the first ammonia aircraft project. Indeed, the molecule has a proven history as a successful fuel for flight — and, by successful, I mean setting airspeed and altitude records in NASA’s X-15 aircraft.

While the X-15 used a dual-fuel mix of ammonia and liquid oxygen, Reaction Engines proposes to use a single fuel tank and to ‘crack’ some of the ammonia into hydrogen (emitting atmospheric nitrogen), creating a dual-fuel mix of ammonia and hydrogen.

Ammonia-Hydrogen fuel mix

This partial cracking strategy has been a regular theme for ammonia combustion engineers across the years. For example, the University of Minnesota’s tractor uses on-board cracking to produce a 70:30 ratio of ammonia and hydrogen, to replace diesel. And the electric power industry is swiftly growing to appreciate that ammonia’s cold, slow flame and hydrogen’s hot, fast flame can be combined in a gas turbine with combustion properties very similar to methane.

Now, this announcement makes it clear also that a well-controlled ammonia-hydrogen mixture could deliver combustions properties similar to jet fuel.

“We … recently completed the first stage of laboratory tests where we successfully produced the combination of ammonia and hydrogen that mimics jet fuel. Our next step is to scale up to small aviation scale and we are confident that we will achieve this goal.”

Bill David of STFC quoted in Reaction Engines announcement, Reaction Engines, STFC engaged in ground-breaking study on ammonia fuel for a sustainable aviation propulsion system, August 18, 2020

The impact of this is not only that ammonia can be a viable aviation fuel, but also that retrofits will be feasible, significantly reducing the potential cost of decarbonizing the aviation sector.

This announcement follows the Ammonia to Green Hydrogen Project report published earlier this year. This was a BEIS-funded techno-economic analysis of STFC’s ammonia cracking technology, delivered in partnership with Ecuity Consulting, Engie, and Siemens. While the report focused on the market for pure hydrogen generation (ie, PEM fuel cells), the underlying technology is the same. That report, which represented phase one (feasibility) of the BEIS project, will now be followed by phase two (demonstration): “to raise the TRL of a lithium imide based ammonia cracker from 4 to 6/7,” meaning that the technology is ready for deployment.

The environmental impact of ammonia in aviation

Before ammonia could be adopted by the sector, a great deal of analysis and testing must be done to prove the environmental benefits of using ammonia as an aviation fuel. However, there is existing data on the topic.

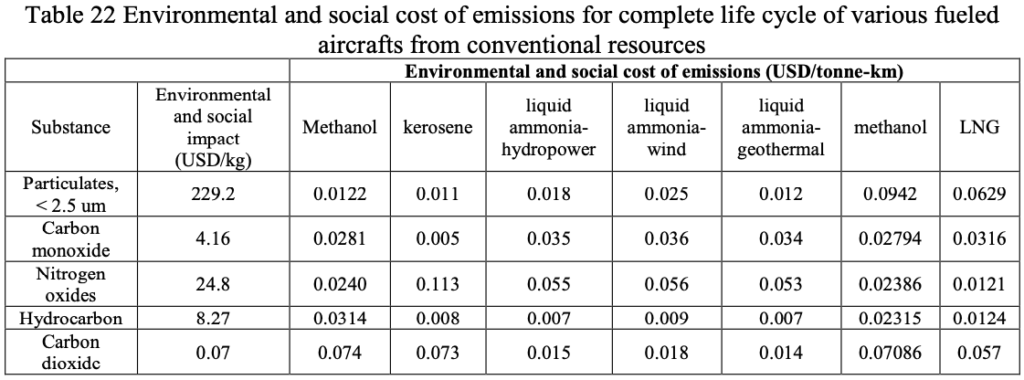

The MITACS-3 joint study by the University of Ontario Institute of Technology and Hydrofuel, Comprehensive Evaluation of NH3 Production and Utilization Options for Clean Energy Applications, takes a “well to wake” approach to determine overall life cycle emissions of conventional and alternative aviation fuels. (“Operation of the aircraft, construction, maintenance and operation of airport, manufacturing of the aircraft, production and utilization of fuel are considered as a complete LCA cycle.”)

The full report is publicly available, but its conclusions for the aviation sector are worth repeating here:

The following conclusion remarks can be derived from this study:

Hydrofuel / University of Ontario Institute of Technology, Comprehensive Evaluation of NH3 Production and Utilization Options for Clean Energy Applications, March 2017

- Alternative aviation fuels including ammonia and LNG are more environmentally friendly options than kerosene.

- Renewable sources based ammonia routes represent the most preferable option in terms of environmental impact.

- Global warming potential of LNG (0.84 kg CO2 per tonne-km) and methanol (1.03 kg CO2 per tonne-km) driven aircrafts are lower than currently used kerosene based jet fuels.

- Renewable resources based ammonia production considerably lowers the environmental impacts corresponding to 0.23 kg CO2 per tonne-km for hydropower route.

- Operation of the aircraft has almost equivalent share (40.7%) with operation and maintenance of the airport (44.6%) in total GHG emissions. Hence, the energy supply of airport facilities are also critical when complete life cycle is evaluated.

- The environmental cost analyses reveal that nitrogen oxides are the highest contributor followed by carbon dioxides.

- The cost of flight is currently lower for kerosene jet fuels however by developing technologies the cost of flight for ammonia can compete with conventional jet fuels.