GenCell launches commercial alkaline fuel cell using cracked ammonia fuel

By Trevor Brown on July 06, 2018

GenCell Energy, the Israeli fuel cell manufacturer, has made two major announcements in the last month. In June, it unveiled its ammonia-fueled alkaline fuel cell system. In July, it announced its first commercial customer.

Its A5 Off-Grid Power Solution is a “nano power plant that operates fully independent of the grid.” The first phase of product trials, using ammonia as a fuel to provide uninterruptible power to cell phone masts, will begin in Kenya by the end of this year, and “product roll-out” is expected in the second half of 2019.

“We are delighted to announce that Adrian Kenya is the first commercial customer in Africa for the GenCell A5 Off-Grid Power Solution following its launch two weeks ago,” comments Rami Reshef, GenCell CEO. “Adrian Kenya’s decision to replace 800 diesel generators with our fuel cell power solution is an affirmation of our business case and our company vision …

The significant OPEX savings of the GenCell A5 solution will make rural connectivity more affordable and accelerate the deployment of communications and other services to the 1.1 billion people who live beyond the grid.”

GenCell Energy press release, Adrian Kenya Selects New GenCell A5 Fuel Cell Solution to Provide Green, Off-Grid Power to 800 Telecom Base Stations, 07/02/2018

The system, which fits into a 20-foot shipping container, includes four primary pieces of machinery. First is GenCell’s patented ammonia cracker, which decomposes ammonia at <700 °C into a mixture of hydrogen and nitrogen. Second is an alkaline fuel cell generator, which uses an electrolyte of potassium hydrochloride (KOH) to generate 4 kW power from the hydrogen fuel. Third and fourth are the “energy bridge for regulating power output” and “heat utilization unit for dissipating excess heat.”

More details about the A5 Off-Grid Power Solution are available via GenCell’s website, which claims that the system offers “Green Energy at Half the Price of Diesel … A single 12-ton tank of ammonia provides enough fuel for a year of 24/7 operation. When installing the GenCell A5 at 1,000 sites or more, you can save up to $250 million or more compared to diesel solutions.”

The GenCell A5 is the world’s first affordable off-grid primary power alternative to diesel generators. It provides cost-effective, ultra-reliable, noise-free and weather-independent power for off-grid and poor-grid telecom base stations at a lower OPEX than diesel generators.

“For the last 20 years, diesel generators have been the dominant primary power source for off-grid or poor-grid base stations,” says Bernard Njoroge, Managing Director, Adrian Group. “But today they are no longer a good fit for modern businesses that seek to minimize OPEX costs or for the environmentally conscious world in which we live.

“GenCell’s ability to create hydrogen from low-cost ammonia to power its fuel cells is a true technological breakthrough with profound impact for the telecom industry. We can now enjoy all the benefits of fuel cells—ultra-reliability, low maintenance, no noise, and zero emissions—with a compelling business case that is too good to ignore. Installing the GenCell A5 Off-Grid Power Solution is good for our business and the environment.”

GenCell Energy press release, Adrian Kenya Selects New GenCell A5 Fuel Cell Solution to Provide Green, Off-Grid Power to 800 Telecom Base Stations, 07/02/2018

The business model: remote power plant for telecommunications

If you’re wondering why this initial market sounds familiar, it is because stationary power generation for base station transceivers in developing countries appears to be the low-hanging fruit for many ammonia fuel cell companies. We have recently written here about other companies working on the same idea, including TowerPower and RenCat. Indeed, I was writing about this exact business model five years ago, in one of my first articles on the subject of ammonia fuel, when I wrote about Project Alkammonia: Ammonia-fed Alkaline Fuel Cells back in April 2013.

Project Alkammonia received major funding from the EU’s Fuel Cells and Hydrogen Joint Undertaking (FCH-JU) in 2013, and it was supposed to conclude in 2016. However, it became severely delayed and, after three extensions, the project finally concluded in June 2018.

The project will integrate three innovative and proven technologies: a highly efficient and low-cost alkaline fuel cell system, a highly efficient and catalytically heated ammonia processing system and a novel solid state ammonia storage system. The integrated system will be rigorously tested, CE certification will be achieved, and the results will be shared with leading telecommunication end-users.

Project ALKAMMONIA will demonstrate significant cost savings compared to the most common current method of remote power generation, i.e. diesel generators as well as to the most common fuel-cell solution in the sector: PEM fuel cells.

FCH-JU website, Project Alkammonia, accessed July 2018

The project has clearly evolved since 2013. While AFC Energy is still the lead partner, new partners have joined, including Amminex from Denmark, the solid-state storage specialist, and Zentrum für BrennstoffzellenTechnik (ZBT, the Center for Fuel Cell Technology) from Germany. ZBT is an “application-oriented, independent development institute,” working with industry partners “with the goal of achieving the market entry of fuel cells.” As such, it does “very close-to-the-market work … for example in the field of manufacturing technology and, in particular, certification.”

At the NH3 Event in Rotterdam, in May 2018, ZBT presented an update on the ammonia cracking technology it had developed for Project Alkammonia, by which ammonia would be broken down into hydrogen (fuel) and nitrogen (emissions).

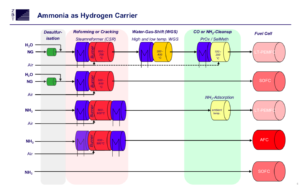

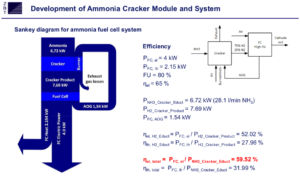

The presentation included this slide comparing fuel cell technologies. The ammonia cracking process is never 100% efficient: there is always residual ammonia in the hydrogen stream. The argument, therefore, for using an alkaline fuel cell with a cracked-ammonia fuel supply is that you don’t need the additional step to purify the hydrogen, because residual ammonia will not impair the alkaline fuel cell performance. With a PEM fuel cell, built on acidic chemistry, the opposite would be true: high-purity hydrogen is required and even very small amounts of residual ammonia would poison the fuel cell.

By avoiding the costs of purification – both the CapEx costs and the energy costs – the alkaline fuel cell achieves a relatively high efficiency.

According to ZBT’s presentation, its 4 kW ammonia-fueled alkaline fuel cell achieved an efficiency of 59.52%.

According to GenCell’s website, its 4 kW ammonia-fueled alkaline fuel cell achieves an efficiency of 52% (fuel cell generator only), consuming a maximum of 2.5 kg/hour ammonia. If combined heat and power (CHP) is considered, the system’s efficiency increases to 87%.

Thankfully, competition is good for technology development, and the market for power plants serving remote mobile communication towers is an area of robust global growth, providing space for all these projects to test their technologies and deploy their commercial products. Now that GenCell Energy, the first-mover, has secured its initial customers, it will have significantly de-risked the business model, making it easier for others to follow.

[Full proceedings from the NH3 Event in Rotterdam are only available online to attendees of the conference. If you weren’t there but would like access to the presentations, please contact the organizers.]