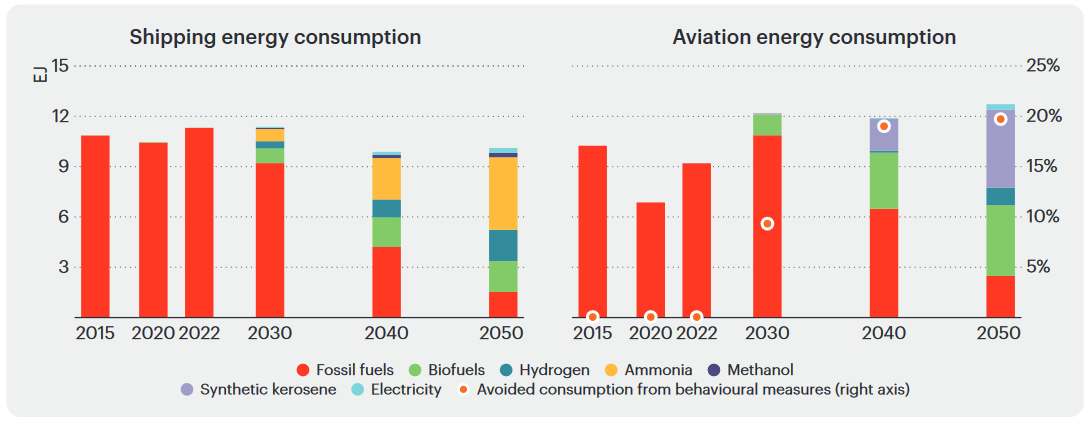

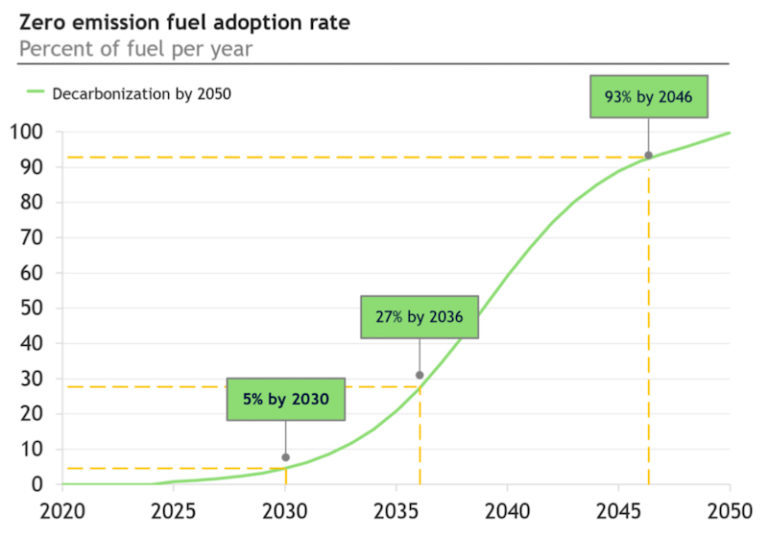

The EU has set a legally binding climate target for 2040, at a 90% GHG emission reduction versus 1990 levels. But, while the 2030 emission target can theoretically be met with limited modifications to existing ammonia production plants in the EU, new technology pathway choices will have to be made well before 2040 to ensure compliance. We explore some of the options, and projects in progress.