BASF’s new 72-stack electrolyser will produce about 8,000 tons per year of renewable hydrogen for use as a feedstock in the company’s production facilities.

Content Related to Siemens Energy

Webinar

FertigHy: reducing dependence on fossil-based fertilizers in Europe

Meet FertigHy, a pan-European consortium that will build, own, and operate low-carbon fertilizer plants across the continent, starting with its first facility in northern France. Explore plans for the 500,000 tons per year facility, which will feature Stamicarbon technology.

Article

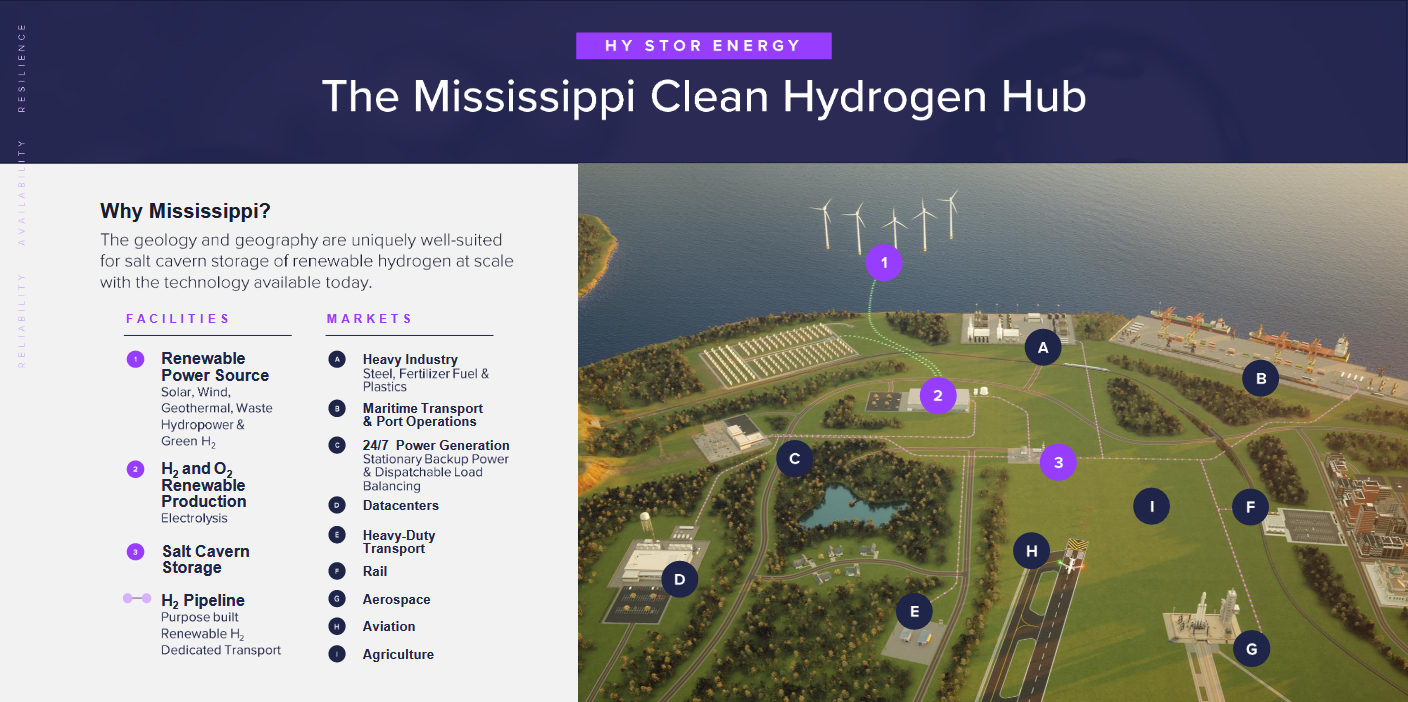

Hy Stor & Nel: electrolyser supply for Mississippi-based renewable hydrogen

Geofrey Njovu May 16, 2024

Nel will supply over 1 GW of alkaline electrolysers for Hy Stor Energy’s hydrogen production and storage hub project in Mississippi, USA. In other electrolyser news, Cepsa and Allied Green Ammonia have picked technology providers for their under-development projects in Spain and Australia.

Article

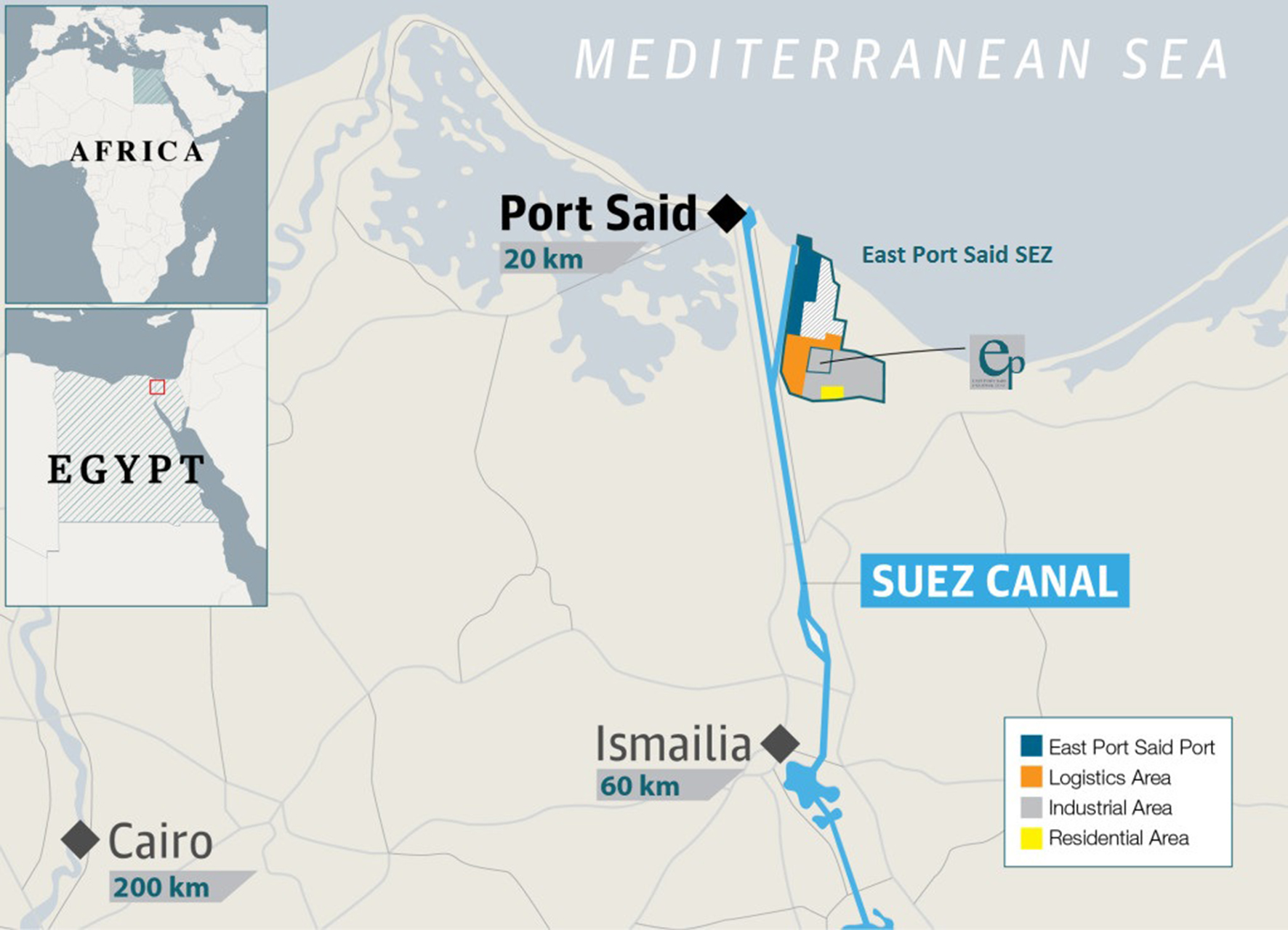

Siemens Energy joins Project Ra

Julian Atchison November 30, 2023

DAI Infrastruktur and Siemens Energy will collaborate on the renewable ammonia project in Egypt, with Siemens to supply electrolysers and equipment for hydrogen production. In June, DAI Infrastruktur announced that Naftomar Shipping & Trading has committed to offtake 400,000 tonnes per year of ammonia for a decade from Project Ra, meaning 85% of production capacity is now covered by offtake agreements.

Article

Certification with blockchain: H2Global makes the case

Oscar Pearce October 04, 2023

In a new policy brief, H2Global sets out the case for the use of blockchain in hydrogen certification. The use of a decentralised, digital, public ledger for key certification data could support the development of radically transparent and secure schemes, though H2Global acknowledges blockchain’s key limitations. To illustrate its potential, H2Global points to the success of two currently operating schemes based on blockchain: “GreenToken” and “Clean Energy Certification as a service” (CEC).

Article

Brooge Energy and Siemens Energy to boost UAE renewable ammonia industry

Geofrey Njovu March 07, 2023

The pair will partner to develop a renewable hydrogen & ammonia project near Abu Dhabi, powered by 650 MW of solar PV in the first phase. The announcement adds to a growing portfolio of electrolysis and CCS-based ammonia projects in the UAE. Also in the Middle East, neighbouring Oman looks to position itself as the ideal “midway” ammonia bunker hub between Rotterdam and Singapore.

Article

Siemens Energy begins work on commercial cracker prototype

Julian Atchison November 18, 2022

Siemens Energy, Fortescue Future Industries and GeoPura are developing a £3.5 million ammonia cracker prototype in Newcastle, UK. The prototype will deliver 200 kg of high-purity, PEM-suitable hydrogen fuel per day, and will be based on Fortescue’s “Metal Membrane Technology” (MMT) purification process. GeoPura will act as offtaker for the prototype facility, with the hydrogen to be used as in its Hydrogen Power Unit fuel cell technology.

Article

Skovgaard renewable ammonia project orders electrolysers from Nel

Julian Atchison July 19, 2022

The consortium developing the Skovgaard ammonia project has ordered an alkaline electrolyser system from Nel, bringing the 10 MW plant a step closer to reality. Skovgaard will be an important test case for hydrogen production directly from renewable energy, with no battery storage or firming to be used.

In other electrolyser news, German-based Sunfire and US-based Electric Hydrogen have received new funding to develop their technologies. Also in Germany, Siemens and Air Liquide will join forces to develop a GW-sized factory in Berlin, with 3 GW of PEM electrolyser units to be manufactured annually by 2025.

Presentation

The role of green ammonia in sector coupling and seasonal electricity storage

Green ammonia (NH3) will have a versatile role in the decarbonisation of large sectors of the global economy. Of these sectors green ammonia will likely have the most competitive potential in decarbonising long-duration energy storage, regional energy and hydrogen transport, shipping propulsion fuel, and replacing existing brown ammonia production for fertiliser and other chemicals. In this presentation, we introduce our modelling on the cross-sector integration of green ammonia into large-scale energy systems, with a case study of India. In the power sector, ammonia may play a role in seasonal storage, system resilience, and electricity import/export. We co-developed the world’s first…

Presentation

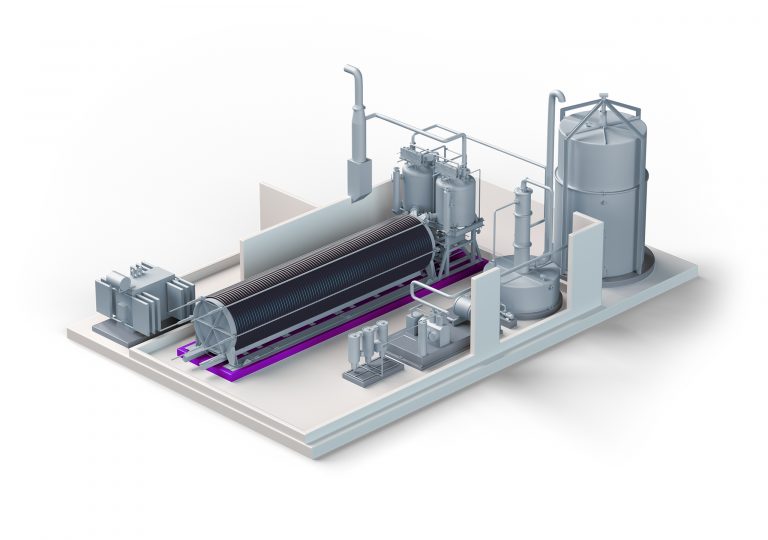

Close-coupling variable green hydrogen production with small scale ammonia production

To deploy green ammonia projects at the scale and speed required to meet decarbonisation targets, we have to revisit conventional methods. There are numerous challenges in coupling renewable energy with ammonia production. This presentation proposes to use ‘Reference Plants’ as building blocks to closely couple green hydrogen and green ammonia plants.

Article

Ammonia Energy Live February - 2021

Julian Atchison March 04, 2021

Last week we presented the first episode in our monthly webinar series: Ammonia Energy Live. Every month we’ll explore the wonderful world of ammonia energy and the role it will play in global decarbonisation - with an Australian twist. To kick things off we wanted to set the scene for 2021 and give you a sense of where the ammonia transition is at - key projects, key milestones and things to be excited about going forward. And, since this is an Australian-focused series, we wanted to explore what’s important about Australia to the ongoing work of the AEA.

Presentation

Platform based Certification Scheme

A robust and internationally recognised certification scheme is critical to facilitate international trade of hydrogen and its carriers (such as ammonia) and other derivatives. There are a number of existing schemes and discussions are under way for further development, often describing the need for a scheme to be transparent, minimal, auditable and future-proof amongst other attributes, all at low cost and with minimum administrative overhead. This presentation proposes to look at a certification scheme from a ‘bottom-up’ perspective by considering possible technical solutions that exist and can be developed to meet the ‘top-down’ expectation.

Article

AEA Australia Announces 2020 Conference

Stephen H. Crolius August 06, 2020

Pandemic or no pandemic, the Australian chapter of the Ammonia Energy Association (AEA Australia) will hold a second edition of its Ammonia = Hydrogen 2.0 Conference this year. The event will be held on a virtual basis on August 27 and 28 from 1:00 to 5:00 p.m. (Australian Eastern Standard Time) each day. The conference tagline is “Building an energy export industry using Green Ammonia.” Its themes this year will be “green ammonia production — jobs for the regions;” “ammonia as maritime bunker fuel;” and “ammonia certification schemes.” The opening address, entitled “Ammonia — is it a fuel, or is it an energy carrier?” will be given by Alan Finkel, Chief Scientist of the Australian Government.

Article

Saudi Arabia to export renewable energy using green ammonia

Trevor Brown July 16, 2020

Last week, Air Products, ACWA Power, and NEOM announced a $5 billion, 4 gigawatt green ammonia plant in Saudi Arabia, to be operational by 2025. Air Products, the exclusive off-taker, intends to distribute the green ammonia globally and crack it back to “carbon-free hydrogen” at the point of use, supplying hydrogen refueling stations. According to Air Products’ presentation on the project, “our focus is fueling hydrogen fuel cell buses and trucks.” This will be one of the first projects to be built in the industrial hub of NEOM, a futuristic “model for sustainable living.” NEOM is a key element in Vision 2030, Crown Prince Mohammed bin Salman’s plan to diversify the Saudi Arabian economy and reduce dependence on oil revenues. In other words, Saudi Arabia is establishing itself as “a global leader in green hydrogen production and green fuels.”

Article

Maersk and partners launch Center for Zero Carbon Shipping

Trevor Brown June 25, 2020

This morning, the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping was announced. Launched with a “start-up donation” of DKK 400 million (USD 60 million) from the A.P. Møller Foundation, this new research institute intends “to develop new fuel types and technologies,” to decarbonize the maritime sector. Behind the Center for Zero Carbon Shipping is a significant industrial consortium with seven founding members (actively seeking additional partners): ABS, A.P. Moller – Maersk, Cargill, MAN Energy Solutions, Mitsubishi Heavy Industries, NYK Lines, and Siemens Energy.

Article

Engie, Siemens, Ecuity, and STFC publish Feasibility of Ammonia-to-Hydrogen

Trevor Brown June 18, 2020

The UK’s Department for Business, Energy and Industrial Strategy (BEIS) recently published the feasibility study for its Ammonia to Green Hydrogen Project. This studies the techno-economic feasibility of importing green ammonia in order to supply large volumes of high-purity low-carbon hydrogen in the UK. The project has been designed and delivered by a heavyweight consortium of ENGIE, Siemens, Ecuity Consulting, and the UK’s STFC. The feasibility study, which is publicly available, represents the conclusion of Phase One of this project. Phase Two is demonstration: “to raise the TRL of a lithium imide based ammonia cracker from 4 to 6/7,” meaning that the technology is ready for deployment.

Article

Cardiff University Launches Ammonia Gas Turbine Project

Stephen H. Crolius April 23, 2020

Last week Agustin Valera-Medina, Associate Professor at Cardiff University in the United Kingdom, told Ammonia Energy that work is underway on a £1.9 million (USD $2.3 million) project that will advance the frontiers of ammonia-gas turbine (AGT) technology. Valera-Medina is serving as the Principal Investigator of the Storage of Ammonia for Energy (SAFE) – AGT Pilot, a four-year effort that hopes to develop “a unique, competitive technology that can be implemented to support the hydrogen transition.”

Article

Los Angeles Commits to Hydrogen-Powered Electricity

Stephen H. Crolius January 30, 2020

Last month the Los Angeles Department of Water Power committed to a hydrogen-powered future. This is one manifestation of forces playing out within California that will transform the state’s energy sector -- and very likely the way policy makers around the world understand the art of the possible.

Article

Gigawatt-scale electrolyzer manufacturing and deployment

Trevor Brown November 14, 2019

ANNUAL REVIEW 2019: Electrolyzers have featured heavily at this year's Ammonia Energy Conference, which ended today. How much can innovation increase efficiency? How far can volume manufacturing drive down capex? How much could process integration with Haber-Bosch deliver improved ammonia production? How realistically can new, sophisticated strategies optimize variable and baseload power inputs? These technical questions are all important, but none defines profitability. While progress is being made on all these fronts of research and development, major industrial projects are still moving forward.

Article

The fertilizer industry is learning to love green ammonia

Trevor Brown October 25, 2019

ANNUAL REVIEW 2019: Green ammonia is no longer a lonely venture for Yara, which used to appear alone among fertilizer producers in its desire to reduce carbon dioxide emissions from ammonia plants. While dozens of green ammonia demonstration projects and prototype technologies have been demonstrated in recent years, this progress was mostly achieved by energy companies and technology start-ups - and Yara. In the last year, however, fertilizer producers on five continents have begun feasibility studies, launched pilot demonstrations, or simply gone ahead and re-engineered their ammonia plants to replace fossil fuel inputs with renewable hydrogen.

Article

Engie, Siemens, STFC, and Ecuity awarded funding for green ammonia-to-hydrogen in UK

Trevor Brown September 06, 2019

Last week, the UK Department for Business, Energy and Industrial Strategy (BEIS) announced a "£390 million government investment to reduce emissions from industry," with a focus on low-carbon hydrogen supply and clean steel production. As part of this investment, a consortium led by Ecuity Consulting that includes Siemens, Engie, and the Science & Technology Facilities Council (STFC), has been awarded £249,000 to perform "valuable research on the role of ammonia in the delivery of low cost bulk hydrogen for use in the UK energy system."

Presentation

Manufacturing ammonia from renewable energy – demonstrator and scale-up potential

The presentation will: Provide an update of the working demonstrator at Rutherford Appleton Laboratories near Oxford where ammonia is produced from renewable energy and used to fuel a Discuss the status of hydrogen production technology and scale-up

Article

The global quest to decarbonize ammonia production

Trevor Brown June 20, 2019

NEWS BRIEF: The industrial process for ammonia production is increasingly being recognized as a target for decarbonization - by researchers, investors, regulators, and the producers themselves. Demonstrating this shift in awareness, Chemical and Engineering News (C&EN), one of the flagship publications of the American Chemical Society (ACS), this week published an in-depth review of global research and development efforts and demonstration plants for sustainable ammonia synthesis. Its review is all-encompassing, from near-term feasible renewable Haber-Bosch plants, to long-term research areas of electrochemistry, photocatalysis, and bioengineering.

Article

AEA Australia conference announced for August 2019: Ammonia = Hydrogen 2.0

Trevor Brown June 13, 2019

ANNOUNCEMENT: The Australian chapter of the Ammonia Energy Association (AEA Australia) has announced details of its inaugural conference, which will take place on August 22 and 23, 2019, and will be held at CSIRO in Clayton, Victoria. Entitled "Ammonia = Hydrogen 2.0," the conference will focus on the role of ammonia within the Australian hydrogen economy, specifically "Building an energy export industry using Green Ammonia." In addition to a full program of talks by invited speakers, networking events will include panel discussions, a poster session, and the conference dinner. Registration for the event is now open, with an early booking discount available until July 5.

Article

NH3 Event in Rotterdam, June 6-7

Trevor Brown May 24, 2019

This year's ammonia conference in Rotterdam, the third annual NH3 Event, begins two weeks from today. Since our guest post in March, announcing the initial roster of conference speakers, the organizers have confirmed new speakers, added more sessions, and announced further details. The NH3 Event is a two-day conference, taking place on June 6 & 7, presenting "state of the art solutions and innovations on the subject of Sustainable Ammonia." Although the conference hall is already close to capacity, a few dozen tickets remain available through the NH3 Event website.

Article

EPRI Releases Ammonia Energy Report

Stephen H. Crolius March 07, 2019

Last month the Electric Power Research Institute (EPRI) released Renewable Ammonia Generation, Transport, and Utilization in the Transportation Sector, the organization’s first public treatment of ammonia energy. The report is positioned as a communique from the cutting edge – a “Technology Insights Brief” from EPRI’s “Innovation Scouts” – and, bracingly, manages to be both brief and comprehensive. Within its format, it does an excellent job of conveying the positive case for ammonia energy and the R&D that will allow it to reach its potential.

Article

Ammonia Gas Turbines on European R&D List

Stephen H. Crolius January 11, 2019

ETN Global’s latest R&D Recommendation was released in October 2018. ETN stands for European Turbine Network and its technology of interest is the gas turbine. The 2018 Recommendation is notable because it is the first that includes ammonia on the R&D agenda.

Article

Ammonia Is Taken Up by Wide-Circulation Media

Stephen H. Crolius October 18, 2018

In the last 12 months ... If a “meme”, in the definition of British psychology professor Susan Blackmore, “is information copied from person to person, including words, stories, technologies, fashions, and customs,” then clearly there is a meme spectrum that has “esoteric knowledge” at one end and “the common wisdom” at the other. Where does ammonia energy fall on this spectrum? “Esoteric knowledge” it may once have been, but this is no longer the case with the concept’s first incursions into mainstream reporting this year.

Article

Siemens Gamesa investigating green ammonia pilot plant in Denmark

Trevor Brown September 06, 2018

Another week, another green ammonia pilot plant. Siemens Gamesa, the world's largest wind turbine manufacturer (by installed capacity), has announced a partnership with local climate innovation fund Energifonden Skive to investigate the production of ammonia from wind power at an eco-industrial hub in Denmark's "Green Tech Valley." The announcement describes "an agreement to jointly explore eco-friendly ammonia production as a way to store surplus electricity from wind turbines. The goal: a pilot plant at GreenLab Skive."

Article

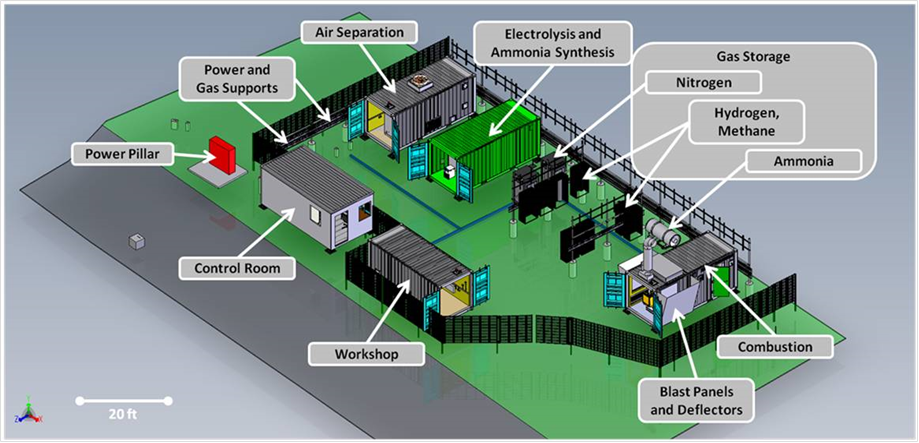

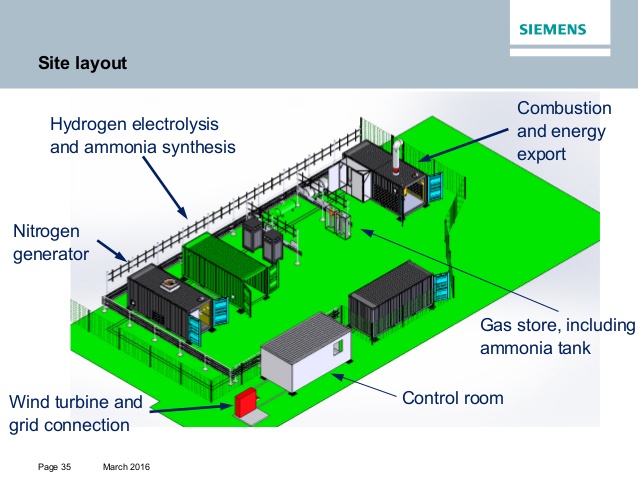

Green ammonia demonstration plants now operational, in Oxford and Fukushima

Trevor Brown June 29, 2018

Two new pilot projects for producing "green ammonia" from renewable electricity are now up and running and successfully producing ammonia. In April 2018, the Ammonia Manufacturing Pilot Plant for Renewable Energy started up at the Fukushima Renewable Energy Institute - AIST (FREA) in Japan. Earlier this week, Siemens launched operations at its Green Ammonia Demonstrator, at the Rutherford Appleton Laboratory outside Oxford in the UK. The commercial product coming out of these plants is not ammonia, however, it is knowledge. While both the FREA and Siemens plants are of similar scale, with respective ammonia capacities of 20 and 30 kg per day, they have very different objectives. At FREA, the pilot project supports catalyst development with the goal of enabling efficient low-pressure, low-temperature ammonia synthesis. At Siemens, the pilot will provide insights into the business case for ammonia as a market-flexible energy storage vector.

Article

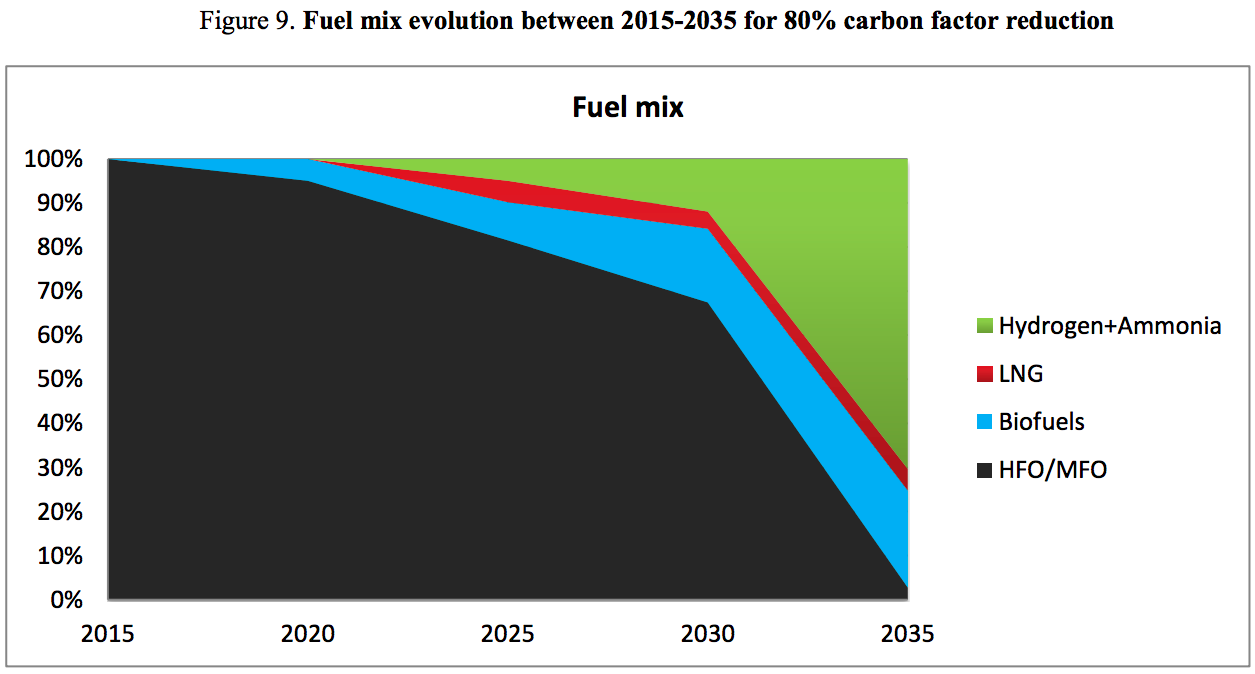

What drives new investments in low-carbon ammonia production? One million tons per day demand

Trevor Brown April 20, 2018

Last week, the International Maritime Organization (IMO) formally adopted its Initial GHG Strategy. This means that the shipping industry has committed to "reduce the total annual GHG emissions by at least 50% by 2050," and completely "phase them out, as soon as possible in this century." This also means that a global industry is searching for a very large quantity of carbon-free liquid fuel, with a production and distribution infrastructure that can be scaled up within decades. The most viable option is ammonia. How much would be required? Roughly one million tons of ammonia per day.

Article

Ammonia Tagged as Storage Medium for Wind Energy

Stephen H. Crolius March 22, 2018

Henrik Stiesdal is a distinguished figure in the field of wind energy. As such, he has had ample occasion to contemplate the field’s challenges and opportunities. Recently he concluded that ammonia may become an important part of wind energy’s future.

Article

Renewable ammonia demonstration plant announced in South Australia

Trevor Brown February 16, 2018

This week, the government of South Australia announced a "globally-significant demonstrator project," to be built by the hydrogen infrastructure company Hydrogen Utility (H2U). The renewable hydrogen power plant will cost AUD$117.5 million ($95 million USD), and will be built by ThyssenKrupp Industrial Solutions with construction beginning in 2019. The plant will comprise a 15 MW electrolyzer system, to produce the hydrogen, and two technologies for converting the hydrogen back into electricity: a 10MW gas turbine and 5MW fuel cell. The plant will also include a small but significant ammonia plant, making it "among the first ever commercial facilities to produce distributed ammonia from intermittent renewable resources."

Article

Full program announced for the 2018 NH3 Event Europe

Trevor Brown February 08, 2018

The second annual European Conference on Sustainable Ammonia Solutions has announced its full program, spread over two days, May 17 and 18, 2018, at Rotterdam Zoo in the Netherlands. The international cadre of speakers, representing a dozen countries from across Europe as well as the US, Canada, Israel, and Japan, will describe global developments in ammonia energy from the perspectives of industry, academia, and government agencies.

Article

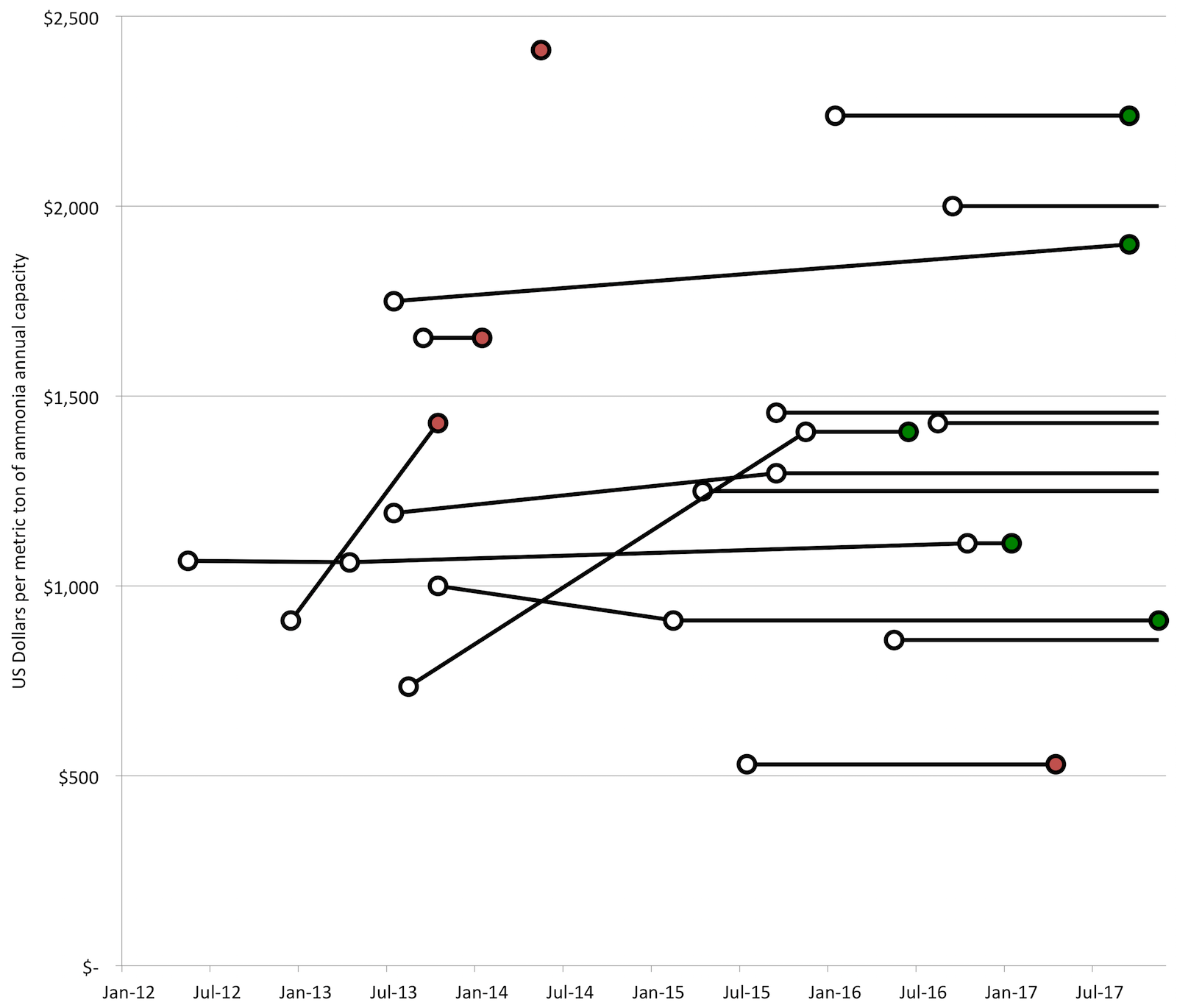

The capital intensity of small-scale ammonia plants

Trevor Brown January 19, 2018

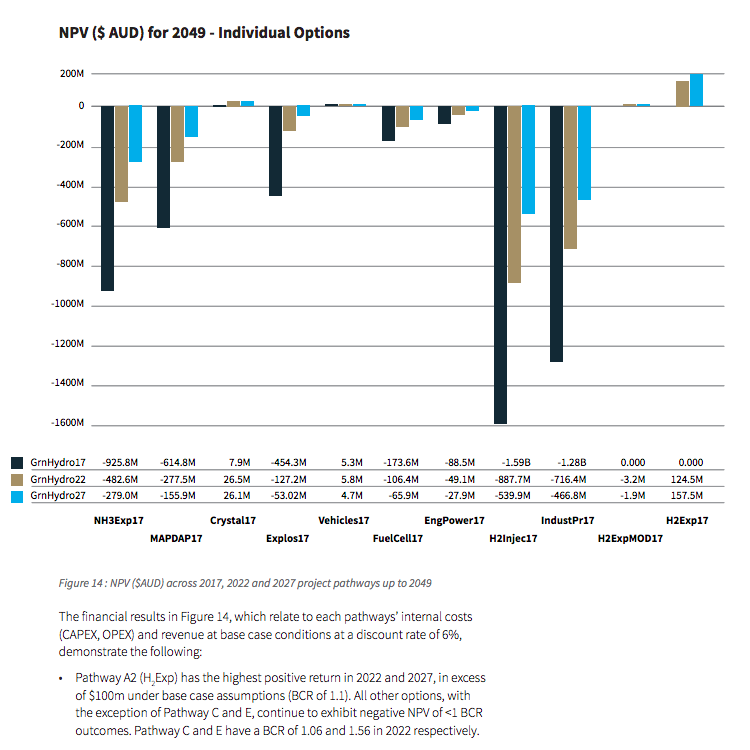

The list of investment drivers for building new ammonia plants in the US over the last few years was short, beginning and ending with cheap natural gas. Markets change, however, and the investment drivers for the next generation of new ammonia plants might include low cost electrolyzers, low cost renewable power, carbon taxes, and global demand for ammonia as a carbon-free energy vector. For this to make sense, however, ammonia needs to be produced without fossil fuel inputs. This is perfectly possible using Haber-Bosch technology with electrolyzers, but today's wind and solar power plants exist on a smaller scale than could support a standard (very big) Haber-Bosch plant. So, to produce renewable ammonia, small-scale ammonia production is essential. This time series chart shows the capital intensity of today’s ammonia plants. Together, the data illustrate competitive advantages of alternative investment strategies, and demonstrate a shift away from the prior trend toward (and received wisdom of) monolithic mega-plants that rely on a natural gas feedstock.

Article

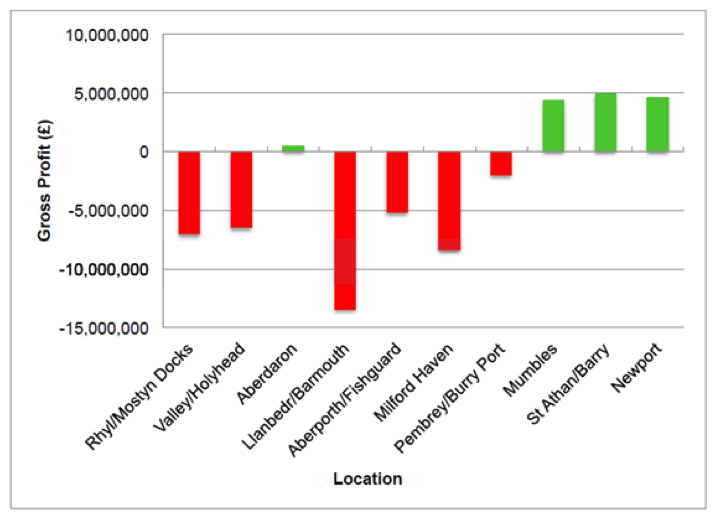

Sustainable Energy for Wales: Tidal and Wind with Ammonia Storage

Agustin Valera-Medina January 11, 2018

As part of the sustainable agenda of the UK, the government, research institutions and various enterprises have looked for options to reduce the carbon footprint of the country while ensuring energy independence for several years. As a response, one of the alternatives has been to introduce the use of marine energy via the implementation of a barrage in the Severn Estuary or the development and implementation of Tidal Lagoons located around the Welsh coast. From these alternatives, the tidal lagoon concept seems to be most feasible. Hybrid tidal and wind energy systems will produce vast amounts of energy during off-peak hours that will require the use of energy storage technologies - the size of each proposed tidal lagoon ranges close to ~1.5 GW. Currently, companies involved in the development of these complexes are thinking of batteries, pumped hydro, and ammonia as the potential candidates to provide storage for these vast amounts of energy.

Article

Green ammonia demonstration plant in The Netherlands

Trevor Brown January 04, 2018

Last month, a heavyweight consortium of local and global companies announced plans to collaborate on a project to design, build, operate, and evaluate a demonstration plant to produce "green ammonia" from water, air, and renewable energy in The Netherlands. This is one practical outcome of last year's Power-to-Ammonia study, which examined the economic and technical feasibility of using tidal power off the island of Goeree-Overflakkee in Zuid-Holland to power a 25 MWe electrolyzer unit, and feed renewable hydrogen to a 20,000 ton per year green ammonia plant. This new demonstration plant phase of the project will still be led by the original developer, Dutch mini-ammonia plant developer Proton Ventures. However, its partners in the venture now include Yara and Siemens, as well as speciality fertilizer producer Van Iperen, and local sustainable agricultural producer, the Van Peperstraten Groep.

Article

Advances in Ammonia-Fired Gas Turbines Open Up Major Use Case

Stephen H. Crolius October 06, 2017

In the last 12 months ... Researchers seeking to fire gas turbines with ammonia made significant strides toward realization of commercial-scale machines in both the U.K. and Japan. This means that electricity generation has become a realistic near-term use-case for ammonia energy.

Article

Yara's Solar Ammonia Plant is a Key Step toward Global Trade in Renewable Energy

Stephen H. Crolius October 05, 2017

In the last 12 months ... Yara's Australian unit announced plans to build a pilot plant to produce ammonia using solar power. This is a key step in Australia's efforts to develop its economy around clean energy exports, and could lead to a new system of global trade in which renewable ammonia is an energy commodity.

Article

Report from the European Conference: Ammonia-Fueled Gas Turbines

Stephen H. Crolius June 22, 2017

The ammonia-fueled gas turbine (A-GT) seems destined to become one of the key technologies in the sustainable energy economy of the future. Siemens AG, for one, features the A-GT in its vision for “Green Ammonia for Energy Storage and Beyond” and the demonstration system that the company is building at the Rutherford Appleton Laboratory in the U.K. Last month Ian Wilkinson, Siemens’ Programme Manager for the demonstration project, spoke about the project’s progress at the 1st European Power to Ammonia® Conference in Rotterdam in The Netherlands. Although he devoted a slide to the A-GT, the detailed perspective came from another presentation at the conference. This one was delivered by Dr. Agustin Valera-Medina, a Senior Lecturer at Cardiff University, one of Siemens’ main green ammonia collaborators.

Article

Australian solar-ammonia exports to Germany

Trevor Brown January 06, 2017

I recently wrote about a vast future market for merchant ammonia: transporting carbon-free energy from Australia's deserts to Japan's electricity grid. Now, however, it is clear that Japan could face international competition for Australia's solar-ammonia resources. Jeff Connolly, CEO of Siemens Pacific, wrote last month about his ambitions for ammonia as an energy export commodity.

Presentation

Ammonia for Green Energy Storage and Beyond

Siemens is participating in an all electric ammonia synthesis and energy storage system demonstration programme at Rutherford Appleton Laboratory, near Oxford. The demonstrator, which will run until December 2017, is supported by Innovate UK. Collaborators include the University of Oxford, Cardiff University and the Science & Technology Facilities Council.

Article

Siemens - Green Ammonia

Stephen H. Crolius September 19, 2016

In April 2016, Siemens AG announced that it will construct a plant at the Rutherford Appleton Laboratory in Oxford to demonstrate the production of ammonia in an electrochemical reactor. The technology is seen as a facilitator of the use of ammonia synthesis as a method for storing renewably generated electricity. It involves lower pressures and temperatures than conventional synthesis with the Haber Bosch process. The project will test two different electrolyte chemistries using its 30 kilowatt electrochemical reactor.