Power to Ammonia: The Stedin – Goeree-Overflakkee case

By Trevor Brown on May 12, 2017

Goeree-Overflakkee, in the southwest corner of The Netherlands, already produces more renewable power than it can consume. But, by 2020, this small island will generate a full 300 MWe of solar and wind, which far “exceeds the electricity demand on the island, rated at maximum 30 MWe peak.”

Stedin, the local grid operator, has the expensive task of integrating these and future renewable resources into its electricity distribution system.

The recent Power-to-Ammonia study included a detailed analysis of Stedin’s business case for producing renewable ammonia as a way to store and transport this electricity – enabling the island to become a net exporter of clean energy.

The investment cost of installing this ammonia production capacity would be partly offset by the avoided costs of expanding the electrical grid. In recent years, Stedin has “invested more than 100 MEUR in increasing the transport and distribution capacity of the electricity grid in order to be able to transport electricity off the island.”

The goal of the project is to convert the surplus of sustainably produced energy from wind or solar energy to ammonia … If wind and solar power increases without demand side management and without electricity storage the investment in grid extensions will be substantial. A rough estimate adds up to around 50 MEUR for Goeree-Overflakkee. The combination of demand side management and local electricity storage can contribute to the reduction of the necessary investments in the grid.

I wrote about the whole Power-to-Ammonia feasibility study last month, but it deserves close attention because it examines three entirely separate business cases for integrating ammonia into a renewable energy economy, centered on three site-specific participants in the study: Nuon at Eemshaven, Stedin at Goeree-Overflakkee, and OCI Nitrogen at Geleen.

Over the next few years, this industrial consortium intends to build pilot projects to develop and demonstrate the necessary technologies. Next week, however, these projects will be an important feature of the Power-to-Ammonia Conference, in Rotterdam on May 18-19.

This article is the second in a series of three that aims to introduce each business case: you can also read about the Nuon – Eemshaven case.

Ammonia – to help the grid and contribute to energy affordability

Stedin describes itself as an “independent partner for private energy facilities and infrastructures,” with a focus on “optimizing energy management in terms of security, safety, cost and sustainability” and managing “sustainable infrastructure such as steam and CO2 networks.” Operating throughout The Netherlands, the company is “a leader in the medium voltage segment (10-25kV).”

“It makes sense to explore new applications that help the grid. Ammonia is such a possibility because it [allows] sustainably produced energy [to] be stored … We deliver innovative projects that contribute to the economy and the sustainability of the energy system. In addition, this technology can contribute to the affordability of energy.”

Guy King, business developer at Stedin, Stedin participeert in consortium duurzame ammoniak (Stedin participates in consortium sustainable ammonia, translation by Google), 04/25/2016

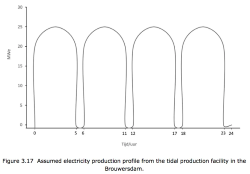

Stedin’s challenge at Goeree-Overflakkee isn’t only to integrate the ongoing surge in distributed renewables, like wind and solar, but also to manage the new generating capacity from a first-of-its-kind tidal power plant.

The [tidal] project not only focusses on the production of renewable electricity, it also serves other purposes. The facility offers the possibility to regulate the water height in the estuary delta, thus increasing safety levels for the inhabitants. It also enhances the environmental situation by bringing back fresh salty water into the presently brackish estuary delta water system. Apart from all these elements, a tidal production facility in an estuary delta system is a new and world class innovative system creating lots of knowledge and economic exportable value.

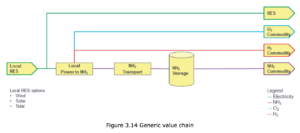

In the Power-to-Ammonia feasibility study, Stedin examines three business cases for converting local renewable electricity to ammonia, from various parts of the island, and transporting it for storage at the nearby industrial port of Rotterdam:

- Tidal power: “The 25 MWe electrolyser is connected to the tidal facility and the aim is to absorb all renewable energy directly. Connection to the grid can be avoided.”

- At the grid substation: “Power cables from various wind and solar production facilities are connected to the grid. Power from the grid is available at this site. A modular setup approach of the NH3 production units will be chosen. The maximum power that can be deployed for production is 50 MWe. The NH3 production facility has a capacity of 40 MWe and is designed to add network flexibility.”

- Wind power / stand-alone. “In this case there will be a more fluctuating supply of power compared with the [grid substation]. Moreover, there is no possibility to use power from the grid.”

Case 1 – Tidal power production facility

Stedin examines the economics of using the full 25 MWe of installed power to produce renewable hydrogen via water electrolysis and feed a 20,000 ton per year (tpy) ammonia plant using conventional Haber-Bosch technology. This equates to a production rate of 2.3 tons per hour of ammonia, consuming 410 kg per hour of hydrogen.

The study assumes that the “specific electric power consumption of the NH3 production unit ranges from 12 to 15 MWhe/ton NH3,” to produce roughly 17,500 tons per year.

The ammonia plant would cost an estimated 42 million euros to build but, because there would be no need for a grid connection, Stedin also counts the avoided cost, “very rough estimation is 15 MEUR,” bringing the net project capex to 27 million euros.

Unfortunately, while tides generate reliable power four times every day (when the tide flows in or out), each time the tide changes direction there is a period of around one hour during which there is no current and, therefore, little-to-no power. This creates a problem for the Haber-Bosch unit, which Stedin assumes must operate constantly at no less than 25% capacity, “because complete shut down and start up put too heavy a load on the installation.” This creates additional cost requirements, for both short-term hydrogen storage and a back-up fuel cell generator.

Case 2: Direct at the grid substation

This business case also assumes constant operation of the Haber-Bosch synthesis loop but at a bigger scale, with a 40 MWe power supply to produce 40,000 tpy ammonia. They give a breakdown of the capex components, at the modular 20 MWe scale:

• 20 MWe PEM electrolyser units: 24 MEUR

• NH3 production unit (including skids and connections): 15 MEUR

• Engineering and unforeseen: 3 MEUR

• This adds up to a total investment (CAPEX) of 42 MEUR (+/- 15%)

• The needed 40 MWe installation means a duplication of installation and is estimated at 78 EUR.

The total installation cost demonstrates some cost savings through efficiencies of scale compared to the tidal power plant, which was half the size and, with an avoided cost of 12 million euros, the net capex comes to 66 million euros.

Because the renewables connected to the substation are intermittent, this case assumes that the ammonia production system will draw power from the grid when required – and this has a significant impact on the carbon footprint:

The part of the NH3 produced with sustainable electricity from the grid will be covered with green certificates which proving that the NH3 is being produced without CO2 emissions. It shall be considered that NH3 produced by the P2A plant consuming grey electricity will result in specific CO2-emissions of 6 ton CO2 per ton NH3 where the conventional SMR based process result in specific emissions of 1.8 ton CO2 per ton NH3. This implies that for every ton NH3 produced from grey electricity at least 2 tons of “green” NH3 must be produced to reach a break-even point on CO2-emissions.

Case 3: Stand alone

The third case is only briefly considered: it is quickly deemed uneconomical because of the hydrogen storage requirements.

In order to avoid a shutdown of the plant H2 storage of sufficient size is needed to produce a certain period on a minimum level of 25% capacity.

The capacity for H2 storage needed to overcome the time periods when there is no electricity production is substantial. This is heavily impacting the business case … Case 3 will therefore not further be analysed.

I note that others are actively pursuing the “stand alone” model, most recently including the International Energy Agency (IEA), about which we’ve written repeatedly, on the subjects of carbon-free ammonia and the hydrogen consensus. The IEA cited projects that could be located either beside baseload (constant) sources of renewable power, like hydro or geothermal, or powered by both solar and wind because the two, combined, have a reduced intermittency.

Conclusions

Stedin is going to continue developing the project, with the support of the local government:

On Goeree-Overflakkee the efforts continue to produce NH3 on a small scale with green energy (wind and sun). The government of Goeree-Overflakkee is interested in the possibilities to use the produced NH3 (or urea) on the island. This contributes to more sustainability and local employment opportunities but will require a premium to be paid for the green character … More research should be done and a pilot for NH3 synthesis has to be built to see if operation on interval basis is possible.

This is encouraging because, unsurprisingly, given the cost of electrolyzers, Stedin concludes that it wouldn’t be profitable to install power-to-ammonia today – although it acknowledges that the economic argument isn’t the only one worth considering.

• For all of the three cases that have been studied there is no positive business case for the production of NH3 from electricity at this moment …

• The case where NH3 is produced directly at the grid substation in Middelharnis has appeared most promising. The other two cases are less interesting due to the fact that the intermittent production of renewable electricity means lower utilisation of the installed assets and the need for larger and costly storage facilities for H2 in order to operate the Haber-Bosch process section at its minimum capacity of 25%.

• An advantage of producing NH3 with wind and solar power for the grid owners will be lower investments in the grid …

• P2A as a new way to convert local renewable electricity into a valuable energy carrier can … be applied at increasing production capacities in the near future. This means that not only the investigated case at Goeree-Overflakkee might seem interesting, also in other areas where substantial grid investments are needed the P2A technology might be interesting and worthwhile to investigate.

Stedin sees ways by which today’s business case can be improved: primarily, the “expected lower cost for electrolyser technology, that will positively influence the business case,” but also “offering specific grid services of the P2A installation,” and “accounting for a rising CO2 penalty on competing existing technologies based on fossil resources.” In addition, two potential value streams were excluded from its analysis: “the valorisation of individual streams as oxygen (O2) and H2 are not taken into account,” and also “the grid balancing services are taken into account, but not given any value.”

Perhaps most importantly, Stedin makes the important additional point that we can’t rely on today’s economics alone to guide our long-term investment decisions:

The business case still appears not attractive from a pure economic point of view. However from a societal point of view, [Case 2] is most promising because investments in the grid are being diverted to support a new sustainable initiative also offering new economic potential for Goeree-Overflakkee.

This call to action also echoes the call from Japan requesting product labeling to enable calculation and appropriate (premium) pricing of the carbon content of ammonia:

Presently, NH3 can only be produced on Goeree-Overflakkee when the higher production costs of this medium can be allocated to its zero emission “green” character. This means that the NH3 can only be put in value chains that allow for a higher NH3 price and award the “green” locally produced character. It now seems interesting to further investigate the potential for this NH3 as a building block for zero-emission fertilizers.

You can download the full Power to Ammonia feasibility study from the ISPT website.

Read the full article at AmmoniaIndustry.com.