Denmark

Safe ammonia bunkering & port operations: digging into detail

We explore the development status and the action being taken to assess the ammonia maritime fuel opportunity at the Port of Roenne on Bornholm Island in the Baltic Sea.

Renewable ammonia: key projects & technologies in the emerging market

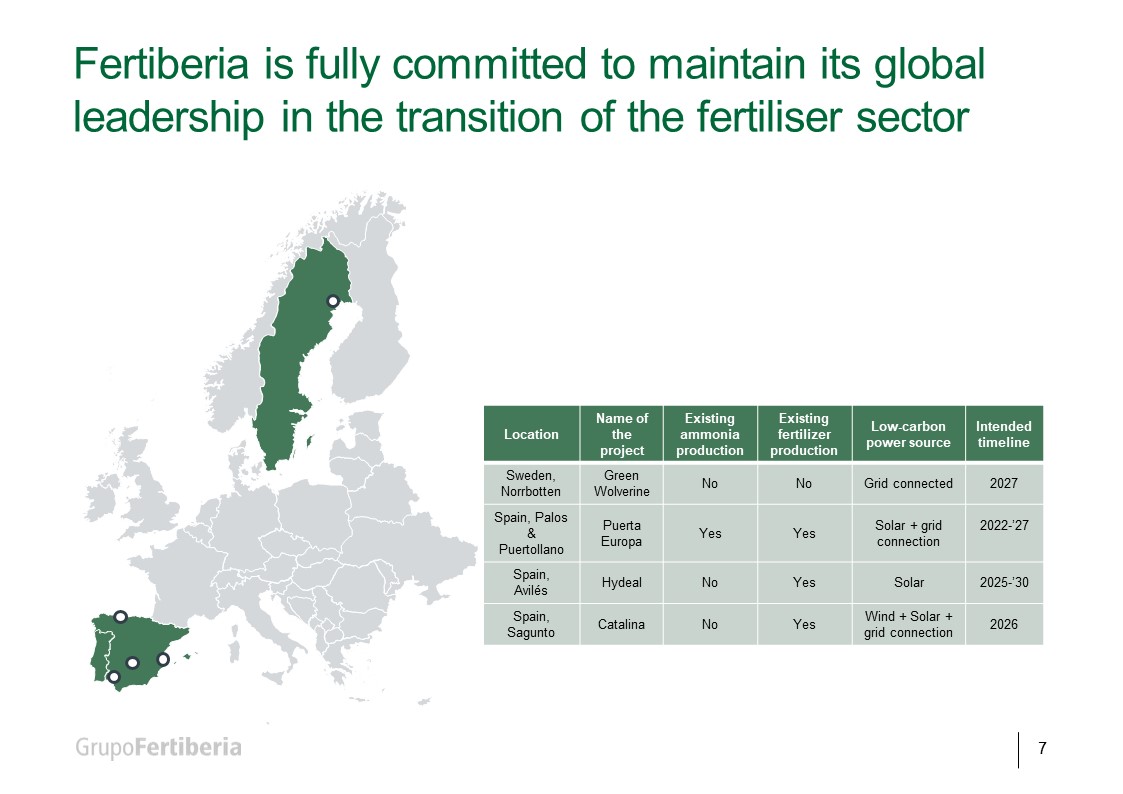

For the latest episode of Ammonia Project Features, we explored the ongoing renewable ammonia project in Puertollano, Spain. Marc van Doorn (Grupo Fertiberia) and Imanol Arrizabalaga Prado (Nel ASA) discussed progress to date and technologies used at the first large-scale, electrolysis-based hydrogen facility in Europe, which is operated by renewable energy developer Iberdrola. We also considered what other pioneering projects are on the horizon, and how can electrolyzer manufacturers like Nel scale-up to meet growing demand?

EverWind Fuels and Svitzer to jointly develop ammonia-powered tugboat

EverWind Fuels and Svitzer have signed an MoU to deploy an ammonia-powered commercial tug in the Canso Strait, adjacent to Point Tupper: the location of EverWind’s under-development hydrogen & ammonia production hub.

A road ahead via lithium-mediated electrochemical nitrogen reduction?

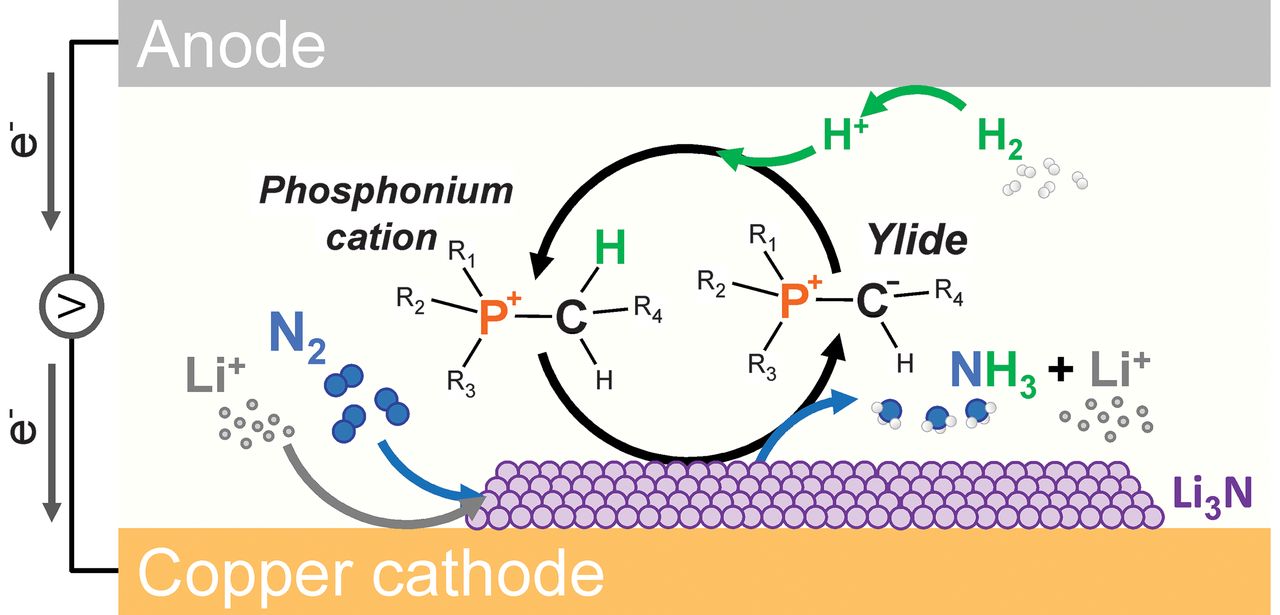

Realisation of electrochemical nitrogen reduction to ammonia has proven to be a herculean scientific challenge. Recently, a focus on Lithium-mediated synthesis has delivered promising results. Last year a team from Monash University in Australia unveiled their phosphonium “proton shuttle” method, and this year have reported nearly 100% Faradaic efficiency for the reaction (with promising reaction rates). Late last year, a team from the Technical University of Demark (DTU) reported that addition of small amounts of oxygen gas drastically increased Faradaic efficiencies and production rates. The results push electrochemical synthesis R&D ever-closer to elusive benchmarks set for commercial realisation.

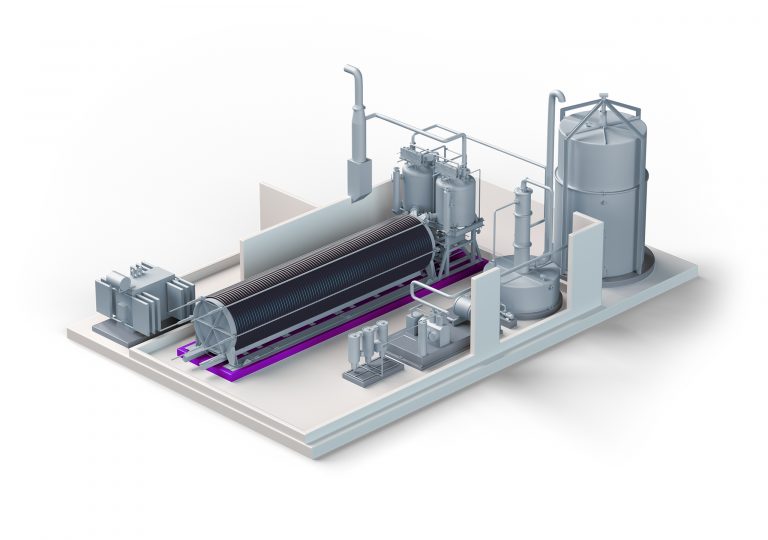

First Ammonia announces deal for 5GW of Topsoe electrolysers

US-based First Ammonia has announced a new reservation deal with Topsoe for delivery of solid-oxide electrolysers. Initially, First Ammonia will purchase 500 MW of SOECs from Topsoe’s new manufacturing plant in Herning, Denmark, with the option to expand to 5 GW over the lifetime of the agreement. That initial 500 MW will be deployed over two First Ammonia production projects, both targeting commercial operations in 2025: one in northern Germany, and one in southwest USA.

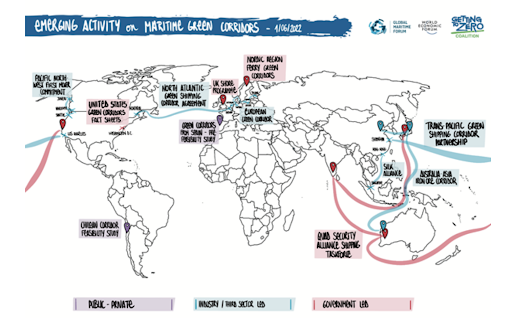

Ammonia Green Corridors - The Opportunity Is Now

Since the Clydebank Declaration was signed last December, the prospect of ammonia-fueled, green maritime corridors has been steadily rising. The Global Maritime Forum has just released a valuable discussion paper on potential definitions and approaches for green corridors. Recent announcements in Europe, Singapore, Australia and the Nordic countries demonstrate growing momentum. For maritime stakeholders to capture early learnings and best manage the complex task of alternative maritime fuel scale-up, the opportune time is right now.

Skovgaard renewable ammonia project orders electrolysers from Nel

The consortium developing the Skovgaard ammonia project has ordered an alkaline electrolyser system from Nel, bringing the 10 MW plant a step closer to reality. Skovgaard will be an important test case for hydrogen production directly from renewable energy, with no battery storage or firming to be used.

In other electrolyser news, German-based Sunfire and US-based Electric Hydrogen have received new funding to develop their technologies. Also in Germany, Siemens and Air Liquide will join forces to develop a GW-sized factory in Berlin, with 3 GW of PEM electrolyser units to be manufactured annually by 2025.