Ammonia Combustion

IHI’s Development of Ammonia Combustions Technologies / Fuel Ammonia and Hydrogen Solutions

Impact of ammonia as a fuel / co-fuel on NOx emissions

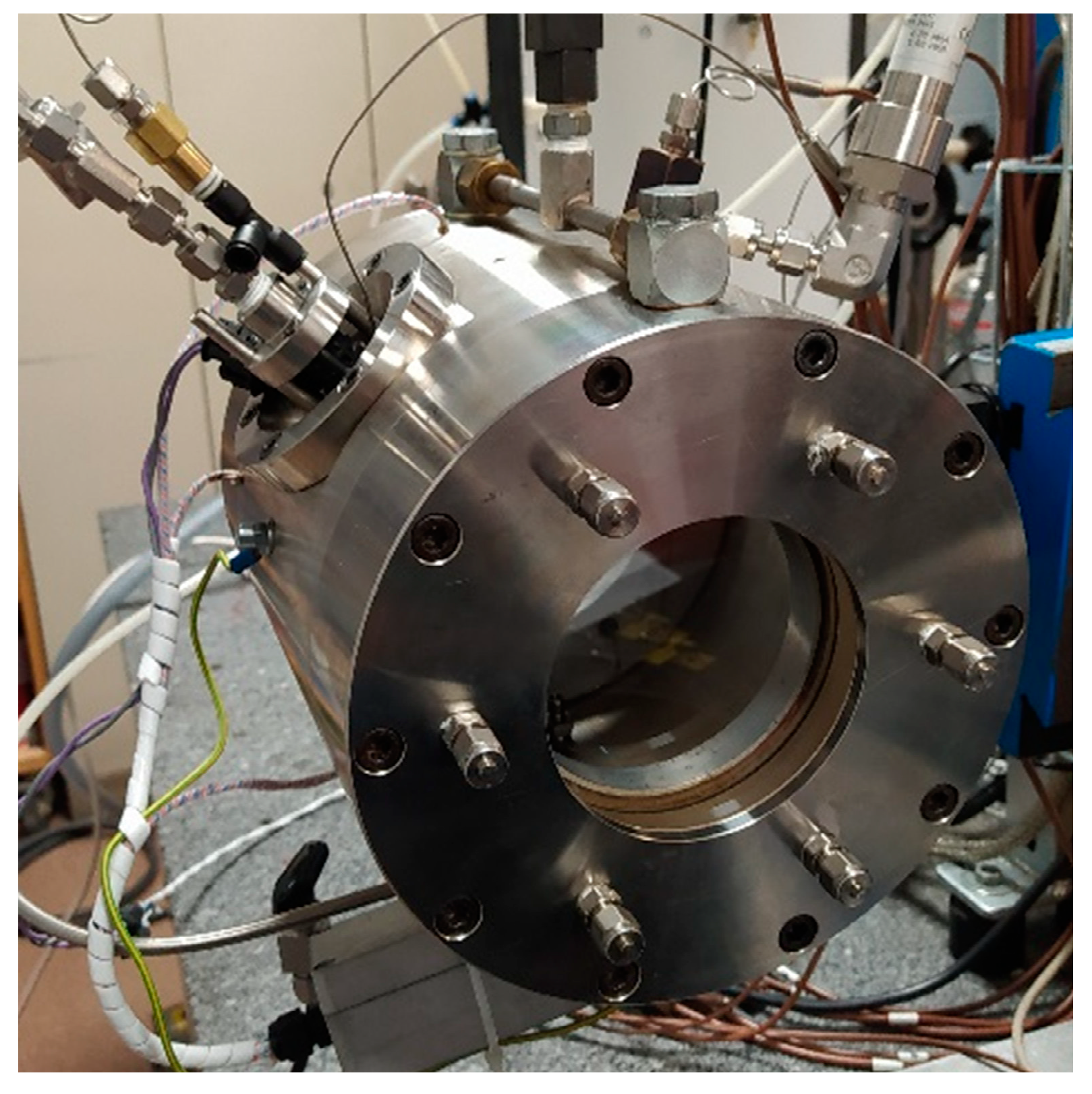

Ammonia combustion engines: latest research

The journey from the laboratory bench to the shop floor continues apace in 2021, as researchers deepen their understanding of ammonia combustion within engines. The team at Université d’Orléans has published several pieces of research already this year, with interesting results on operating limits, spray characteristics and flame propagation.

Production and utilization of green ammonia: KIER’s current status and future plans

Ammonia as an Energy Carrier: Leveraging technologies and infrastructure to decarbonise global energy systems

Doosan Heavy Industries, POSCO and RIST to develop ammonia gas turbines

Two members of the newly-launched Korean Green Ammonia Alliance - Doosan and POSCO - signed an MoU this week with the Pohang-based Research Institute of Industrial Science & Technology (RIST) to develop "Clean Ammonia-Fueled Gas Turbines".

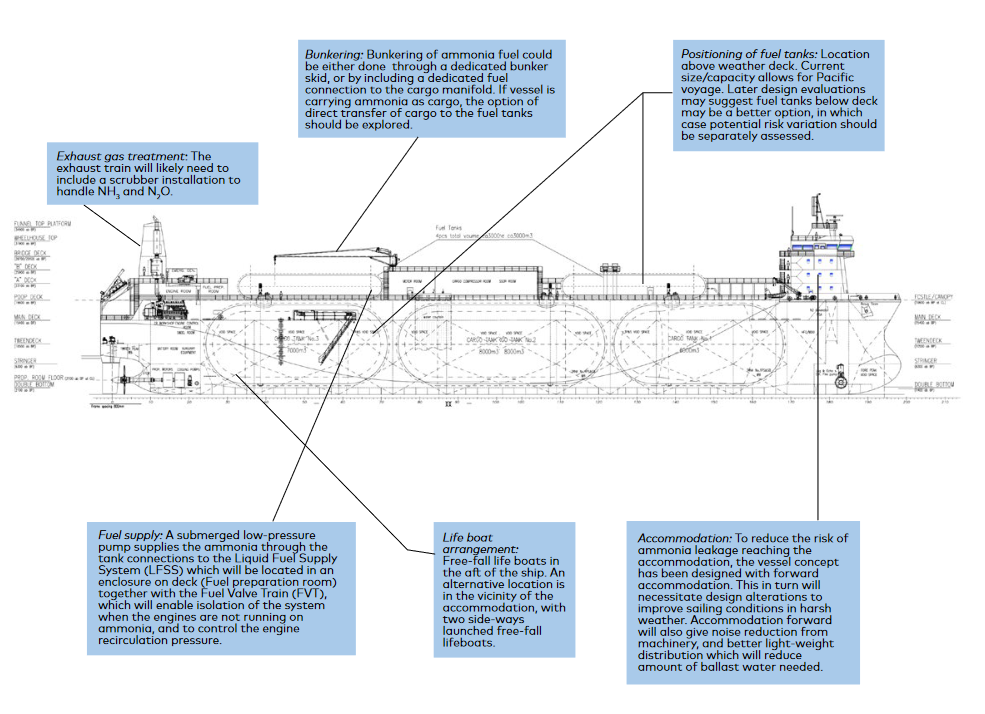

The Ammonia Wrap: no major obstacles for NoGAPS success and more

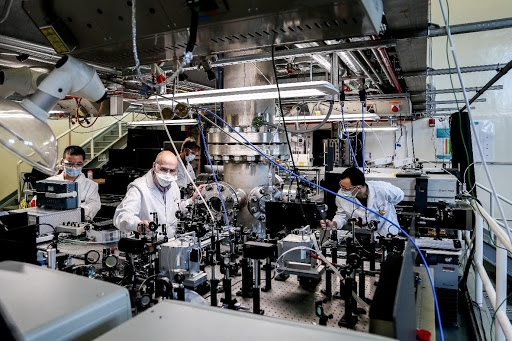

Welcome to the Ammonia Wrap: a summary of all the latest announcements, news items and publications about ammonia energy. This week: latest report from NoGAPS, Viking Energy project takes another step, more collaborations for Yara, thyssenkrupp to invest in cracking R&D, investment in clean hydrogen technology in the USA, world-first visualisation of ammonia combustion in a spark-ignition engine and our numbers of the week.

Cardiff-KAUST-Tohoku Young Researcher Workshop on Ammonia Energy

Organised by a panel of young researchers — and for young researchers — Cardiff University, KAUST and Tohoku University hosted a virtual workshop on ammonia energy. Each group showed their most recent research developments through the two-day event, attracting 50+ participants from the three groups alone. The event included research introductions from the research leaders of each group as well as quizzes, discussion rooms, prizes. Each group selected 6 early career presenters to feature their latest work in the topics of chemistry and microflow reactors, laminar and turbulent flames and applications. Taking advantage of the discussion sessions, this workshop hopes to promote large scale international collaboration and a researcher exchange programme in ammonia energy.

A Deep Dive into SIP “Energy Carriers” Ammonia Combustion Research (second half)

From 2014 to 2018 Bunro Shiozawa served as Deputy Program Director of the SIP “Energy Carriers” initiative in Japan. Over the last year he has published a ten-part series of articles that describe and reflect on the research supported by the initiative. Part 4 covers ammonia combustion technologies. The first half of the article was posted on September 23, 2020, in Shiozawa's English translation. The second half follows.