Ammonia Synthesis

Scaling flexible ammonia production in China

Explore two flexible renewable ammonia production projects in China: Topsoe's in Baotou, and Envision Energy's in Chifeng City. We also welcome the Institute for Sustainable Process Technology to discuss the scale-up of electrolyzer plants to the GW-scale.

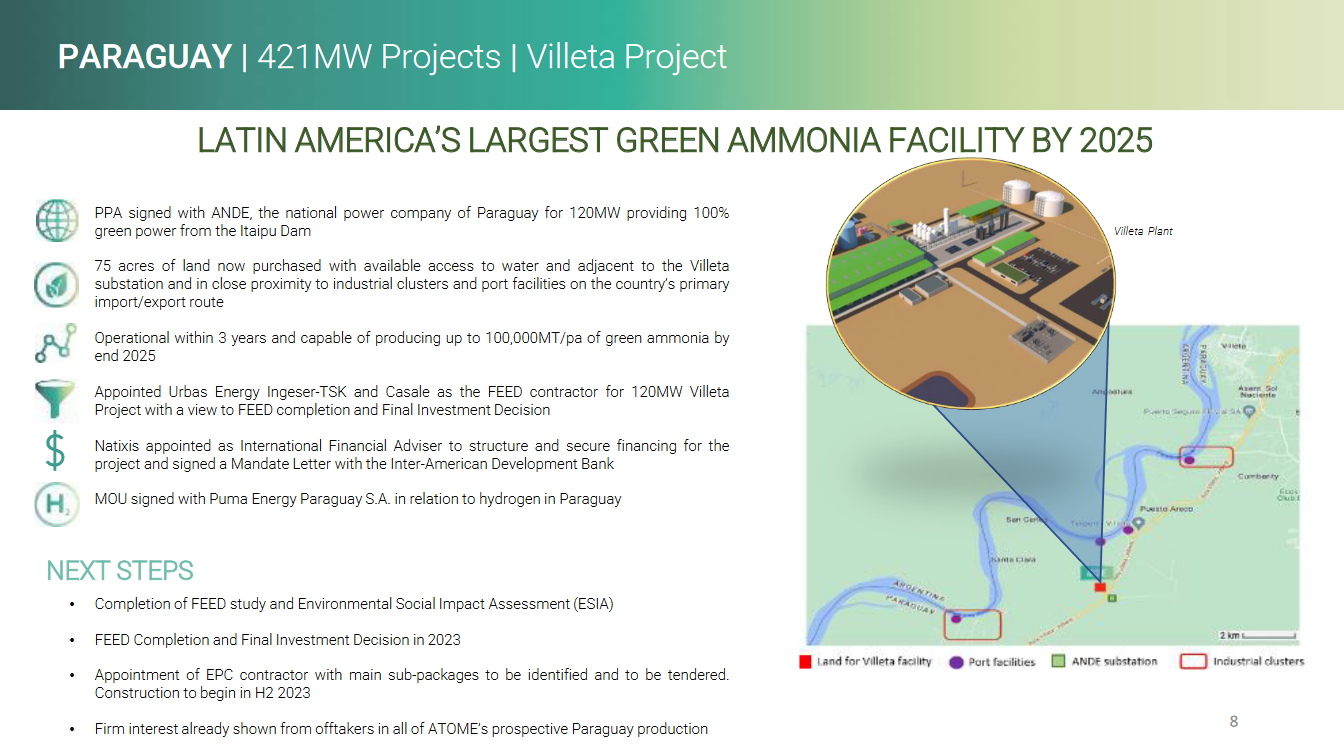

Hydro-electric ammonia: project design, engineering & technology selection

To design, build & operate a hydroelectric ammonia production plant fed by electrolytic hydrogen, what considerations need to be taken into account? Our recent episode of Ammonia Project Features explored this question, focusing on an upcoming project being developed in Paraguay by ATOME, URBAS and Casale. The use of surplus hydropower, existing industrial infrastructure, proactive engineering and commercially-available, flexible ammonia synthesis technologies all adds up to a less challenging task for developers, and a potential project template going forward.

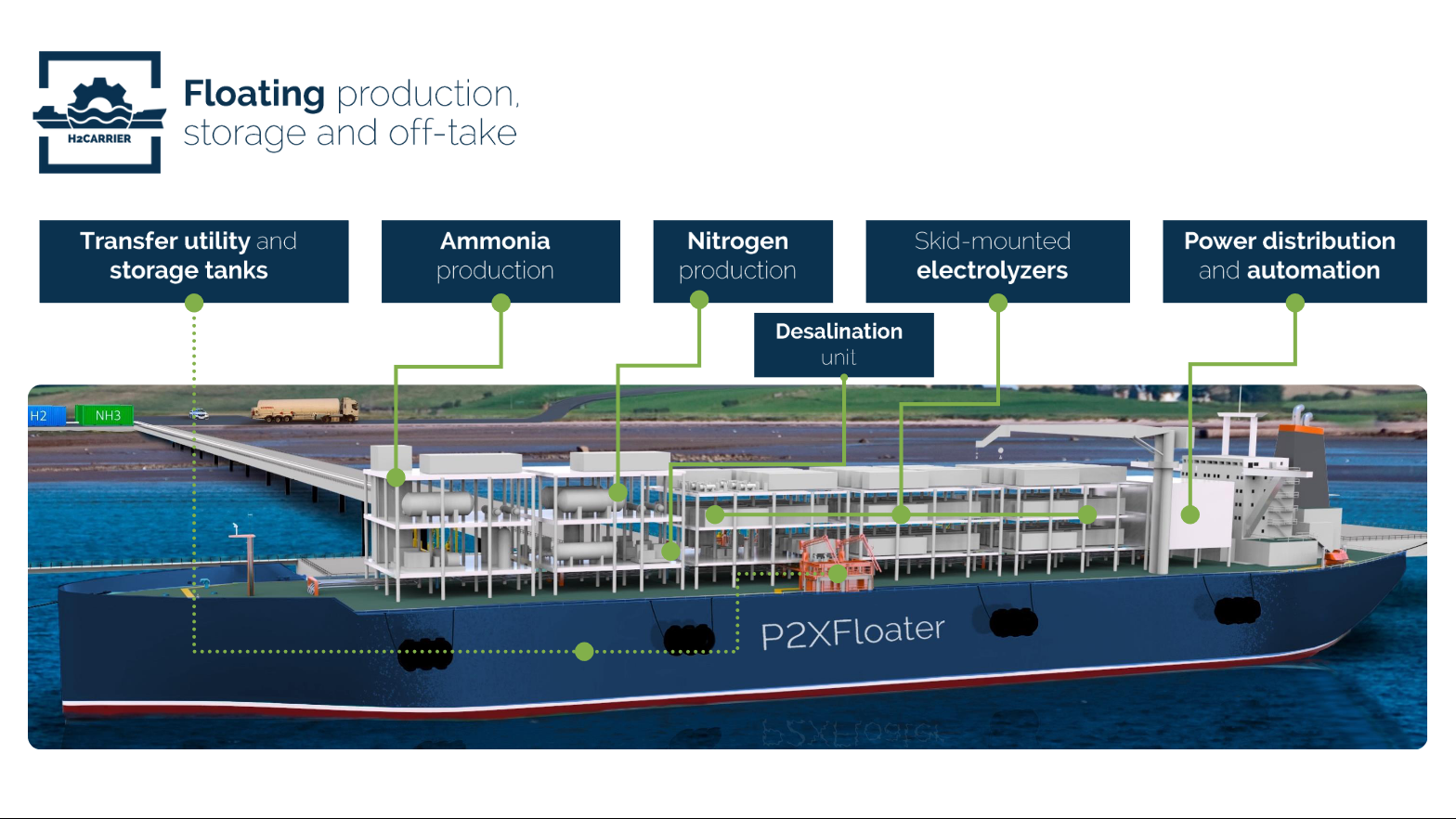

Enabling offshore production: jetty-less terminals & floating ammonia factories

Our last episode of Maritime Ammonia Insights featured new technologies being developed for the emerging offshore ammonia production industry. We explored SBM & Imodco’s jetty-less export terminal, H2Carrier’s P2X Floater vessel and CyaNH3’s FPSO hull design, as well as the unique opportunities on offer for floating ammonia producers.

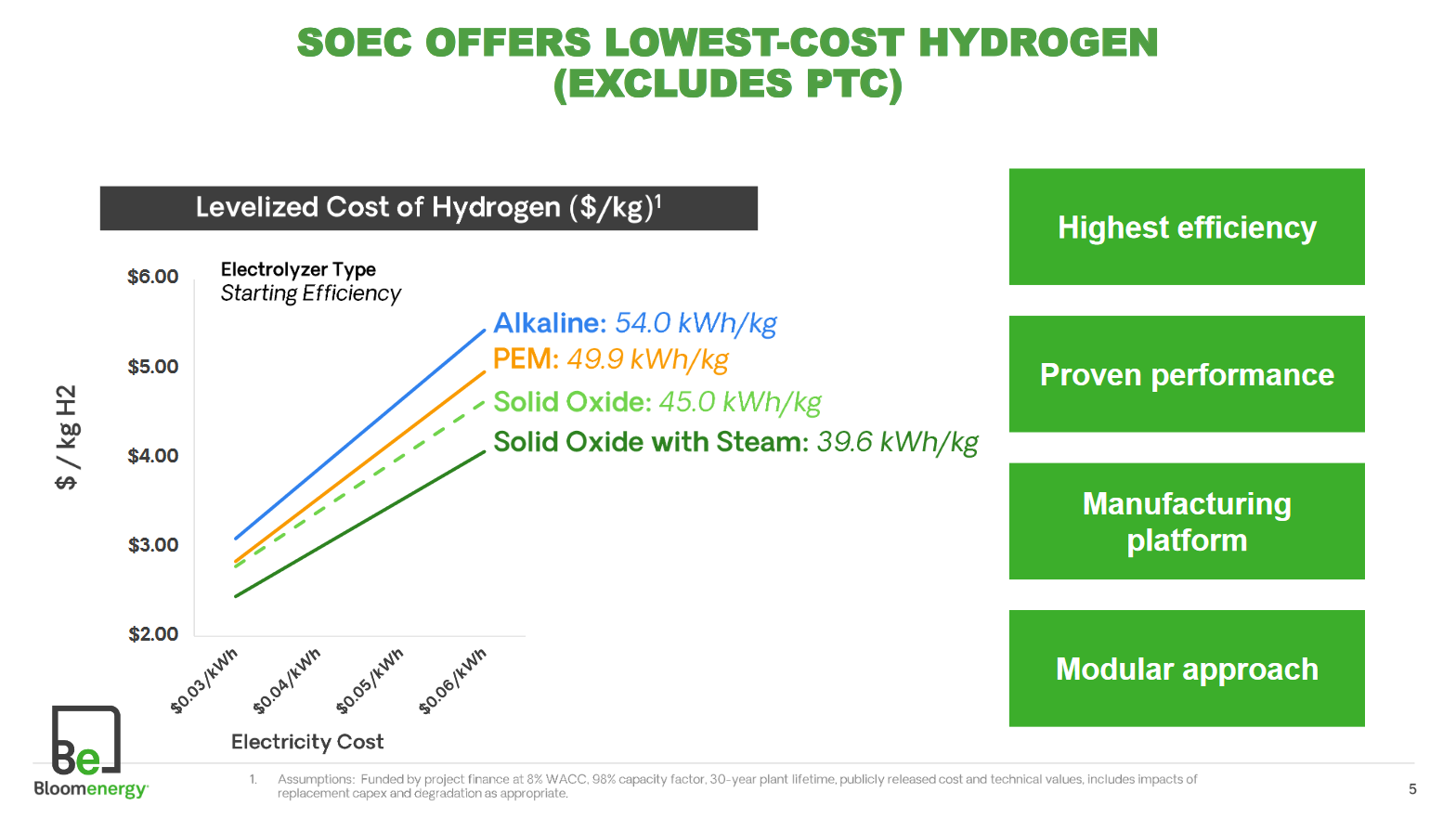

Coupling solid oxide electrolysis to ammonia production

In our January episode of Ammonia Project Features, we explored the current commercial status of solid oxide electrolysis, and its potential to be integrated with ammonia production. Rick Beuttel (Bloom Energy) and Jakob Krummenacher (LSB industries) also discussed the utilization of the technology in a new decarbonization project at LSB’s ammonia plant in Pryor, Oklahoma.