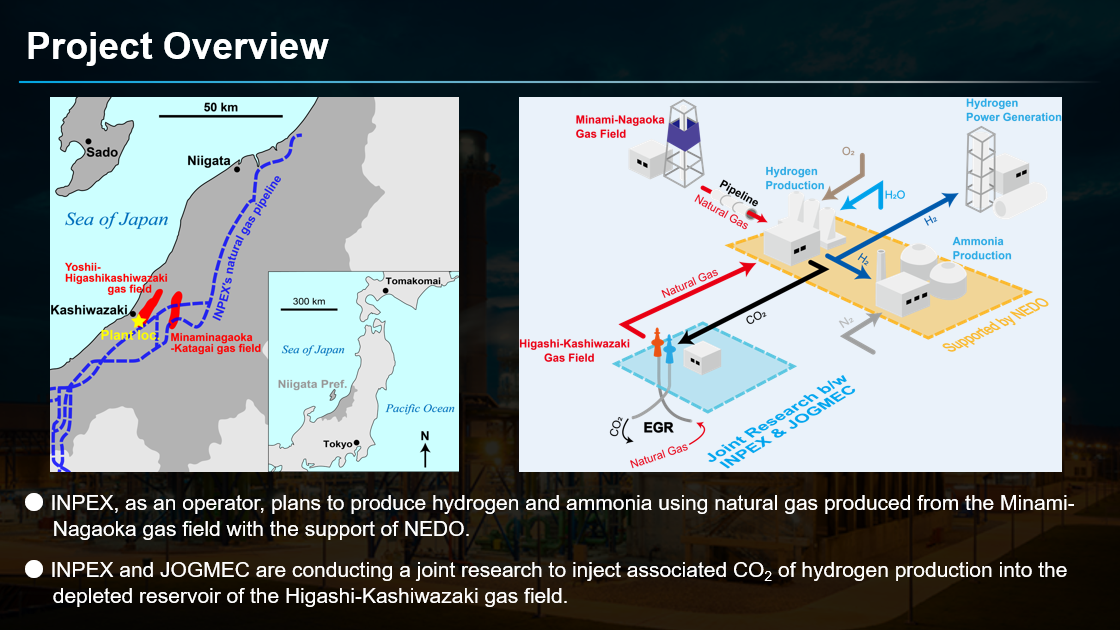

Demonstrating CCS-based ammonia technologies in Japan

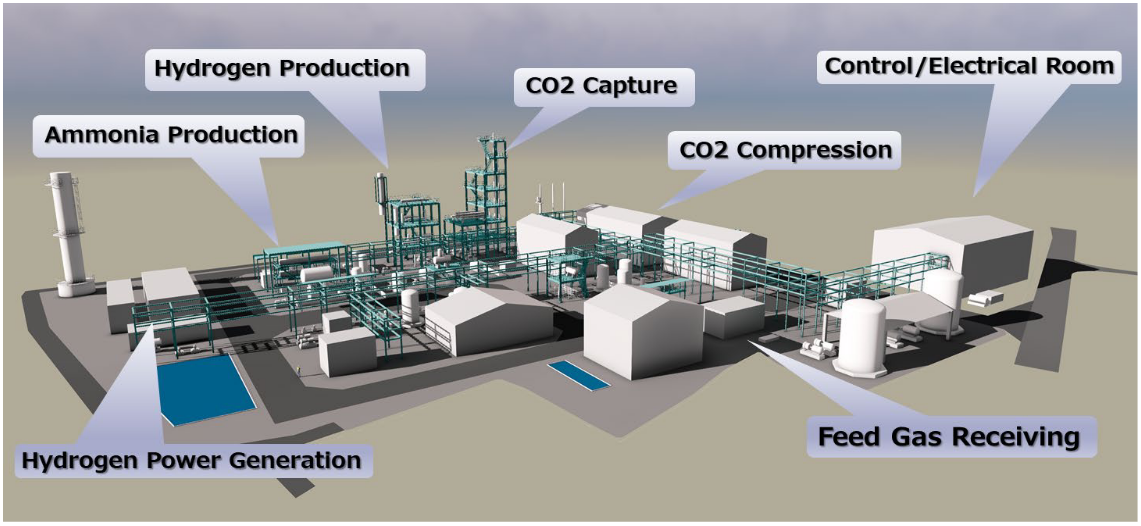

Our June episode of Ammonia Project Features focused on a new project in Niigata prefecture, which will demonstrate low-carbon, fossil-based ammonia production with a capacity of 500 tonnes per year. As part of the project, Japanese government organization JOGMEC will work with INPEX to develop enhanced gas recovery & CO2 sequestration monitoring technologies. Tsubame BHB will deploy its low-temperature, low-pressure ammonia synthesis technology based on an electride-supported catalyst developed at the Tokyo Institute of Technology.