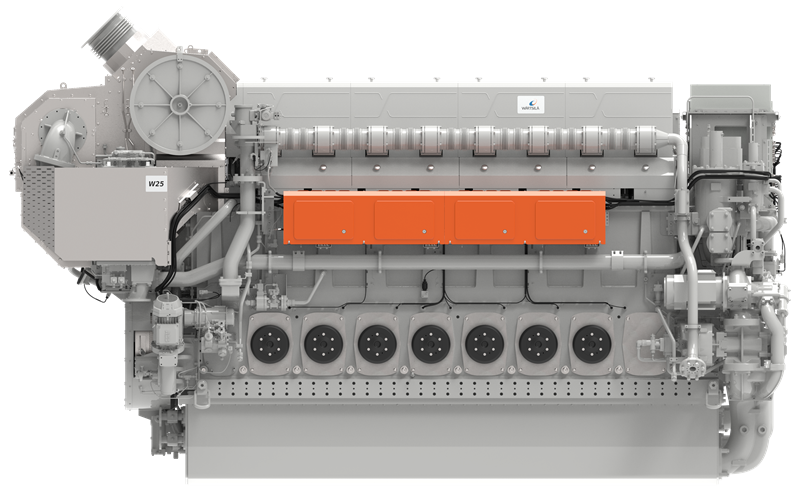

Mitsubishi Heavy Industries to explore ammonia-fired gas turbines in Singapore, Indonesia

MHI, Keppel Infrastructure and DNV have agreed to explore the feasibility and deployment of a 100% ammonia-fired gas turbine on Jurong Island, Singapore. In Indonesia, MHI and Bandung Institute of Technology will work together to demonstrate 100% ammonia firing with MHI’s H-25 Series, 40 MW gas turbine.