Ammonia-Fueled Solid Oxide Fuel Cell Advance at Kyoto University

By Stephen H. Crolius on July 20, 2017

Earlier this month the Eguchi Laboratory at Kyoto University announced advances in ammonia-fueled solid oxide fuel cell technology. The lab was able to produce a functioning fuel cell with a power output of one kilowatt. The device attained “direct current power generation efficiency” in excess of 50% and reached 1,000 hours of continuous operation. The announcement was reported by the Japanese Web site EE Times, a provider of “the latest information on leading-edge technologies and industry trends.”

Although the report mentioned the claim that the device is “the world’s largest power generation output of an NH3 fuel cell,” the longevity of the fuel cell may be the more important advance. In a review article from 2014, two authors from the University of Strathclyde in the UK state that “for direct ammonia SOFCs, the key challenge is the integration of robust redox stable anode to the fuel cell to improve the durability of the anode/electrolyte interface, which can sustain the local temperature change during the operation of the ammonia fuel cells and to avoid formation of nitrides.”

The Eguchi Laboratory has been working with nickel-based cermet as an anode material. Lab members published a paper in late 2015 reviewing their investigation of two specific materials in this family. At that time, the zirconia variant was judged inferior to the gadolinia variant in its catalytic properties. The zirconia variant was nonetheless taken forward into the recent work, perhaps because of superior durability.

At last September’s NH3 Fuel Conference, lab leader Koichi Eguchi described the current state of the group’s work as “200 W[att]-class stacks as well as button-type cells . . . applied as SOFCs.” The focus, he said, was investigation of three types of ammonia-fueled SOFC systems. One involved direct supply of ammonia to the fuel cell’s anode chamber. The other two involved fuel pretreatment with partial decomposition into diatomic hydrogen and nitrogen via catalytic and autothermal cracking methods respectively. A comparison of these systems was the topic of a paper published by lab members in March.

The fuel cell that is the focus of the current announcement involves direct supply of ammonia “to the SOFC stack.” With this approach, the lab was able to confirm that the “power generation characteristics” using ammonia “were at the same level as those of pure hydrogen.”

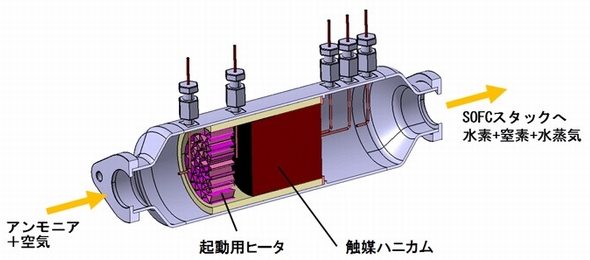

The autothermal cracking method was also referenced in the EE Times report as a technology that could support fuel cell applications that require modulation (as distinct from constant function at a steady rate). The EE Times stated that the cracker enabled “high-speed startup of 130 seconds” with an “outlet gas temperature of 500° C.” The report continued, “’When a mixed gas containing hydrogen generated in the reactor was supplied to the SOFC stack, we succeeded in generating 1 kW class power as well.’ The research group sees ‘technology demonstrating the possibility of high-speed activation without using external heating of NH3-based SOFC’”.

James Grieve, an NH3 Fuel Association Board member and SOFC proponent when he was Chief Scientist at the tier-one automotive supplier Delphi, took positive note of the Kyoto University group’s progress. “This work highlights the practicality of making SOFCs fuel-flexible to accommodate carbon-free fuels such as hydrogen and ammonia,” he said. “Kyoto’s SOFC results show that ammonia has similar efficiency and power density to hydrogen. Ammonia has considerable advantages as it is easier and safer than hydrogen to transport, store and use.”

Kyoto University’s work in this area is supported by the “Energy Carrier” element of Japan’s Cross-Ministerial Strategic Innovation Promotion Program (SIP). The Eguchi Laboratory has been cooperating with scientists from several Japanese companies including Noritake, Nippon Shokubai, Toyota Industries, Mitsui Chemicals and Tokuyama. IHI Corporation is included in the list of company affiliations in the recent announcement.