A new strategy for internal combustion of ammonia

By Stephen H. Crolius on November 30, 2017

Of all the devices that can convert the chemical energy in ammonia to electricity, gas turbines and fuel cells appear to be receiving the lion’s share of development effort, outstripping that devoted to ammonia-fueled internal combustion engines (A-ICEs). An Ammonia Energy review last year found a number of organizations with histories of work on A-ICE technology, but reports of progress have not been forthcoming.

It was good news, therefore, when a representative of a newly engaged group appeared at the NH3 Energy+ Topical Conference earlier this month and delivered a talk on an innovative A-ICE “combustion strategy.” Donggeun Lee from the Department of Mechanical Engineering at Seoul National University (SNU) delivered the paper, entitled “Development of new combustion strategy for internal combustion engine fueled by pure ammonia,” on behalf of his co-authors, Hyungeun Min, Hyunho Park, and Han Ho Song.

In a follow-up email, Song, an Associate Professor at SNU, said the group’s jumping off point was the “AmVeh” program of the Korea Institute of Energy Research (KIER). The KIER team reported at the 2014 NH3 Fuel Conference that they had successfully employed dual-fuel mixtures in both spark-ignition and compression-ignition engines. While the team was able to demonstrate the use of an ammonia-gasoline mixture in a functioning vehicle (the AmVeh), they said that “the final goal of the study is to implement a methodology to ignite ammonia-air mixture and have complete combustion without any use of the conventional fuels.”

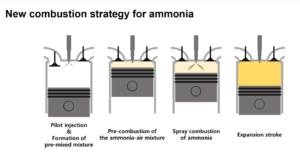

The SNU team decided to pick up this challenge. They judged that CI would be the best way to address ammonia’s particular combustion profile. Since several groups preceded them on the CI path, they were aware that an ammonia CI engine “typically requires as high compression ratio as 50:1.” (Conventional CI engines have compression ratios below 20:1.) Contemplation of this challenge led to the key expedient in their “combustion strategy:”

A small amount of ammonia is injected into the cylinder during intake process or early compression stroke. The ammonia injected forms the homogeneous mixture with air and auto-ignition of the pre-mixed lean ammonia-air mixture occurs near the end of the compression stroke. The auto-ignition increases the pressure and temperature inside the cylinder enough to burn the main spray injection of ammonia as in conventional diesel engine.

Lee et al, Development of New Combustion Strategy for Internal Combustion Engine Fueled By Pure Ammonia, 11/01/2017

In his presentation, Lee described the methodology the team is using to validate this approach. It is based on a motor industry innovation called “quasi-dimensional modeling” that incorporates both simulation and physical modules. Chemical reaction kinetics can be explored in the former; the spatial dynamics of injected fuel can be mapped in the latter. The model’s default parameters were taken from an off-the-shelf Hyundai diesel engine whose particular design lends itself to the implementation of an elevated compression ratio.

The team’s initial investigations focused on the quantity of ammonia in the pilot injection and the timing of the main injection relative to that of the pilot injection. The quasi-dimensional model allowed varying values of the parameters to be tested and ultimately led to the conclusion that the SNU combustion strategy would support stable operation of the engine, with, helpfully, a compression ratio of just 35:1.

The SNU project is titled the “NH3 Extreme-Compression Ignition Engine.” Extreme compression involves a series of consequential tradeoffs. On the positive side is efficient conversion of the chemical energy embodied in the fuel into kinetic energy. Indeed, in his email, Song said that a key motivation for the project is “the theoretically supported … possibility of achieving high efficiency in an internal combustion engine with extreme compression ratio.”

On the other side is the fact that nitrogen oxide (NO) formation is exacerbated by elevated pressure as well as temperature. To gauge the size of this problem, the team evaluated reaction kinetics at four distinct phases of the combustion cycle. They saw a surge in NO concentration with the temperature increase created by the pilot injection followed by a decrease when the ammonia in the main injection entered the cylinder. The conclusion, Lee said, is that NO can indeed be managed with fine adjustments to the quantity of material delivered in the pilot and main injections. Another tradeoff, though, is that minimizing NO formation narrows the window for the start of the main injection event – but, crucially, does not close it altogether.

Another consequence of extreme compression is the appearance of outsized mechanical forces. Song said one of the team’s current activities is construction of a physical engine test bench that can simulate the effect of a “drastically high compression ratio in a slider-crank-type (i.e. typical piston-connecting rod-crank shaft type) of internal combustion engine.”

Song said that the primary use case targeted by the team is the electricity-generation part of a renewable energy storage system:

“Our approach is firstly targeted at the use of pure ammonia to produce electricity in the proposed engine in a very efficient manner without the help of any combustion promoter, and our proposition is that this ammonia originates from the hydrogen produced by regenerative power sources, such as solar or wind, for easier energy storage and transportation. We try to avoid converting this hydrogen-storing ammonia back into hydrogen again before being used in an energy conversion device to produce electricity (as some researchers proposed), since such additional ammonia to hydrogen conversion might also cause additional available energy loss.”

The SNU results to date are promising, but Song is clear that there is a long way to go: “Regarding the milestones by the end of 2018, we possibly achieved the simulated extreme-compression ignition of ammonia engine operation then. We could understand the feasibility of such combustion, its efficiency of conversion, and pollutant emissions, especially concerning slipped ammonia and nitrogen oxides.”

The SNU abstract and presentation can be found on the 2017 conference webpage.