Ammonia combustion analysis: powertrains, turbines & power generation

By Julian Atchison on December 08, 2021

Performance of ammonia power trains in a maritime environment

A team from the University of Cambridge has shown merchant vessels are the strongest candidates for conversion to run on ammonia fuel, following detailed modelling of the outcomes of running four different classes of oceangoing vessel on an integrated ammonia powertrain system. More space is required for both the powertrain setup and ammonia fuel in order for the vessel to travel the same distance as if it were operating on conventional fuels. But, the cargo capacity losses of 4.4% for a New Panamax Carrier and 9.3% for a Gas Carrier could be feasibly offset by operators, especially if current vessel ranges can be maintained.

The authors note that operators of smaller vessels like Regional Ferries (which operate on less-efficient, more compact engines) would be unlikely to accept a 4.3% loss in passenger/cargo capacity and more frequent refueling required to run on ammonia. Some compromise between refueling frequency and capacity loss may make Ferries a candidate. Naval vessels like Frigates, where cargo-carrying capacity is specialised (aircraft hangers), would struggle to incorporate the extra space requirements, technology and fuel required for ammonia. Another option – maintain current fuel capacities and accept restricted range for the vessel – is definitely not feasible for smaller vessels.

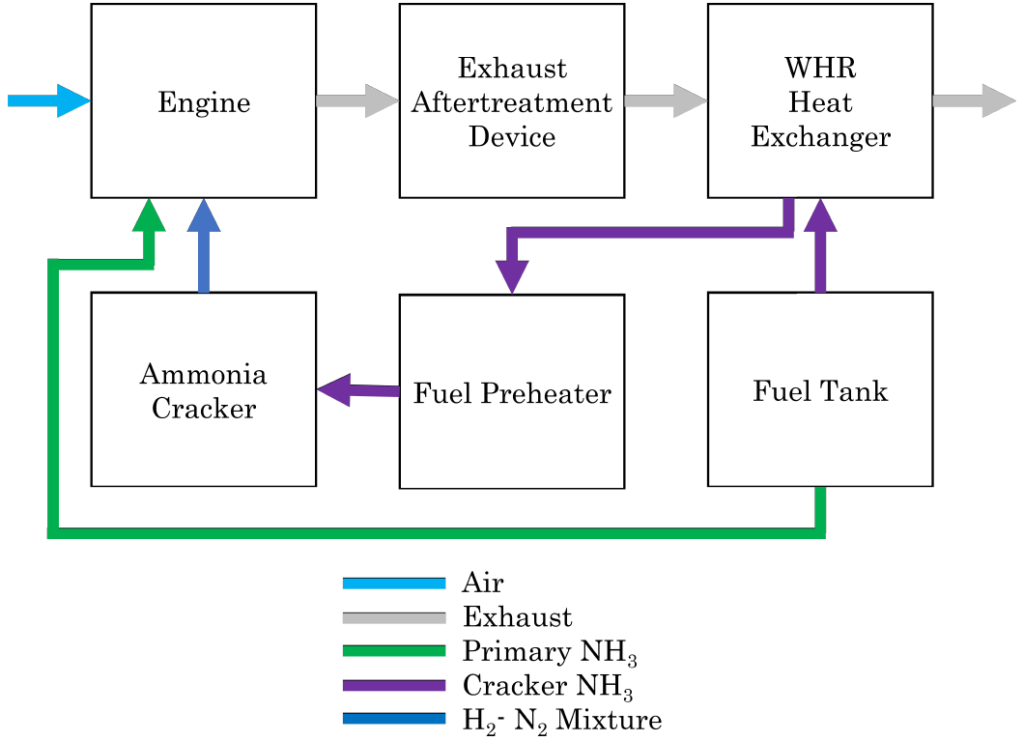

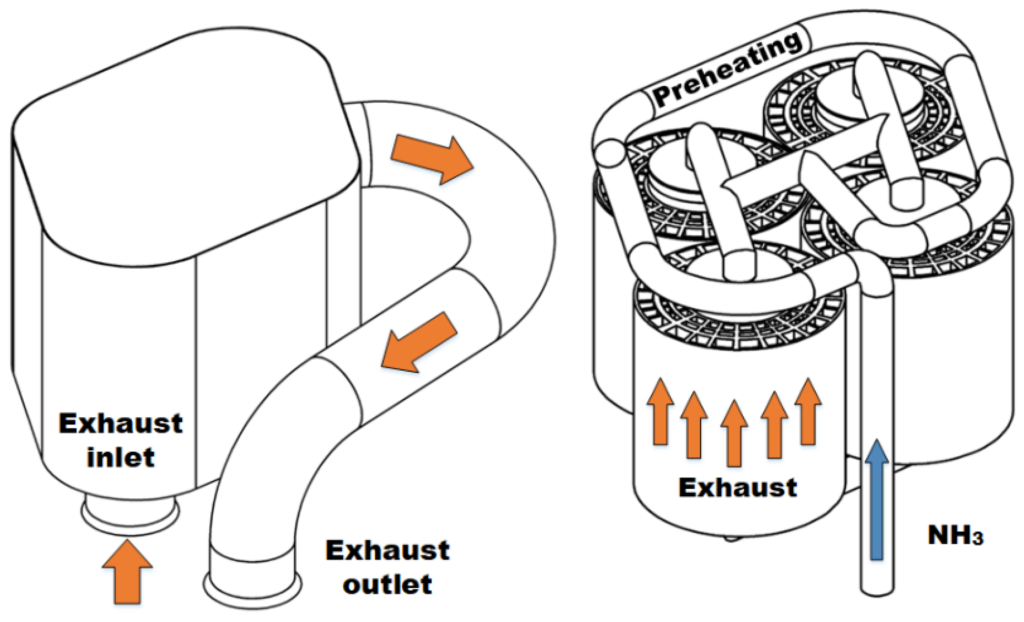

Efficient dual-fuel combustion in a compression ignition engine

Researchers at the University of Minnesota have successfully tested a thermochemical recuperation (TCR) reactor to improve the efficiency of a dual-fuel, diesel-ammonia compression ignition engine. Ammonia slip in the engine exhaust stream was cracked in the TCR reactor (using exhaust heat) into a highly combustible H2–NH3 mixture, which could be fed back into the engine and displace more diesel fuel.

But, as diesel replacement increased, so did the level of ammonia slip and the formation of NOx species. In good news, the observed NH3-to-NOx ratios at the engine-out point were suitable for passive selective catalytic reduction. The researchers believe inclusion of design features (and/or adjustments to catalyst formulas) to ensure additional treatment of the exhaust would be straightforward for future studies.

Modelling ammonia combustion in gas turbine flames

A global team led by Cardiff University researchers has revealed some of the inner workings of ammonia combustion in swirl flames (“swirling” flows are the principal way of stabilising flames in current commercial gas turbines). In order to minimise NOx formation and avoid unburnt NH3, a better understanding of combustion mechanisms, chemical kinetics modelling and detailed emissions analysis is required across a range of ammonia fuel blends.

The authors report that, as molecular ammonia is broken down to release energy (the NH3 → NH2 → NH pathway), radical species are also produced that result in the formation of NO and N2O. NO2 is also formed near these localised production “peaks”, but is mostly consumed in the flame. Higher inlet temperatures and pressures resulted in more ammonia breakdown, but also higher NO formation. The authors suggest more research into the so-called NO “reburn” reactions is critical, as these reactions control the formation of N2O – the NOx species with the highest greenhouse potential.

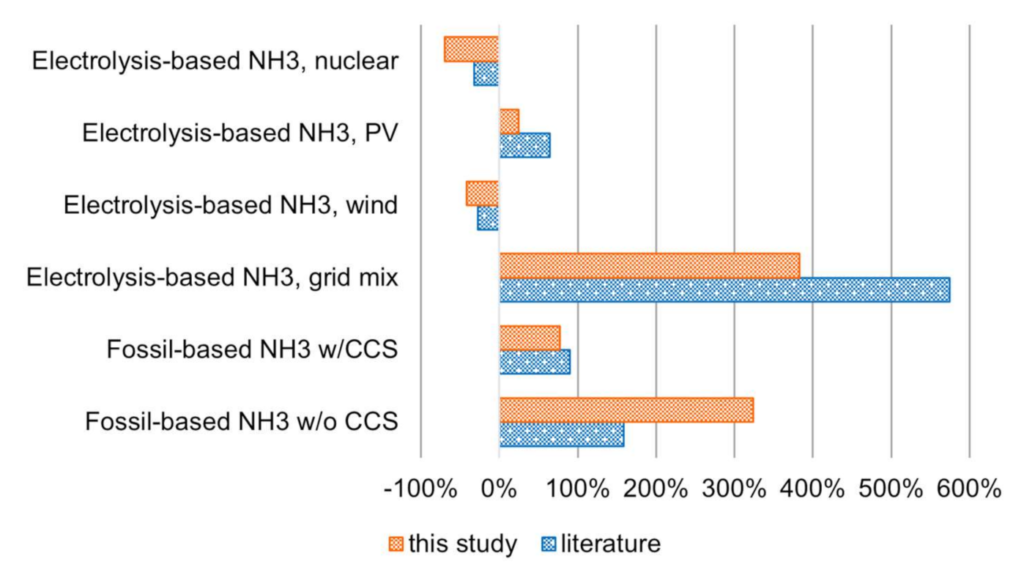

Estimating a carbon footprint for ammonia-based electricity

A global team (including AEA Technology Manager Kevin Rouwenhorst) has produced a cradle-to-gate, environmental assessment for ammonia production and ammonia-based electricity generation:

The results show that electrolysis-based ammonia from renewable and nuclear energy have a better profile in terms of global warming potential (0.09–0.70 t CO2-eq/t NH3), fossil depletion potential (3.62–213.56 kg oil-eq/t NH3), and ozone depletion potential (0.001–0.082 g CFC-11-eq/t NH3). In addition, surplus heat for district or industrial applications offsets some of the environmental burden, such as a more than 29% reduction in carbon footprint. In general, ammonia-based combined heat and power production presents a favorable environmental profile, for example, the carbon footprint ranges from −0.480 to 0.003 kg CO2-eq/kWh.

Abstract from Boero et al., “Environmental Life Cycle Assessment of Ammonia-Based Electricity“, Energies, Oct 2021.

The authors conclude that only electrolysis-based ammonia from renewable or nuclear pathways will significantly contribute to the decarbonisation of the power sector. However they note that the environmental impacts of nitrogen emissions, the energy footprint of the Haber-Bosch process and ionising radiation from nuclear sources will all need to be mitigated if renewable and nuclear ammonia is to have a totally positive impact.