Ammonia cracking technologies gather traction across Europe

By Geofrey Njovu on April 03, 2023

Air Liquide: Port of Antwerp

Air Liquide has announced the construction of an industrial-scale ammonia cracking pilot plant in the Port of Antwerp, Belgium. Using Air Liquide’s proprietary technology, the plant will convert ammonia into hydrogen with an “optimised carbon footprint”. Operations at the Port are planned to begin in 2024.

Air Liquide’s highly efficient Ammonia Cracking process uses Air Liquide’s proprietary next-generation reactor tubes heat-integration technology. This technology allows for the highest possible ammonia to hydrogen conversion yield and zero direct CO2 emissions.

Ammonia cracking in brief, a fact sheet included in Air Liquide’s press release, 23 March 2023

Ammonia cracking complements Air Liquide’s already thorough portfolio of hydrogen technologies and adds yet another technological solution to enable the development of a hydrogen global market. More than ever, the Group is committed to making hydrogen a key element of the fight against climate change, in particular for the decarbonization of heavy industry and mobility.

Michael J. Graff, Executive Vice President, Air Liquide Group in his organisation’s press release, 23 March 2023

AFC Energy: UK

AFC Energy launched its new ammonia cracker technology platform that will “revolutionise” ammonia cracking by enabling renewable hydrogen production at scale. Two key attributes of the platform – a modular design and low-cost system architecture – means that the technology is readily scalable. AFC Energy sees this as necessary to meet rapidly growing demand for clean hydrogen power in off-grid applications, especially in hard-to-abate sectors such as maritime and stationary power. AFC Energy’s most recent commercial solution in the ammonia-fueled, off-grid space – the “Power Tower” – was launched in April last year.

AFC Energy’s new ammonia cracking technology platform takes us into the hydrogen generation market facilitating renewed energy security and reliability. Clean ammonia is affirmed as a preferred means of transporting hydrogen to end users, particularly in Europe and Asia, and now AFC Energy is targeting these key markets to enable a faster, more widespread adoption of hydrogen where storage and transportation challenges might otherwise present short-term challenges.

Adam Bond, AFC Energy CEO in his organisation’s press release, 23 March 2023

Linde & Aramco: northern Germany

The pair announced that they have signed an agreement to jointly develop ammonia cracking technology. The technology will be based on a new cracking catalyst jointly developed by Aramco and the King Abdullah University of Science and Technology (KAUST). In addition, Aramco and Linde Engineering plan to build a demonstration plant in northern Germany to showcase the new technology in an industrial setting.

This agreement is part of our ongoing technology and business development efforts to establish a commercially viable lower-carbon hydrogen supply chain. We believe the advanced ammonia cracking technology we are co-developing with Linde Engineering will play a key role in realizing our objectives.

Ahmad Al-Khowaiter, SVP and CTO at Aramco in Linde Engineering’s press release, 17 March 2023

Effective ammonia cracking technology supports the world’s urgent need for decarbonization. By completing the missing link in the export chain, cleaner energy can be shipped from regions with high renewable and clean energy potential to those with more limited resources. We look forward to working closely with Aramco to develop and commercialize this important technology, creating new business opportunities for Linde Engineering and Aramco.

John van der Velden, SVP Global Sales & Technology at Linde Engineering in his organisation’s press release, 17 March 202323

The above projects are a continuation of ammonia cracking momentum from the tail end of last year. In December, just north of Antwerp at the Port of Rotterdam, a feasibility study into the establishment of an onsite, million-tonne-per-year ammonia cracker was announced. The study, whose findings are due early this year, is being led by a consortium of eighteen partners including Air Liquide, Aramco, Linde and other big names in the energy sector.In Germany, Air Products and Mabanaft are developing ammonia import and distribution infrastructure at an existing tank terminal at the Port of Hamburg. Ammonia conversion to hydrogen at this facility is expected to commence in 2026.

Cracking: a pathway to decarbonise brick manufacturing, shipping and on-land vehicles

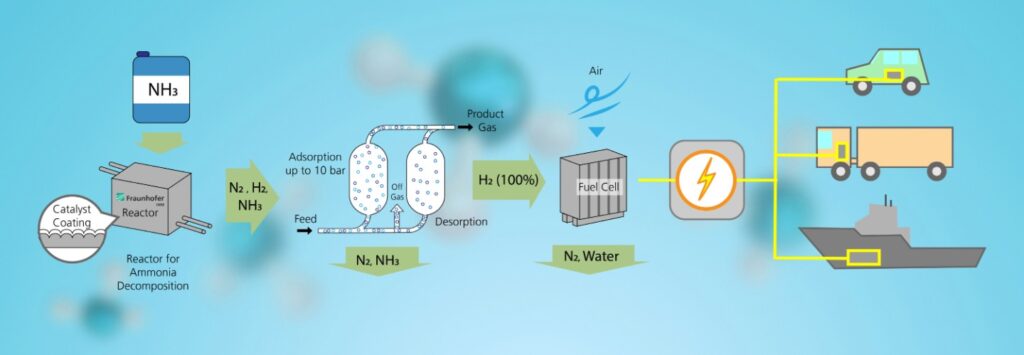

Researchers at the Fraunhofer Institute for Microengineering and Microsystems are developing a range of ammonia-based systems that aim to decarbonise several industrial processes. Newly released research focuses on using ammonia cracking technology in Power-to-X systems as CO2-free alternatives in the brick firing process, and a source of renewable hydrogen in fuel cells for on-land vehicles and ship engines.

An alternative to fossil fuels is power-to-X fuels, which are synthesized from electrolysis-based hydrogen. The most important power-to-X fuel is currently hydrogen itself. However, before hydrogen can be utilized as an energy source on a widespread basis, there are still some considerable hurdles that need to be overcome in terms of its transportation and storage. These include either high space requirements for its storage or other energetically unfavorable conditions. Ammonia (NH3) could become an alternative solution to allow the required hydrogen to be stored and transported with ease.

Dr. Gunther Kolb, Energy division head and deputy institute director at Fraunhofer IMM in his organisation’s press release, 15 February 2023

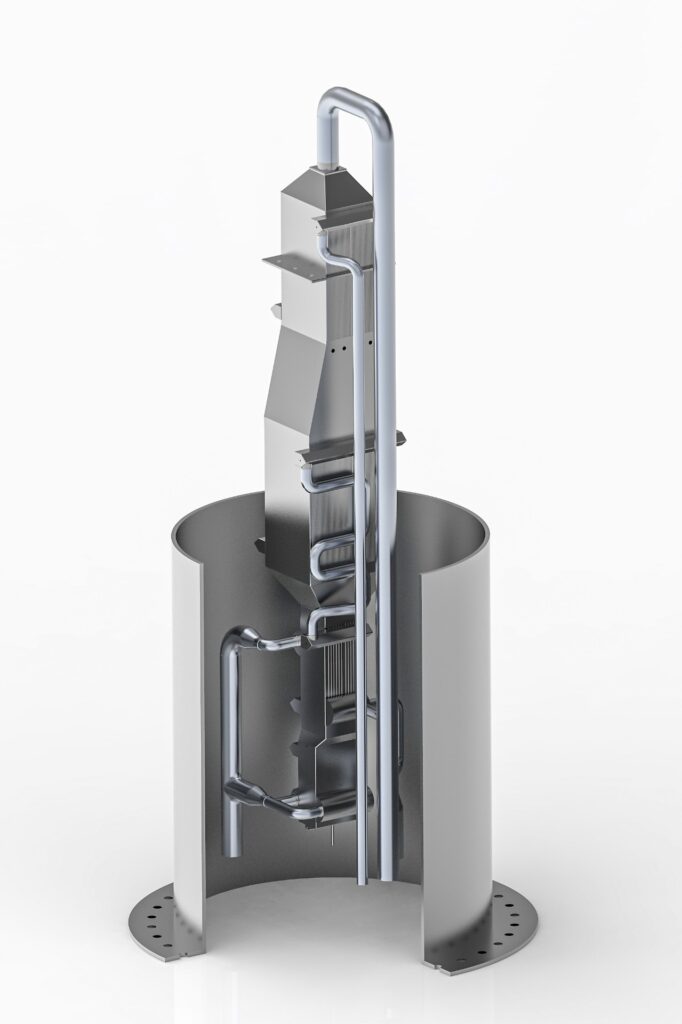

For fuel cells, Fraunhofer IMM is developing the AMMONPAKTOR, an ammonia cracking system based on novel catalysis and microstructured reactor technology. The system will produce and purify hydrogen from ammonia, which will be used in PEM fuel cells. The researchers are aiming to make the reactor design compact and more efficient than conventional technologies. This is advantageous especially for mobile and space-constrained applications. Currently under development, the second iteration of the cracking reactor has a throughput of 25/kg/hour of ammonia and produces 70 kg of pure hydrogen daily.

Additionally, together with 13 European partners in the ShipFC project, Fraunhofer IMM researchers are developing the world’s first ammonia-based fuel cell system for the maritime industry.