Certified renewable, bio ammonia incorporated into new supply chains

By Julian Atchison on December 05, 2023

Fertiglobe shipment exported to India, used in laundry powder production for Unilever

Produced at the Egypt Green project in Ain Sokhna, Egypt, a shipment of ISCC PLUS-certified renewable ammonia from Fertiglobe has reached the V.O. Chidambaranar Port in Tamil Nadu. The shipment was sent to Tuticorin Alkali Chemicals and Fertilisers (TFL), who used the ammonia to produce synthetic soda ash, before delivering the key feedstock to Unilever for laundry powder manufacturing. Hindustan Unilever & Fertiglobe have entered into a formal partnership to demonstrate the low-emissions supply chain, with renewable ammonia at its centre. As part of this pilot, carbon capture & utilisation and switching boiler fuels from coal to cashew kernels will also reduce emissions in the soda ash production process. Around 2,000 tonnes of renewable ammonia from Egypt Green will be imported this year for the pilot.

This exciting development is at the forefront of the home care industry’s utilising green ammonia as an emerging decarbonisation tool. This is one of the first examples of how it can be used to reduce CO2 emissions for an established industrial process.

Ahmed El-Hoshy, CEO of Fertiglobe and OCI Global in Hindustan Unilever’s official press release, 14 Nov 2023

The pilot addresses greenhouse gas emissions at every stage of the product’s (soda ash) manufacture and we believe it is a world first. Doing this while delighting consumers with great, affordable products is at the heart of our strategy.

Deepak Subramanian, Home Care General Manager, Unilever, South Asia in his organisation’s official press release, 14 Nov 2023

To drive the emission reductions required in the chemicals industry, we are working together to develop new technologies and processes. We’re excited to be partnering with Unilever to produce industry-leading near-zero emissions synthetic soda ash with a view to it being scaled up.

Ashwin Muthiah, Chairman of the TFL Group in Hindustan Unilever’s official press release, 14 Nov 2023

Globally, Unilever aims to reach net-zero for its Scope 1 and 2 emissions by 2030. Pilot demonstrations like this one will help tackle Scope 3 emissions, including the carbon intensity of ingredients purchased from suppliers like ammonia and soda ash. Unilever reports that 60% of its overall emissions comes from purchased ingredients & feedstock production, but this figure is closer to 80% for its “home care” business. By 2039, Unielver aims to reach net-zero emissions across its entire supply value chain.

Bio-ammonia for PLEXIGLAS® production

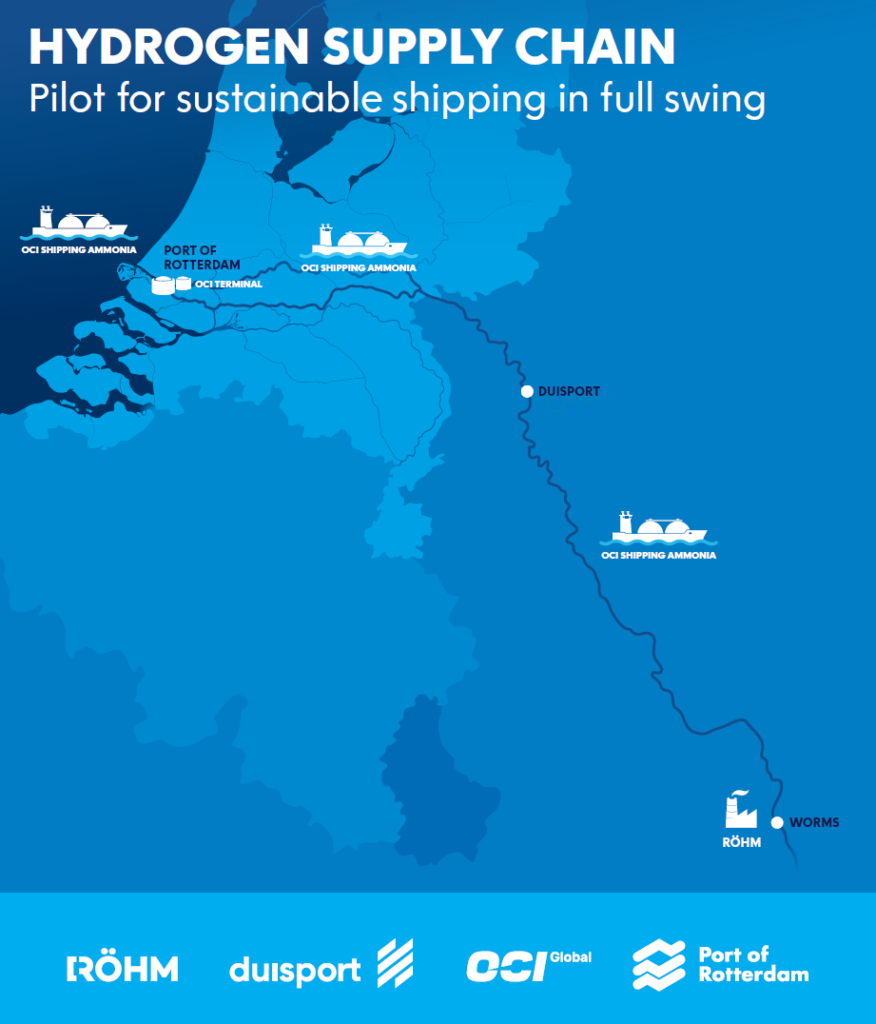

ISCC PLUS-certified bio-ammonia will be used to produce methylmethacrylate (MMA), a key feedstock in PLEXIGLAS® production. OCI Global produces bio-ammonia in the Netherlands, and will supply ammonia to Röhm for MMA production at manufacturing sites in Worms and Wesseling (Germany). The first shipment was delivered this month, with the delivery witnessed by King Willem-Alexander of the Netherlands. Earlier this year, OCI began supplying bio-ammonia to the food and drinks sector in the UK, supporting the production of lower carbon wheat and barley malt. Expansion of OCI’s ammonia import terminal at Rotterdam will also increase its ability to supply ammonia to key industrial supply chains in Europe.

This delivery of our bio-ammonia shows our pivotal role in developing the hydrogen corridor to enable the supply of lower carbon ammonia across Europe, from the Port of Rotterdam. Through partnerships with other industry leaders like Röhm, we’re able to continue to make first-moves and prove the case for lower carbon products in existing value chains, and we’re excited about the opportunity we have ahead of us to work with other industrial customers to do this. The industrial sector represents around 20% of the global ammonia market today. By converting this sector to lower carbon ammonia, we can help to create a future that allows for the continued production of essential downstream products in a sustainable way.

Ahmed El-Hoshy, CEO, OCI Global in his organisation’s official press release, 15 Nov 2023

Ammonia is a central feedstock for the manufacture of these methacrylic products such as Plexiglas, Degalan and Degaroute roadmarkings. We therefore are excited to join this partnership and take a significant step towards the decarbonization of our processes and products. A low carbon alternative of ammonia made from biogas allows us to manufacture in our ISCC PLUS certified plants Methacrylate based monomers, molding compounds and resins, in order to deliver sustainable products and solutions for our customers in the industries we serve.

Hans-Peter Hauck, COO at Röhm in OCI Global’s official press release, 15 Nov 2023

For ISCC-PLUS certification, only hydrogen produced by renewable electricity & electrolysis is considered compliant, with nitrogen to be obtained from ambient air by pressure swing adsorption. In the case of bio-ammonia, ISCC-compliant bio-methane feedstock must be used, with sources including biodegradable waste, industrial residues and landfill gas.

The two announcements join a number of supply chains which have now incorporated low-carbon and renewable ammonia, including:

- Potato chips produced by Lays (PepsiCo)

- Beer produced by Heineken

- and produce from northern Europe’s largest agricultural cooperative, Lantmännen