Development of Technologies to Utilize Green Ammonia in the Energy Market – Update on Japan’s SIP Energy Carriers

By Trevor Brown on November 30, 2018

At the recent NH3 Energy Implementation Conference in Pittsburgh, USA, the keynote speech was given by Shigeru Muraki, Program Director of Japanese government’s SIP Energy Carriers project. Muraki is also Chairman of the Green Ammonia Consortium, which will assume responsibility for coordinating the development and deployment of ammonia energy technologies in Japan when the SIP concludes in April 2019.

Given both these roles, Muraki was well placed to address not only the recent years of intense research and development in Japan, but also the near-term roadmap for commercial deployment of ammonia energy technologies.

The keynote speech began by quoting Prime Minister Abe’s speech at COP21 in November 2015, when the Paris Agreement was launched. Abe’s words explain almost entirely the motivation for ammonia energy research and development in Japan: “The key to acting against climate change without sacrificing economic growth is the development of innovative technologies.” As we’ve written here before, Japan is explicit in its aim of establishing a first mover advantage in hydrogen energy technologies, enabling its domestic industries to export their technologies to the world.

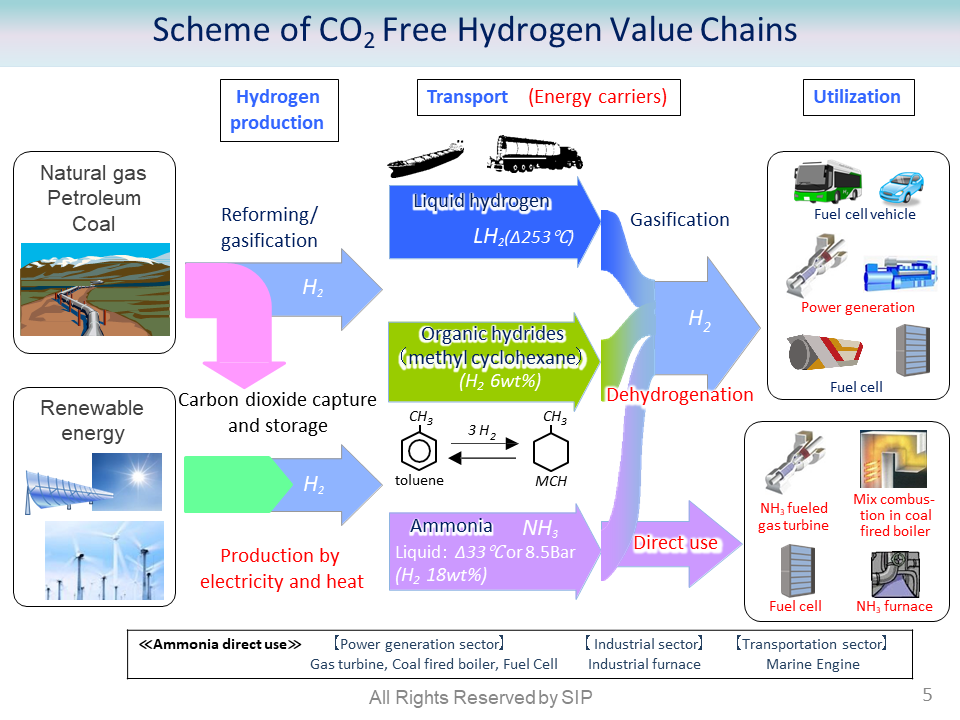

The SIP Energy Carriers project has funded research into technologies for three viable energy carriers: liquid hydrogen (LH2), organic hydrides (specifically methyl cyclohexane, MCH), and ammonia.

For those unfamiliar with the SIP project, Japan is a major energy importer, highly reliant on other nations for energy production, now and in the future. This reliance on imports is what drives the focus towards carbon-free technologies that can be not only produced and consumed at scale, but also transported across continents.

Hydrogen does not liquefy easily (−253 °C), making the storage and transportation of hydrogen technically feasible but notoriously expensive: both capital intensive and energetically inefficient. By contrast, ammonia does liquefy easily (−33 °C) and, moreover, is more hydrogen dense than hydrogen itself: a tank of liquid ammonia contains more hydrogen atoms than the same size tank of liquid hydrogen. For the purposes of national energy imports, therefore, hydrogen can be more economically transported in the form of ammonia, even after accounting for chemical conversion losses.

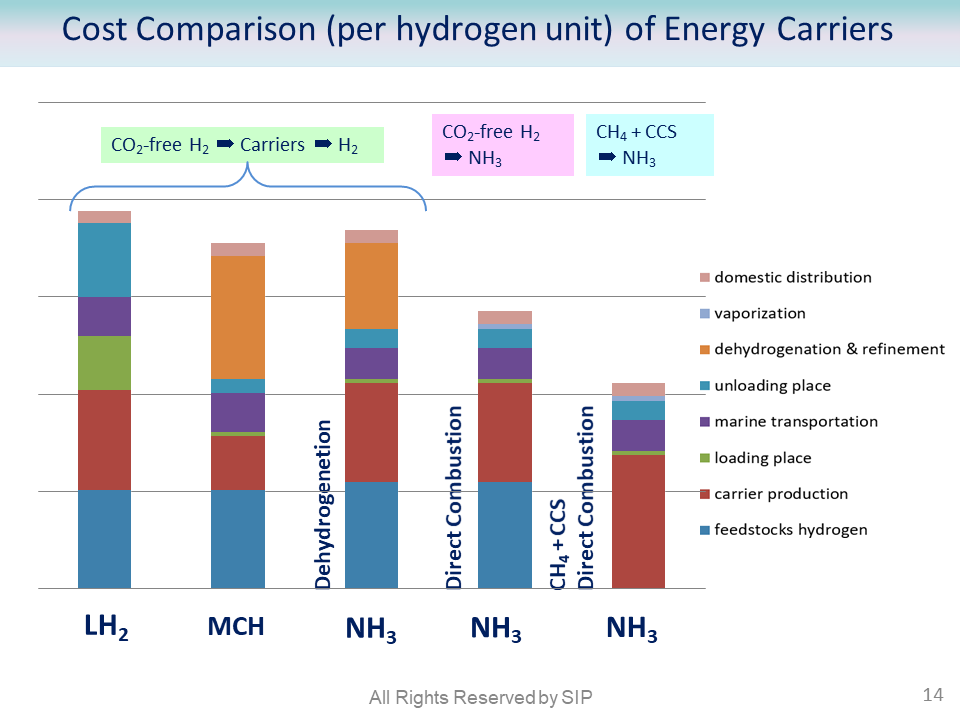

Muraki presented an important chart, “The Cost Comparison (per hydrogen unit) of Energy Carriers,” that demonstrated two further truths.

First, the economics of carbon-free energy imports can be improved by using ammonia as a direct fuel, avoiding the final chemical conversion from ammonia back to hydrogen. The option of using ammonia as a direct fuel is not acceptable in all markets, but looks to be favored initially in the utility-scale and industrial power generation. This flexibility – by which ammonia can be used either as a hydrogen source or as a direct fuel – makes ammonia an advantaged energy carrier.

Second, these economics can be further improved by combining the conventional ammonia production process, which consumes fossil fuel feedstocks, with sequestration of the carbon dioxide emissions. Per hydrogen unit, the cost saving from using the conventional process with sequestration (CH4+CCS) is roughly 25% relative to the cost of producing renewable ammonia. Renewable ammonia production technologies are currently immature and their costs are expected to fall, in line with anticipated cost savings in electrolyzer plants and the ongoing drop in renewable power generation costs. This means that conventional ammonia (with carbon sequestration) has a role as an advantaged “bridge” technology. Japanese importers can strike supply agreements today, with existing ammonia producers, to import low-carbon fossil ammonia in the near-term, while Japanese R&D teams mature the technologies necessary to produce truly renewable, carbon-free ammonia.

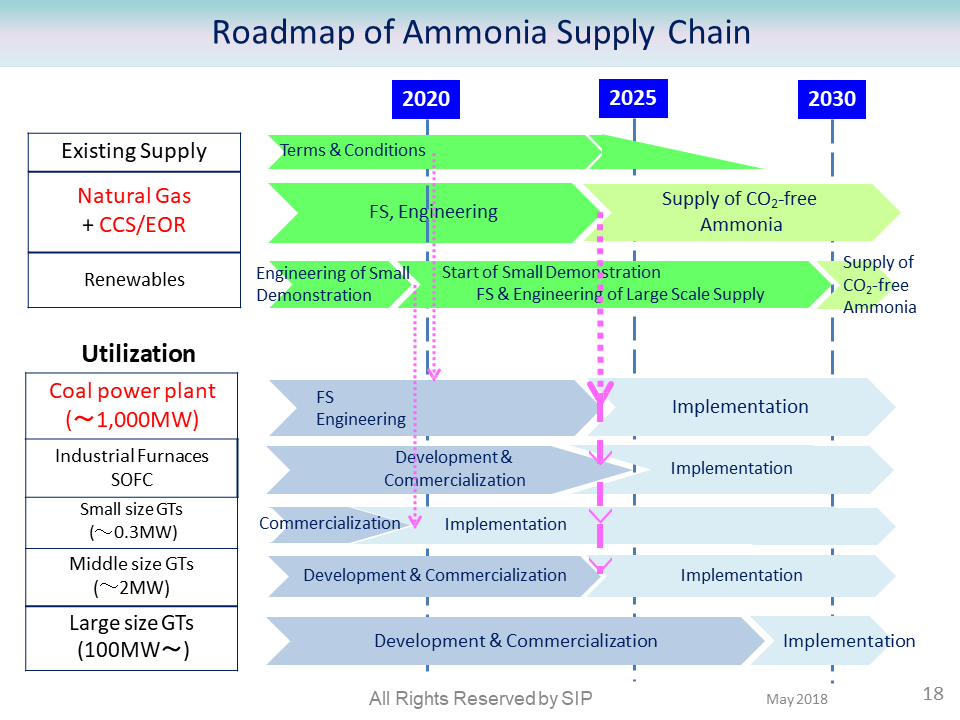

Muraki presented the “Roadmap of Ammonia Supply Chain” that illustrates this bridge, from ammonia produced from natural gas + CCS, to ammonia produced from renewables.

In this roadmap, both the import volumes and the timeline are striking. These are not merely conceptual targets, but were signed into law by Prime Minister Abe in December 2017 in Japan’s Hydrogen Basic Strategy.

Imports of low-carbon ammonia are set to begin in 2024, produced from natural gas with carbon sequestration. Already completed today, however, is the “Small Demonstration” of carbon-free ammonia produced from renewables, which began operations in April 2018 at FREA in Fukushima Prefecture. The roadmap calls for a 10-year period devoted to further small demonstrations as well as feasibility studies (FS) and engineering of plants for the “Large Scale Supply” of renewable ammonia. Imports of truly carbon-free ammonia are anticipated to begin just 12 years from today, in 2030.

The lower half of the roadmap describes the schedule for consumption of this low-carbon and carbon-free ammonia in the power generation sector. This begins with small (~0.3 MW) gas turbines, which are already ready for commercial deployment. Larger scale utilization in coal-fired power plants (~1,000 MW) is set to begin in 2024.

The full set of slides illustrating Muraki’s keynote speech is available to download from the Ammonia Energy Association’s web page for the 2018 NH3 Energy Implementation Conference. It contains a detailed list of Key Achievements of the SIP Energy Carriers program’s R&D projects, almost all of which have been reported here over the last two years. And it concludes with the introduction of the Green Ammonia Consortium, a subject to which we will return shortly.

In the meantime, here is the video that Muraki discussed, showing the successful 2017 demonstration of ammonia combustion in the 155 MW Mizushima Power Station operated by Chugoku Electric.