Duiker Clean Technologies: FID reached for pilot ammonia cracking facility

By Julian Atchison on May 19, 2025

Funds secured from the Netherlands Enterprise Agency and EU

Click to learn more. Graphic visualization of the pilot ammonia cracking plant. Source: Duiker Clean Technologies.

Duiker Clean Technologies will construct and operate an industrial-scale pilot plant for its ammonia cracking technology in the Netherlands, thanks to government and EU funding. The Netherlands Enterprise Agency (RVO) is supporting the project under the DEI+ scheme, with co-financing from the EU via the Just Transition Fund (JTF). Construction is underway, and Duiker expects to complete testing by 2027.

The pilot plant has a clear technical purpose. It will validate the performance, thermal efficiency and reliability of Duiker’s Ammonia Cracking technology at industrial scale. For engineers, this means access to real-world performance data and operational benchmarks. For investors, it offers proof of technology readiness, low total cost of ownership and strong scalability potential. In practice, applications range from hydrogen supply chains to industrial heating and energy import terminals.

From Duiker’s official press release, 14 May 2025

Based on Duiker’s low-emission cracking technology

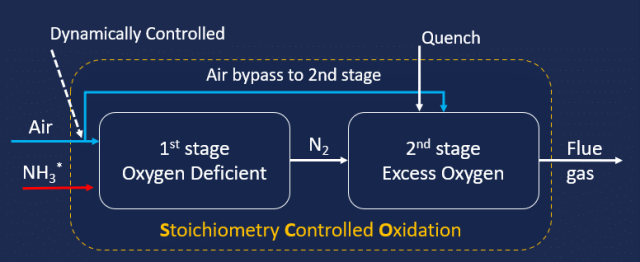

Click to enlarge. Duiker’s SCO (Stoichiometric Controlled Oxidation) ammonia combustion system. Source: Duiker Clean Technologies.

The pilot plant will be based on two pieces of Duiker technology: a cracking reactor with proprietary catalyst, and Duiker’s SCO (Stoichiometric Controlled Oxidation) ammonia combustion system. The SCO system features two-stage ammonia combustion with dynamic controls, minimizing NOX emissions. The SCO system will produce heat for the cracking reactor and pressure swing adsorption (PSA) unit, which removes impurities from the outgoing hydrogen stream, producing high-quality hydrogen.