FertigHy: reducing dependence on fossil-based fertilizers in Europe

By Kevin Rouwenhorst on March 16, 2025

In our March episode of Project Features, José Antonio de las Heras from FertigHy and David Franz from Stamicarbon discussed the low-carbon fertilizer production in Europe, based on water electrolysis. FertigHy aims to build, own, and operate low-carbon fertilizer plants, starting with its first facility in northern France. The recording is available on the AEA’s website, and you can also download the speaker presentations.

Decarbonization options in Europe

Currently, Europe has around 17.7 million tons of ammonia production capacity, some of which is not currently operational due to high gas prices in Europe.

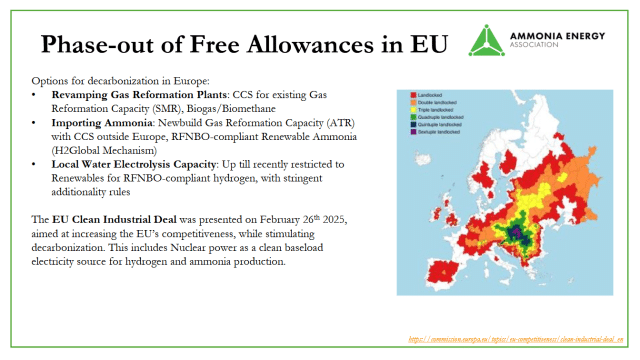

Click to expand. Phase-out of free emission allowance for the EU ammonia production industry. From Kevin Rouwenhorst, March 2025 Project Features introduction.

The European Union will soon see the phase out of free emission allowances in the ammonia industry, above which companies have to buy CO2 emission certificates within the Emission Trading System (ETS). Currently, this free allowance emission benchmark is 1.570 ton CO2 per ton ammonia. Free allowances for the ammonia industry will be phased down to zero tons CO2 per ton ammonia produced by 2034.

Faced with this challenge, there are various options to decarbonize the European ammonia industry. Firstly, existing European ammonia plants based on steam methane reforming for hydrogen can be revamped with CCS. From this year, 800,000 tons of CO2 captured from Yara’s Sluiskil site in the Netherlands will be transported to Norway every year, for permanent underground CO2 storage. However, CCS is only effective for about two thirds of the CO2 footprint in an ammonia plant, as carbon capture of CO2 from the burners in steam methane reforming can be very costly. Alternatively, biogas or biomethane can be blended in small quantities into steam methane reformers of existing ammonia plants, which is done by BASF in Germany, and OCI in the Netherlands.

Secondly, low-emission ammonia can be imported from outside of Europe. This will be ammonia produced with hydrogen produced via autothermal reforming with full CCS in regions with low cost gas, or ammonia produced with hydrogen produced via water electrolysis in regions with the best renewable energy potential. As shown above, imports may be a cost-effective option for coastal fertilizer complexes in the EU, but less so for inland plants.

Thirdly, ammonia plants fed by hydrogen produced via water electrolysis are being considered within Europe. Operating examples include partial revamps of existing ammonia plants, such as the 20 MW PEM electrolysis system supplying hydrogen to Fertiberia in Spain (an additional 50 MW system is planned), and the 24 MW PEM electrolysis system supplying hydrogen to Yara in Norway. Newbuild ammonia plants and fertilizer complexes with hydrogen production via water electrolysis are also proposed, to reduce dependency on imports.

Up till recently, the focus for water electrolysis was on RFNBO-compliant hydrogen based on renewables such as solar and wind. In February 2025, the EU Clean Industrial Deal was announced, aimed at increasing the EU’s industrial competitiveness, while stimulating decarbonization. This plan includes nuclear power as a clean baseload electricity source for hydrogen and ammonia production. Especially for landlocked plants without easy access to imports (and without the best renewable potential) grid-based nuclear power can potentially play a role in decarbonizing ammonia production.

FertigHy: grid-connected, baseload operations

FertigHy was established in June 2023 by a consortium along the fertilizer value chain, including founding investors EIT InnoEnergy, RIC Energy, Maire, Siemens Financial Services, InVivo and Heineken. Leveraging the value chain approach is key for ensuring credible consortia partners for financing, as well as for a portion of the fertilizer offtake.

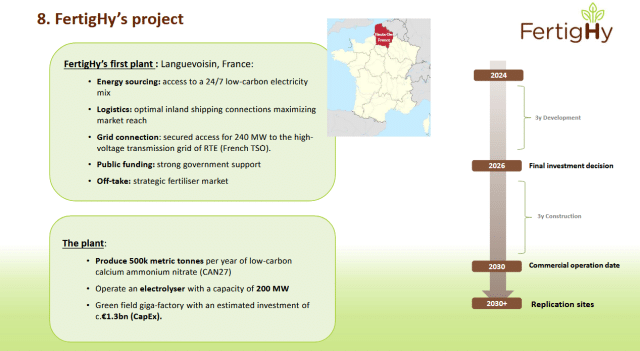

Click to expand. The FertigHy Project in Northern France. From José Antonio de las Heras, Low carbon fertilisers to decarbonise the food value chain (Mar 2025).

The first plant in northern France is scheduled to start construction in 2027 and is set to produce 500,000 tons per year of low-carbon nitrogen-based fertilizers (CAN27, calcium ammonium nitrate)from 2030 onward, using ammonia produced from electrolytic hydrogen. 200 MW electrolyzer capacity will be installed onsite, and the ammonia production is around 170,000 tons per year. The plant will operate in a “baseload” mode with a connection to the grid, tapping into the renewable and nuclear power-dominated electricity grid in northern France. This allows for a high utilization rate of the electrolyzers with clean electricity, while minimizing the need for batteries and hydrogen storage facilities.

A newbuild complex has various benefits versus revamping an existing complex, namely (1) not having workers idle during extended shutdown for revamping, and (2) building according to the latest environmental regulation standards, such as minimization of N2O and NOX emissions from the facility, and dust capture from ammonium nitrate granulation.

The total investment of the fertilizer complex is estimated at around €1.3 billion (excluding the electricity supply). Assuming a long-term PPA (power purchase agreement), a long-term fixed price can be offered for the low-carbon fertilizers, thereby limiting price volatility. Also, security of supply and sovereignty are key criteria for low-emission European fertilizer production.

The cost of fertilizers in a final product is typically below 1%, while the greenhouse gas (GHG) emissions from fertilizer production can account for 5-15% of the total GHG emissions associated with the product. This makes low-emission fertilizers an early, impactful target for food companies to achieve their targets for scope 3 emission reductions.

The FertigHy concept in northern France can be replicated to other European countries, and outside Europe. The concept can be replicated to other regions, assuming the grid is decarbonized, as this allows for baseload operation.

Stamicarbon: considerations for a technology licensor

Stamicarbon is the nitrogen technology licensor of NEXTCHEM, which is part of the industrial conglomerate MAIRE Group. Stamicarbon designs and licenses fertilizer plant technologies, specializing in urea production, ammonia production, and nitric acid production. In total, over 300 licenses have been issued worldwide, mostly in urea production. Through its sister company NEXTCHEM, Stamicarbon can also integrate pressurized autothermal reforming and water electrolysis technologies.

Stamicarbon has performed various feasibility studies and pre-FEEDs for renewable ammonia plants. Stamicarbon has also signed the license for a 450 tons per day ammonia loop for the Meadowlark project of JWC Gburg in Nebraska, USA. Stamicarbon through its NX Stami AmmoniaTM offers proven design of ammonia synthesis loop for various plant concepts. Designs are optimized to match the needs of innovative plant configurations with different requirements. Traditional grey projects can be paired with high-performing steam methane reformer (SMR) and/or autothermal reformer (ATR) technologies from GasContec (which is another sister company in MAIRE Group).

Low-carbon or blue projects with smaller capacities for local utilization utilize either a high or medium pressure design emphasizing high conversion or low OPEX in combination with a catalytic partial oxidation (CPO) process. Green projects are optimized either in high-pressure (300 bar pressure) or medium pressure (160 bar pressure) format, with an emphasis on low-CAPEX and OPEX, small footprint and flexible operational parameters (e.g. turn-down) to adapt to the more sensitive economic dynamics of these projects.

Some of the key aspects encountered in renewable ammonia projects like FertigHy include: (1) the most efficient technology combination is key, (2) innovative business models are required including secure electricity supply and offtake, and (3) a supportive environment from a regulatory side is required.

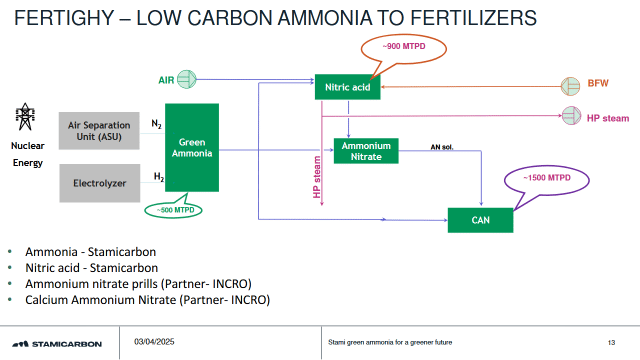

Click to expand. FertigHy process overview. From David Franz, Stamicarbon – FertigHy (Mar 2025).

The FertigHy consortium has awarded a feasibility study and pre-FEED contract to Stamicarbon for a new renewable ammonia and fertilizer plant. As part of the agreement, Stamicarbon will provide its NX Stami AmmoniaTM and NX Stami Nitric AcidTM technologies for the project. The pre-FEED engineering is currently finalizing, and FEED engineering is proposed to start later in 2025.

Designing an integrated fertilizer complex rather than a separate ammonia project allows for optimizing the overall energy consumption of the plant, as exothermic processes (those releasing heat) can be heat integrated with endothermic processes (those requiring heat). Heat in the form of steam from the nitric acid plant can be used for the ammonium nitrate plant and the calcium ammonium nitrate granulation plant, while heat integration with the hydrogen production or ammonia production plant may also be possible.