Hydro-electric ammonia: project design, engineering & technology selection

By Kevin Rouwenhorst on May 15, 2023

In our April episode of Ammonia Project Features, Olivier Mussat (ATOME), Santiago Del Valle (URBAS) and Ermanno Filippi (Casale) discussed the Villeta project for renewable ammonia production from surplus hydroelectricity in Paraguay. The recording is available on the AEA’s Vimeo channel, and you can download the speaker presentations.

Most renewable ammonia plant announcements bank on new build solar PV and/or wind turbines for electricity generation. These renewables typically have a lower levelized cost and a shorter construction time than hydropower. However, hydropower is a more predictable, baseload source of electricity, and becomes especially competitive when existing surplus capacity is available. Historically, essentially all renewable ammonia plants with electrolysis-based hydrogen production were fed with hydroelectricity.

ATOME: the Villeta project, Paraguay

ATOME is a UK-based renewable hydrogen and ammonia project developer, with a current pipeline of 621 MW of projects globally. Its strategy is to deliver hydrogen and ammonia to current markets such as agriculture and heavy industry, so that progress for realization can be fast-tracked.

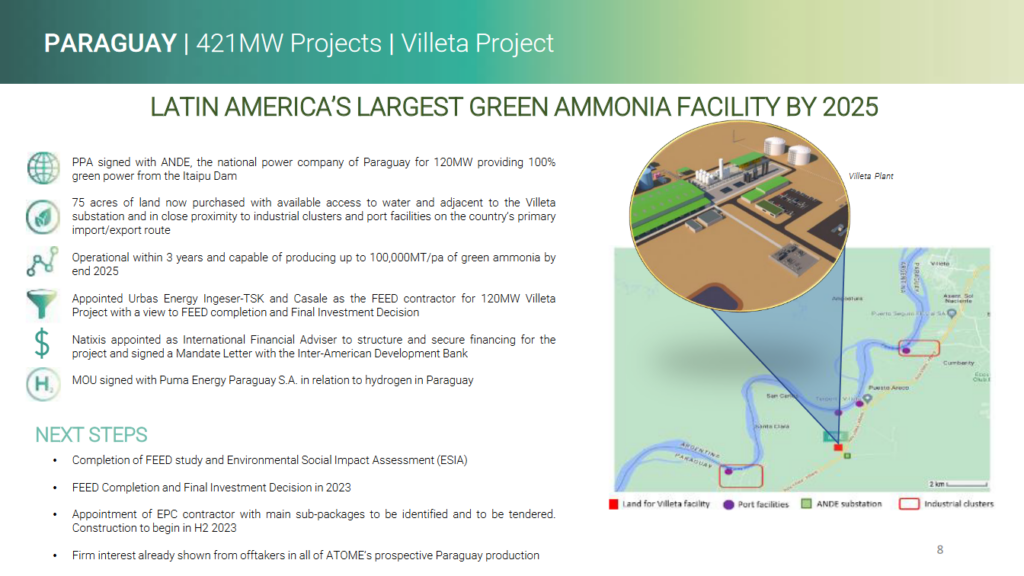

One of their first projects is the 120 MW Villeta project in Paraguay, which aims to use an existing surplus of hydroelectricity from the Itaipu dam, located at the border of Brazil and Paraguay. Currently, URBAS and Casale are doing a FEED (Front End Engineering Design) study for the Villeta project, which is on track for completion in Q2 2023. Upon reaching FID, the plant will start operation in 2025, reaching an annual production of up to 100,000 tonnes of ammonia per annum by 2026.

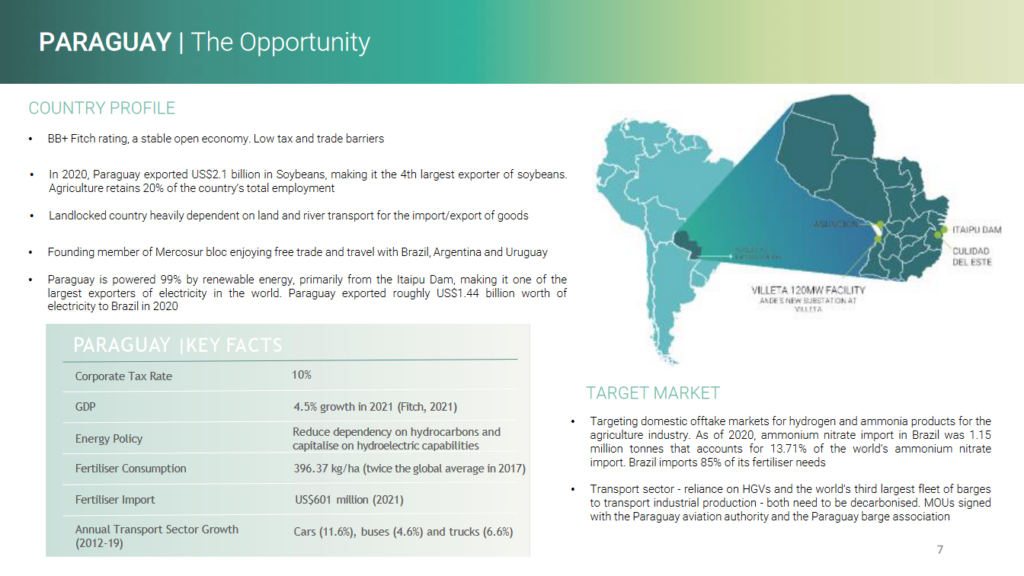

The Itaipu dam has a capacity for generating 14 GW, equally owned between Brazil (7 GW) and Paraguay (7 GW). Paraguay only uses about 3 GW out of its 7 GW, however, and currently sells its surplus electricity to Brazil. Electricity exports currently represent the largest export market for Paraguay, the second largest being agricultural production. The region is also a major importer of nitrogen fertilizers. According to ATOME, 601 million USD worth of fertilizers was imported to Paraguay in 2021 alone.

Within the Villeta project, about 120 MW of Paraguay’s surplus hydroelectricity will be redirected to produce up to 100,000 tonnes of ammonia per annum, replacing part of the nitrogen fertilizer import. The Villeta project will have an existing agricultural market nearby, limiting the supply chain challenge faced by export-based projects. The port of Villeta (south of Asuncion, Paraguay’s capital city), is located at the crossroads of the Parana and Paraguay rivers, and is the place where fertilizers are currently imported and agricultural products exported. Thus, it is already a location with industrial activities, decreasing challenges regarding environmental and social issues.

ATOME takes an infrastructure approach to developing projects. This minimizes risks and the number of challenges faced in the initial projects, and assures offtake in current markets. ATOME has selected a site close to the source of power, near potential offtakers and with access to a steady supply of water for electrolysis, ensuring associated costs to the ammonia plant are minimized (and enabling a fast track development schedule). Renewables development is not foreseen in the first phase of the Villeta project.

Instead, ATOME has signed a PPA (power purchase agreement) for 120 MW of hydroelectricity with ANDE, Paraguay’s state electricity and power distribution company. The hydroelectricity will be supplied at constant load, implying no flexibility in the electrolyzers, the air separation unit, and the Haber-Bosch plant. In this way, flexibility challenges such as for solar PV and/or wind projects are not faced in the Villeta project. Furthermore, the baseload plant can use alkaline electrolysis technology, which is the most established and has the lowest cost among electrolyzer technologies. The next phase of the project will see ATOME leverage a further 300 MW of surplus hydroelectricity from Paraguay’s grid, targeting production in 2027 for the plant (if a PPA is signed in 2023).

Coupling renewables with ammonia production: the engineering challenge

Essentially, ammonia production with electrolysis-based hydrogen production is about bringing together the world of electrons and molecules. URBAS Energy is a Spanish engineering and EPC firm, with various projects delivered in Latin America. URBAS will leverage its extensive expertise in the renewable electricity generation within the Villeta project.

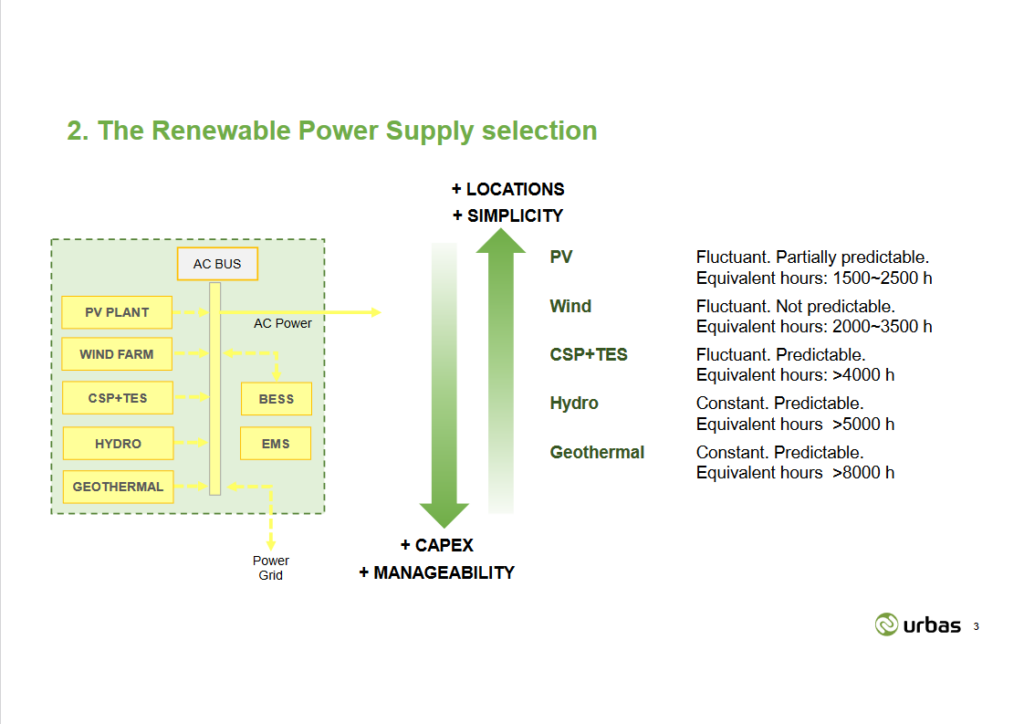

The Villeta project is based on hydroelectric power with a continuous availability. However, other projects may have a lower electricity capacity factor (solar PV and wind), as well as a lower predictability (especially wind). Depending on the source of electricity, electricity storage or a grid connection may be required to account for intermittency of renewables. Solar PV and wind have the lowest installation duration. Furthermore, solar PV and wind are often combined to increase the electrolyzer load factor to above 50%.

Other solutions, such as hydroelectricity and geothermal power have a higher predictability. However, the investment cost for this power is typically higher than solar PV and wind installation. Furthermore, the deployment of hydroelectricity and geothermal power is geographically limited.

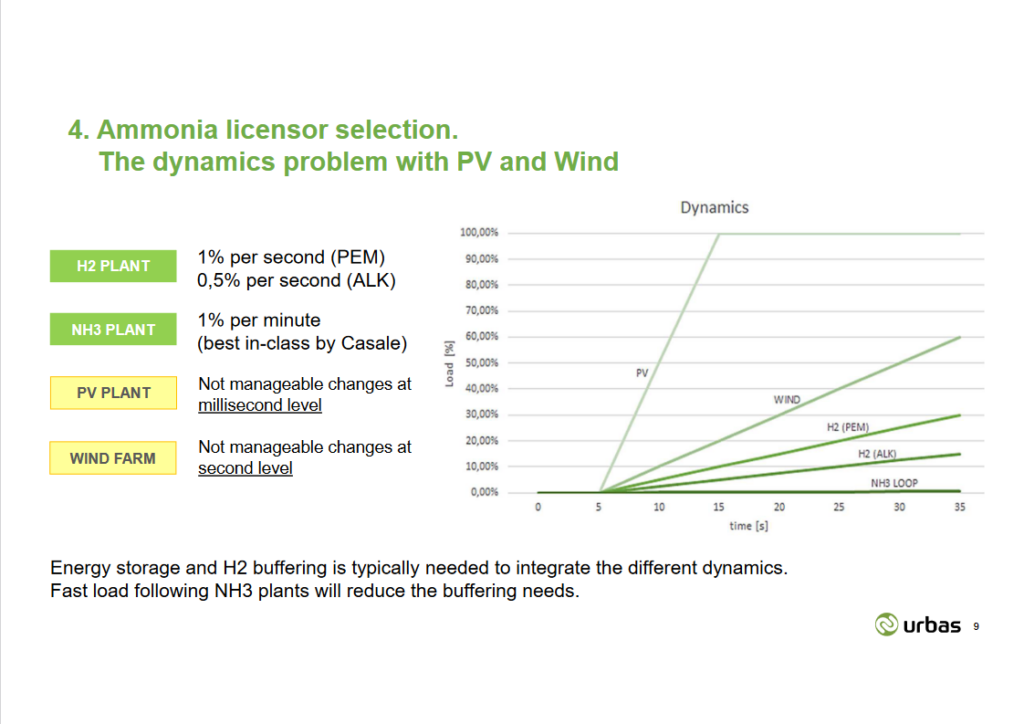

Most renewable ammonia projects being discussed rely on intermittent solar PV and wind. Dynamic operation of renewables, hydrogen production and ammonia production must be matched accordingly. Solar PV can change on a millisecond level, whereas wind can change on a second level. Newer electrolyzer technologies are relatively flexible, as estimated by URBAS at 1% and 0.5% load change per second for PEM electrolysis and alkaline electrolysis, respectively.

But, the ammonia loop can only change its load by about 1% per minute. Thus, adequate buffers are required, such as batteries and pressurized hydrogen storage. Storage buffers are relatively expensive, however, and their size can be minimized by operating flexible ammonia loops. Batteries and pressurized hydrogen storage cannot be eliminated completely, as HAZOP safety studies identify the need for emergency electricity and hydrogen supply to the ammonia loop for safe shutdown of the plant.

Casale: technologies to enable flexible production

Casale was the first ammonia licensor for a renewable ammonia plant. In 1921, Casale’s electrolyzer technology and ammonia synthesis technology was used to produce about 2 tonnes of ammonia per day in Nera Montoro, Italy. While Casale no longer produces electrolyzers, it has remained a licensor for syngas generation, methanol synthesis, ammonia synthesis, and ammonia derivatives.

Over the past century, various improvements have been made in Casale’s ammonia synthesis technology. The availability of larger compressors has allowed for the scale-up of the process, with the largest technology on offer from Casale being 6,000 tonnes of ammonia per day. Furthermore, Casale’s proprietary axial radial converter is among the most efficient ammonia converters available in industry, with a high single pass ammonia conversion and a high mechanical reliability. The axial radial converter has over 300 references worldwide, including revamps of existing ammonia plants from other licensors.

Recently, the performance of the axial radial converter was further improved with the development of the catalyst AmmoMax Casale, a development in cooperation with catalyst manufacturers Clariant. The iron-based catalyst is more active than other iron-based catalysts at low temperatures, and is more resistant to oxygenates, making it suitable for electrolysis-based hydrogen feedstocks.

Fossil-based ammonia plants and grid-connected, hydropower-based ammonia plants are essentially the same technology. The main difference is that electrolysers and an air separation unit generate pure hydrogen and nitrogen, as opposed to steam methane reforming where inert entities such as methane and argon end up in the ammonia loop. A similar pure hydrogen and nitrogen stream is also obtained for coal gasification-based ammonia plants, which has over 70 Casale references.

Next to grid-connected projects, Casale is involved in flexible ammonia production projects based on solar PV and/or wind. The intermittency of solar PV and wind requires the ammonia plant to be flexible, which implies adequate mechanical design of equipment is required for frequent flexible operation. Furthermore, the start-up heater needs to be designed for frequent operation, which was not the case for stable, fossil-based ammonia production. If designed adequately, the converter can operate at loads down to 5-10% nominal load.