IHI, NYK Line report successful marine engine testing in Japan

By Julian Atchison on May 23, 2023

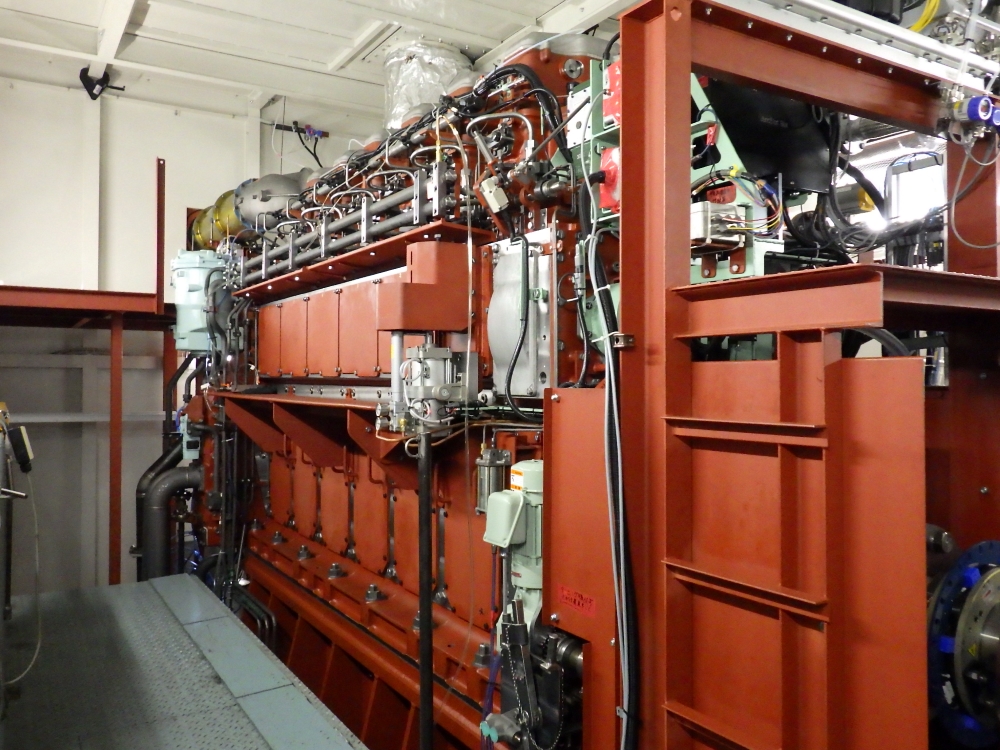

Four-stroke marine engine, 80% ammonia fuel mix

Together with Nihon Shipyard, Japan Engine Corporation and ClassNK, the pair have announced successful testing has been completed at IHI’s facilities in Ota, Japan. From April this year a 280mm bore, four-stroke marine engine has been put through its paces. A fully integrated setup – including exhaust gas aftertreatment technology and fuel supply systems – produced stable operations running on up to 80% ammonia fuel. Emissions of dinitrogen monoxide (N2O) and ammonia slip were reported as “virtually zero”, with no ammonia leakage from the equipment during operation and after shutdown.

The four-stroke test engine is representative of typical main engines seen in coastal vessels & port craft. Indeed, the first application for this engine after testing will be on-board the A-Tug – an ammonia-powered tugboat under development in Yokohama. The tugboat is expected to be delivered to the Port of Yokohama in June 2024.

This new research will also inform a related, ocean-going venture. The same group is developing an ammonia-fueled ammonia gas carrier (AFAGC), with a two-stroke main engine to run on at least 95% ammonia fuel. Based on this test engine in Ota, a 250 mm bore, four-stroke auxiliary engine will be developed for the AFAGC, further reducing the on-board use of conventional maritime fuels. That vessel is expected to be delivered in 2026.

Engine room safety

In our recent episode of Maritime Ammonia Insights, Wärtsilä representatives shared some of their own experiences testing four-stroke marine engines (adapted from existing dual-fuel engines, and operating with a small amount of conventional pilot fuel). During testing in Finland, ammonia slip was detected at low levels in the engine exhaust, but no aftertreatment systems were employed, and addition of a catalytic converter would eliminate these emissions (as well as NOx). Residual ammonia was detected in the engine case (10ppm, 24 hours after operation) & lubricating oil (100ppm, no loss of function), with investigations to continue. It was noted that treating the engine room as a “gas safe space” – a safety approach employed with current dual fuel engines – is highly beneficial when designing and engineering a safe working space containing an ammonia-powered engine.