Japan Advances SOFCs for the Built Environment

By Stephen H. Crolius on March 05, 2020

A steady stream of Japanese news reports over the last several months attest to the country’s progress in deploying fuel cells in the built environment. Dubbed “Ene-Farms,” the appliances function as micro-scale combined heat and power units, providing electricity as well as heat for domestic applications. Most of the Ene-Farms deployed so far feature proton-exchange membrane (PEM) technology (which requires high-purity hydrogen). However, two recent developments show that solid oxide fuel cell (SOFC) technology (well suited for ammonia) could play a role, maybe even a large role, in Japan’s Hydrogen Society.

Morimura SOFC Technology Company

First up is the appearance of a new Japanese SOFC producer. In September 2019, ceramics producer Morimura Group announced that four Group companies were collaborating to form Morimura SOFC Technology Company. (One of the companies, Toto, had previously been identified as a partner in an effort to develop a novel hydrogen synthesis technology.) In a February 8, 2020 Nikkei interview (“Fuel cells for households in FY2025. Interview with Morimura’s new company president”), Morimura SOFC President Yoshikuni Sato stated that the company will cross the commercialization threshold this year. “We will ship products for commercial facilities in FY2020 as planned,” he said. “We will build up our track record for business use, and enter the home market in FY2025.”

As with other Ene-Farm fuel cells, the apparent fuel for the Morimura units is natural gas. It is not clear if the company has knowledge of or interest in ammonia as an alternative SOFC fuel.

Kyoto University – IHI Research Group

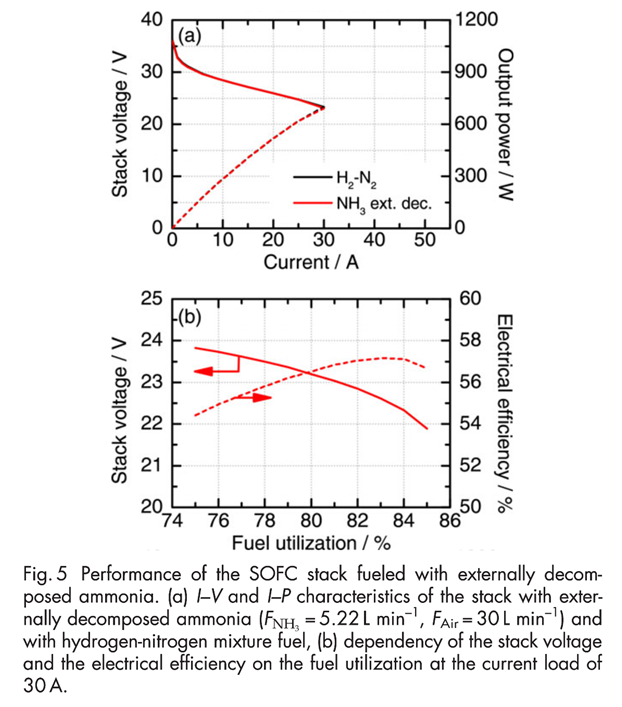

The second development is the January 2020 publication of “Development of 1 kW-class Ammonia Fueled Solid Oxide Fuel Cell Stack” in the research journal Fuel Cells. The paper describes work done by a multi-partner research group whose members include Kyoto University, IHI Corporation, Noritake, Nippon Shokubai, Toyota Industries, and Mitsui Chemicals.

A May 2018 Ammonia Energy article on the origins of the SOFC effort at Kyoto University and the subsequent coalescing of the research group quoted a recent Nikkei Sangyo report that “the power generation efficiency [of the IHI-Kyoto University SOFC] aims at the latter half of the 40% level which is comparable to that of residential fuel cells already in practical use.” In its Fuel Cells paper, the research group summarized the state of its technology before the start of its current research campaign as follows:

An SOFC stack fueled with the direct ammonia supply was successfully operated with an electrical output of ca. 200 W for 1,000 h at 770 °C. However, the electrical output of the short stack was still insufficient and further scale-up is required to provide more practical insights for realization of the ammonia-fueled SOFC systems. Also, the energy conversion efficiency was no more than 40% because of the lower fuel utilization around 60%.

Kishimoto, M., et al., “Development of 1 kW-class Ammonia Fueled Solid Oxide Fuel Cell Stack,” Fuel Cells 20, 2020, No. 1, 80–88

The group’s current research campaign focused on alternative modes of ammonia processing, with direct ammonia supply being compared with two types of ammonia pre-cracking (“external decomposition” and “autothermal decomposition”). The group developed a “novel catalyst for the external ammonia decomposition … to achieve higher catalytic activity and hence scalability, and its durability [was] tested for 1,000 h. In addition, [overall] stability of the ammonia-fueled SOFC stacks was evaluated for 1,000 h.”

The reported results are striking. Fuel utilization was increased for all three modes to more than 80%. In addition, “DC electrical efficiency” was achieved in the 55-60% range, with direct ammonia logging “690 W power output with 55.9% efficiency,” and external decomposition doing even better: “705 W with 57.3% efficiency.” (The disadvantage for direct ammonia is attributed to the “decrease in the stack temperature caused by the endothermic ammonia decomposition reaction.”)

While the group also found that its novel catalysts exhibited satisfactory durability over 1,000 hours of service, a degradation effect of the separator materials was observed with direct ammonia supply that “is liable to alter the fuel flow within the stack and thereby degrade the stack performance in much longer time scale.” This effect was not observed with the external decomposition approach. The group concludes, “therefore, the utilization of the external ammonia cracker is considered as a possible choice to operate SOFC stacks to avoid such adverse influence of the ammonia fuel on the stack materials.”

Long-Term Fuel Supply Plan

Conspicuous by its absence in the general Ene-Farm reporting is discussion of long-term options for retail fuel supply. Hydrogen distribution via the natural gas network may be the first idea to spring to mind, but, according to a 2016 paper by Yoshiaki Shibata, Senior Economist at the Institute of Energy Economics, Japan, the country’s “poorly developed natural gas pipeline network hinders working with the power grid and hydrogen.” A green version of “substitute natural gas” (SNG) – consisting of renewably produced hydrogen combined with carbon dioxide from direct air capture to produce green methane – could be used to displace fossil methane. However, Shibata believes that even “SNG blending [would be] considerably difficult” and that “new infrastructure [would need to be] constructed either for hydrogen or SNG in Japan.”

The Kyoto University-IHI group points to ammonia as a potential alternative: “Chemical compounds containing hydrogen, such as hydrocarbons [including SNG], alcohols and ammonia, can be used as hydrogen carriers to transport and store hydrogen. In most cases there are already well-established infrastructures in our society to safely and effectively handle these hydrogen compounds. Among the hydrogen carriers, ammonia has been attracting great attention,” based substantially on its advantageous physical characteristics.

But while Morimura’s Sato points to the Japanese government’s steadfast commitment to the deployment of 5.3 million residential Ene-Farms by 2030, how those units will be supplied with fuel, or even what fuel they will be supplied with, remains unclear.

Addendum March 26, 2020. On January 29, 2020, Morimura Group member NGK Spark Plug Company announced that it had established Cecylls Company as a joint venture with thermal power systems manufacturer Mitsubishi Hitachi Power Systems, Ltd. According to a Yahoo Finance story, the new company will manufacture and sell cylindrical cell stacks as the power generating elements used in solid oxide fuel cells.