MAN Energy Solutions: an ammonia engine for the maritime sector

By Trevor Brown on January 25, 2019

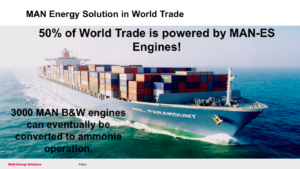

In June 2018, MAN Diesel & Turbo rebranded itself MAN Energy Solutions, reflecting the maritime engine market leader’s “strategic and technological transformation” towards sustainability. The company was “taking a stand for the Paris Climate Agreement and the global pursuit of a carbon-neutral economy.” According to Uwe Lauber, Chairman of the Board, “our activities have a significant impact on the global economy. In shipping, for example, we move more than half of the global stream of goods … [and] the path to decarbonising the maritime economy starts with fuel decarbonisation, especially in container shipping.”

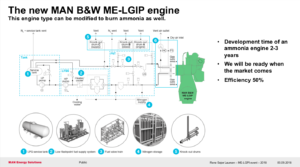

This week, the company took a significant step towards realizing its vision, disclosing that it is “pressing ahead with developing … an ammonia-fuelled engine.” This builds on the technology development pathway that MAN ES presented at the NH3 Energy+ Topical Conference at Pittsburgh in October 2018. The budget and timeline are set: the €5 million (USD$5.7 million) project will last two to three years and, if the shipowners decide to deploy the finished product, “the first ammonia engine could then be in operation by early 2022.”

Perhaps as important as the technology development, MAN ES is also supporting the implementation of ammonia as a fuel through industry partnerships, financing, and regulations. The company is busy with a safety study “in cooperation with class, a yard, a manufacturer of fuel gas supply systems and a shipowner.” It is also part of a yet-to-be-announced consortium, including “big-name company business partners and universities,” created to attract funding “for the development of ammonia engines.” And it intends to get ammonia accepted as a fuel in the IGC Code, by getting “approval from a flag state — likely Norway — to use ammonia as a marine fuel,” which it expects “to be completed before this summer.”

MAN Energy Solution’s ammonia engine will be based on the MAN B&W Dual Fuel ME-LGIP Engines, which use liquefied petroleum gas (LPG) as a low-emission fuel, allowing shipowners to be compliant with the 2020 sulphur emissions cap. Both Exmar and Statoil (now Equinor) have placed orders for this engine.

From the perspective of introducing ammonia as a maritime fuel, there are two advantages to using an engine designed for dual fuel use. First, it provides confidence in fuel availability during a transition period when infrastructure is still under expansion: if ammonia is not yet bunkered at any particular port, the ship operator can use an alternative fuel. Second, it allows swifter decarbonization of the existing maritime fleet, because retrofits are possible: according to René Laursen’s presentation at the NH3 Energy+ Topical Conference, “3000 MAN B&W engines can eventually be converted to ammonia operation.”

Laursen’s presentation began with a history lesson to remind everyone that bunkering infrastructure is not a prerequisite for commercial voyages. In the early 20th Century, the industry still used coal as its fuel, before its transition to oil. “In 1912 the Diesel driven MV Selandia left Copenhagen into a world with no fuel bunkering possibilities.” Of course, it did so using a “1050 HP B&W engine” [Burmeister & Wain, now MAN ES].

In the quest to find zero-carbon solutions to meet the IMO’s 2050 emissions targets … ammonia is being considered as a potential source of marine bunkers.

There are already some 170 ships in operation that can carry ammonia, with around 40 of these continually carrying the product, so proponents argue that it would be relatively simple to upscale the existing infrastructure to provide it as marine bunkers.

Ammonia can be burnt in an engine without producing any CO2 or carbon and may be stored either as a liquid at -34C or at normal temperatures under around 10 bar pressure …

MAN Energy Solutions is kicking off the development of an ammonia-fuelled engine on the back of the interest that the company says it has received from several shipowners.

TradeWinds News, Ammonia swings into frame as a potential future marine fuel, 01/22/2019

With ammonia, safety is paramount. While an advantage of using ammonia as a fuel is that it is not explosive, a disadvantage is that it is toxic, and “it is the toxicity and hazardous nature of the product that shipping industry players frequently highlight as their key concern.”

For regulations, the International Code of the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (the IGC Code) “prohibits the use of toxic products as fuel.” However, this code can be amended if a flag state accepts the new fuel and proposes changes.

Moving bunker ammonia forward through this complex regulatory path requires a coalition of stakeholders, including classification societies, ship builders, technology developers, shipowners, and flag states, which MAN ES is evidently coordinating.

Laursen explains that in the next six months the company will undertake a hazard identification (HAZID) study in cooperation with class, a yard, a manufacturer of fuel gas supply systems and a shipowner, which he declines to name.

After this, MAN intends to get approval from a flag state — likely Norway — to use ammonia as a marine fuel.

“We do not see this [approval] as a big problem as we have done it before with LPG, methanol, ethane gas and LNG,” he says. “Ammonia has been used as a refrigerant in an engine room for many years, so codes already exist on how to handle it even though it is toxic.”

… Laursen expects the flag state approval for ammonia to be completed before this summer.

TradeWinds News, Ammonia swings into frame as a potential future marine fuel, 01/22/2019

MAN ES has a full technical paper on its MAN B&W ME-LGIP dual-fuel engines, available to download from its website. Its new ambitions to develop an ammonia version of this engine are outlined in Laursen’s NH3 Energy+ Topical Conference presentation, available to download from the conference webpage, entitled Ship Operation Using LPG and Ammonia As Fuel on MAN B&W Dual Fuel ME-LGIP Engines.

The two-stroke engine design is suitable for large ocean-going vessels, including tankers, bulk carriers, and container ships, with “engine sizes from 5 to 85 MW.”

This paper describes the technology behind the ME-LGIP dual fuel MAN B&W two-stroke engines, using LPG as fuel, and its associated LPG tank and fuel supply systems … We have lately found that this engine technology, with minor modification, can also be used to burn ammonia, so the paper will also describe the modification needed in order to build an engine that is able to burn LPG as well as ammonia.

René Laursen, Ship Operation Using LPG and Ammonia As Fuel on MAN B&W Dual Fuel ME-LGIP Engines, NH3 Fuel Conference, October 2018

For decades, the argument for ammonia as a fuel has been stymied by the chicken-and-egg dilemma. Without demand, there was no product; and without the product, demand was invisible. This is changing. With the International Maritime Organization’s Initial GHG Strategy calling for a 50% reduction in maritime emissions by 2050, there is tremendous demand for a viable carbon-free fuel. Soon, with a commercially available ammonia engine, that dilemma will be history.