Maritime updates: modeling engine room fuel leaks, testing a new fuel supply system

By Julian Atchison on June 04, 2023

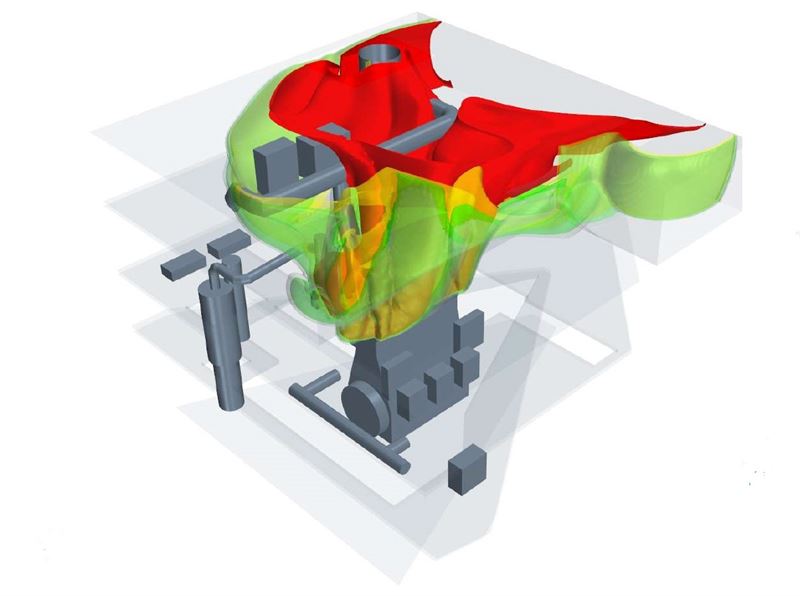

American Bureau of Shipping

ABS has utilised advanced modeling technology & computational fluid dynamics to replicate ammonia dispersion patterns in a ship’s engine room. The new modeling technique will assist the development of emergency response procedures to ammonia leaks or spills, and ABS aims to produce a fast, real-time response system “capable of predicting the behavior of an ammonia plume and directing emergency mitigation services accordingly”.

Our advanced simulation and modeling approach is already shining a light on the unique behaviors of this fuel in a range of scenarios. This will inform the strategies of ports, crews and emergency services and enable immediate and informed response to an ammonia release. This is the sweet spot for ABS, the nexus of advanced technology, regulation and safety and we are on course to deliver a significant safety development for the industry.

ABS CEO Christopher J. Wiernicki in his organisation’s official press release, 18 May 2023

The model has already been utilised by ABS to assess the impact of various ventilation approaches in an ammonia-fueled engine room. Ultimately, the final model will be able to predict the response of an ammonia leak to parameters such as wind speed & direction, humidity and the relationship of the vessel to port.

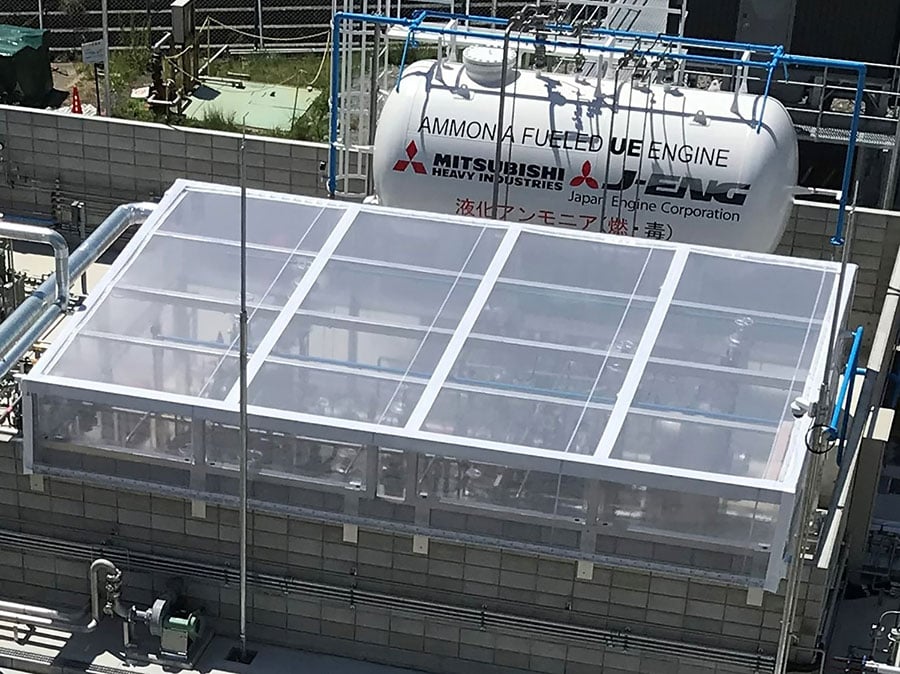

Final testing stages in Japan

Japan Engine Corporation is currently testing a fuel supply system for large-scale, low-speed, two-stroke marine engines at MHI’s R&D facilities in Nagasaki, Japan. Mitsubishi Shipbuilding built and delivered the test system, which is undergoing final verification testing before it can become commercially available. By acting as a key technology provider in the maritime ammonia fuel space, Mitsubishi Shipbuilding aims to expand its business and accelerate the decarbonisation of shipping in Japan and beyond.