New ammonia cracking systems under-development in Japan

By Julian Atchison on May 07, 2024

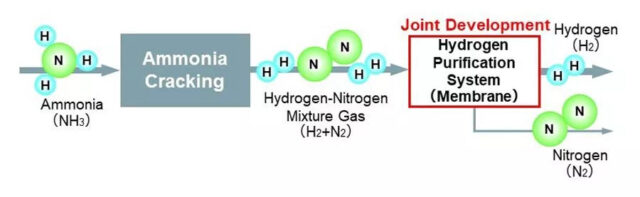

Membrane separation for high-purity hydrogen

Click to learn more. MHI and NGK will collaborate to develop a purification system to produce high-purity hydrogen from ammonia cracking. Source: Mitsubishi Heavy Industries.

Mitsubishi Heavy Industries and NGK Insulators will jointly develop a purification system that will produce high-purity hydrogen from ammonia cracking. NGK will contribute its expertise in water purification, where it has combined sub nano ceramic membrane technology and proprietary film deposition techniques to create high precision membranes. MHI will assist in scaling this technology to chemical plant-size, to the point where it will be able to play a role in a future hydrogen and ammonia supply chain in Japan.

Join our Project Features webinar on May 23 to learn more about H2SITE’s membrane-based purification technology, producing high-purity hydrogen from ammonia cracking.

Other organisations pursuing membrane-based purification combined with ammonia cracking include Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO), which demonstrated its technology in 2018 and continues to work towards commercialisation in partnership with Fortescue. Spain-based H2SITE has demonstrated its technology in the UK (vehicle refueling), and in the Gulf of Biscay (fuel cell powering an offshore supply vessel). H2SITE will join us for a Project Features webinar at the end of this month to further discuss the combination of ammonia cracking and membrane separation: register here to learn more.

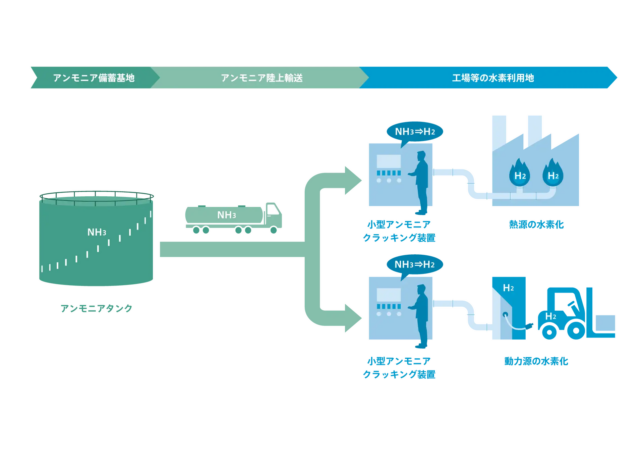

Toyo Engineering: small-scale cracking

Click to learn more. Toyo Engineering and Nippon Seisen will lead development of a small-scale ammonia cracking unit, producing on-demand hydrogen for vehicle fuel and power generation. Source: Toyo.

A group including Toyo Engineering, Nippon Seisen, Chubu Electric Power have signed an MoU to develop a small ammonia cracking unit to produce on-demand hydrogen for vehicle refueling and power generation fuel in Japan. In the announcement, Toyo and Nippon Seisen indicate they have “long been working” on small-scale ammonia cracking units that can operate on “customers’ premises”. Chubu Electric Power will lead a small group of organisation in conducting demonstrations of the unit, with the aim of creating a commercially-available product.