New modular hydrogen production technology unveiled by InterContinental Energy

By Geofrey Njovu on May 22, 2025

20% lower production costs

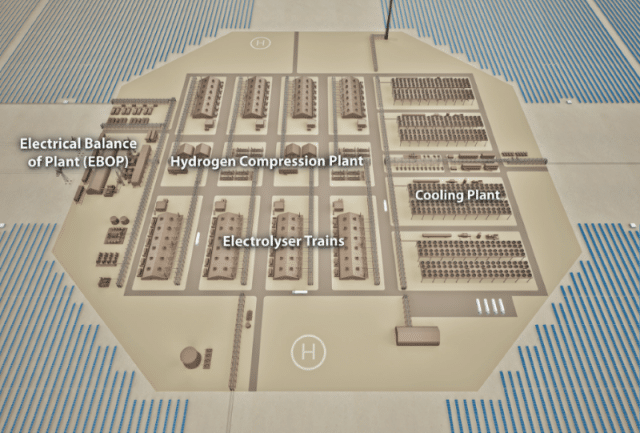

Click to enlarge. InterContinental’s P2(H2)Node system can lower CAPEX by 10%, improve efficiency by 10%, and could result in a 20% reduction in hydrogen production costs. Source: InterContinental Energy.

InterContinental Energy has announced its new, patented P2(H2)Node™ system, a modular hydrogen production model that colocates hydrogen production within wind and solar farms. The major advantage of the new power-to-hydrogen system is that its colocation with renewable energy sources eliminates expensive high-voltage power transmission equipment, which often leads to energy loss. The system also minimises electrical connections between renewable energy sources and hydrogen production.

According to the company press release, the standardised architecture of the P2(H2)Node system lowers production costs by about 10-20% (10% lower Capex and 10% higher efficiency) relative to conventional production models. In this design, renewable energy is stored mainly as hydrogen and delivered to customers via hydrogen pipelines that are more consistent.

InterContinental claims that the P2(H2)Node system will “streamline” hydrogen production “in the same way as standardised shipping containers revolutionised the global shipping industry”. Each node features 2GW of wind and solar energy and 1 GW of electrolysis capacity, with minimal (expensive and inefficient) electrical connection between the renewable energy and the hydrogen production unit.

InterContinental Energy, which owns the majority stake in the government-backed Western Green Energy Hub (WGEH), sees the P2(H2)Node system as a key player in that project. WGEH has a planned capacity of 70 GW of renewable energy for renewable hydrogen and ammonia production for the export market. Thanks to government incentives, hydrogen will be produced at the relatively low cost of US$650 per ton. Having received the nod from the Environmental Protection Authority, the project is now undergoing a public environmental review.

Beyond its own projects, InterContinental also intends to outsource the P2(H2)Node architecture to other developers for deployment in renewable hydrogen projects across the industry.

Learn more in Perth

InterContinental Energy’s Head of Australia Isaac Hinton (and some of the Perth-based team) will be at the upcoming APAC event June 16-18, and you can hear Isaac’s thoughts on the pathway to large-scale deployment for hydrogen in our conference wrap panel. Join us in a few weeks to hear insights from Intercontinental, and to network with their team of experts.

We are proud that our team in Perth has developed this globally significant technology. The P2(H2)Node architecture is a breakthrough in clean hydrogen production. By eliminating transmission losses and leveraging a modular approach, we are making green hydrogen cost-competitive at scale for the planet.

This technology comes at a time when Australia is poised to become a global leader in e-fuels and green iron.

Alexander Tancock, CEO at InterContinental Energy, in his organisation’s official press release, 13 May 2025