Safe ammonia bunkering at the Port of Roenne

By Sofia Furstenberg Stott on October 28, 2022

Watch a replay of the discussion via the AEA’s Vimeo channel.

Island of Bornholm: a future exporter of e-ammonia?

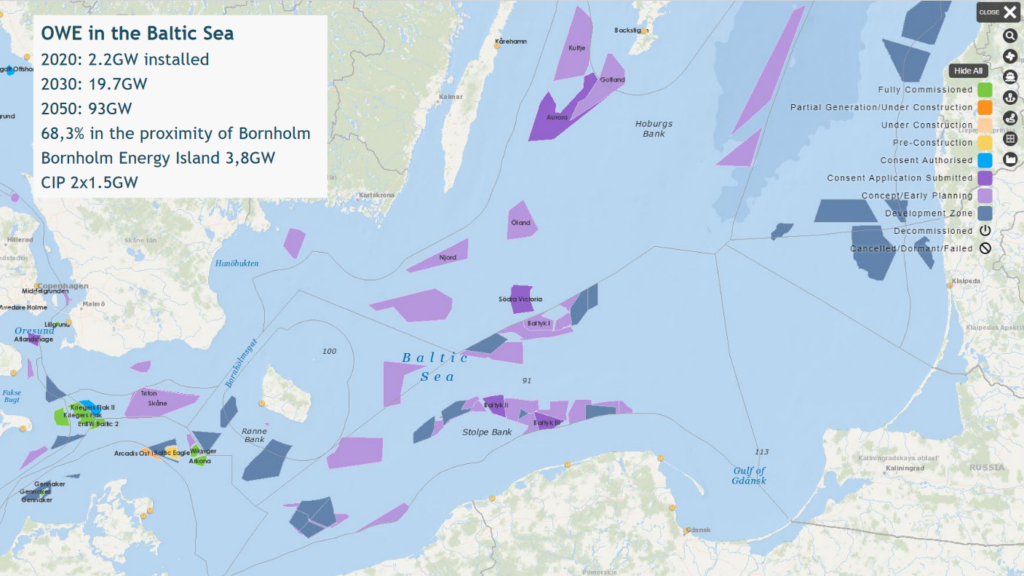

By 2030, the Baltic Sea areas south and east of the Danish Island of Bornholm will be home to up to 20 GW of offshore wind installations, a major increase from today’s 2 GW. One of these offshore wind parks is the Bornholm Energy Island, which is expected to produce 3.8 GW green electricity when operational. Of the 3.8 GWs, 800 MWs are considered “over-planting”, and this capacity will instead be targeted for a Power-to-X facility.

What will the “X” be used for? Today, 60,000-plus vessels pass Bornholm on their way to and from Baltic ports. By 2030, that number is expected to increase to 80,000. The production of shipping fuel from offshore wind energy off Bornholm Island therefore has a potential market right on its doorstep. And this is the whole rationale behind the Bornholm Bunkering Hub.

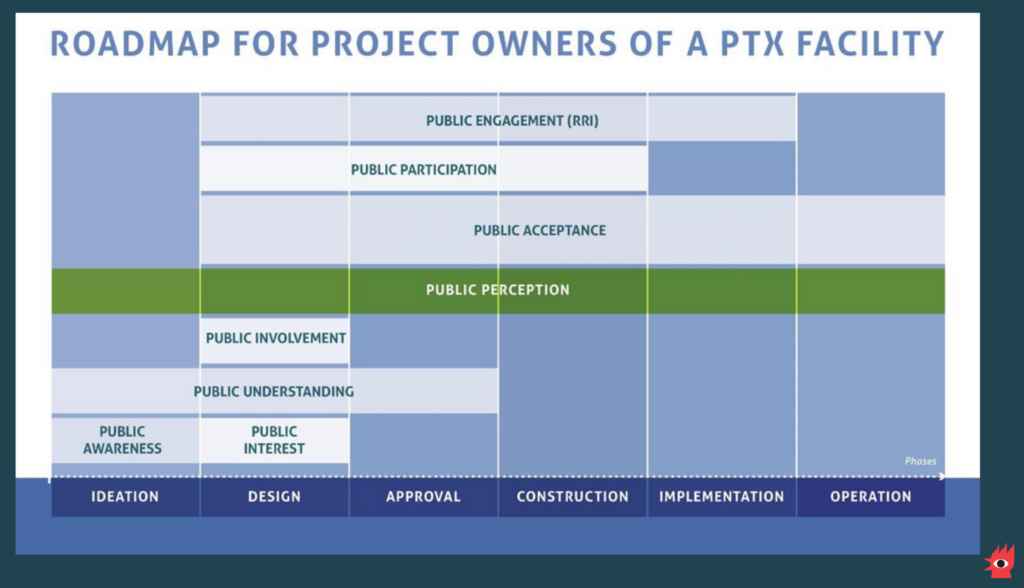

Maja Bendtsen, CBO Bulk at Port of Roenne, explained that the many feasibility studies currently ongoing are being done in broad industry partnerships, utilizing competencies across the value chain. The size and configuration of the Power-to-X facility, how it can be integrated with the local energy system, and where the plant and ammonia storage can be located, are all issues now being critically assessed. By doing “fast-simulations” of many different approaches, the various parties hope a plan forward will be finalized by 2025. One of the key enablers for the realization of the project are the locals, the people of Bornholm. Including them early via open and inclusive dialogue is a priority.

Deciding what is an acceptable risk

Jan Gramkov is a Risk & Safety Engineer at Rambøll, who are one of the partners for the Bornholm Bunkering Hub. Their approach to assessing the risk for ammonia bunkering in Bornholm is based on standard risk acceptance criteria & process safety management. In this analysis, the level of risk is assessed as a product of consequence and likelihood: eg. how likely is an uncontrolled release of ammonia and when released how severe is the consequence in a given situation. If the resultant risk is considered unacceptable, mitigation measures need to be employed. Simulations are used to indicate the consequence level and effectiveness of mitigation measures employed.

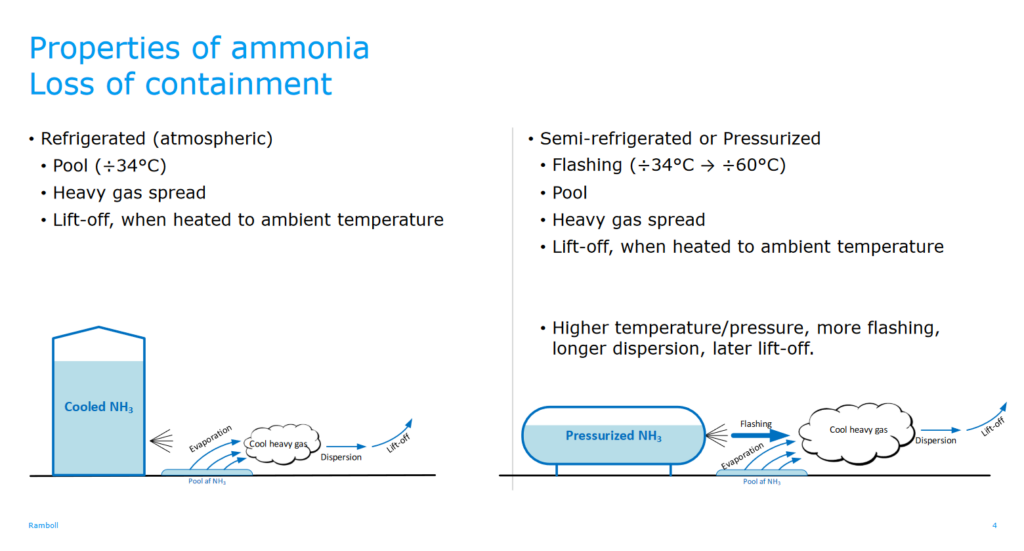

Jan continued, describing the differences between refrigerated, semi-refrigerated or pressurised ammonia storage, and how the amount of ammonia gas released at an accident are different for these options. There is a general conclusion: the higher the temperature and pressure, the higher risk profile if you have loss of containment. Storage tanks, tank overflow, tank inspection, loading and unloading, these are all parts of the process safety management design. At the end of the day, even for a brand-new process like ammonia bunkering, decisions will be based on the level of risk that will pass standard risk acceptance criteria.

Listen, communicate, and involve early

Nicklas Koch, Project Manager – Advanced Fire Engineering, Maritime and Energy, DBI, introduced the topic of safety perception. Quite apart from process safety management, this introduces a human element, and what people are prepared to do in emergencies.

Nicklas shared an example of EVs on a car carrier, where onboard staff had training in fire safety of electrical vehicles and were therefore confident to deliver the cargo safely to port. Without such training, their existing safety perception of EVs may have given them a different risk acceptance. This may result in people being unwilling to act in emergency situations. Nicklas explained that “people react differently depending on what source of information they have, especially with regards to the introduction of new technology”. This makes rigorous safety training for new processes like ammonia bunkering critical. It also familiarizes the frontline workers with the new processes and situations, making them less likely to be influenced by outside information.

The pressure cooker comparison

What does it mean, from a safety perspective, to have ammonia refrigerated, semi-refrigerated or pressurized? What happens if there is a tank rupture? Jan gave us the pressure cooker example: “If you cool ammonia down to boiling temp, the amount that comes out at rupture will be less forceful, like from your [tea] kettle. If you did the same in a pressure cooker – you [would] have much more coming out”. When asked if ammonia could potentially be flared, Jan replied, “This should be possible, but these solutions need to be developed. You can also flare it through a water basin. Like a scrubber.”

Collaboration and cross-sectoral knowledge transfer

Safety standards for ammonia port operations are urgently needed, but speed must not have priority over structure and alignment. “My fear for the introduction of new fuels, is that we have different standards, and [thus] the implementation will take longer than necessary, particularly with how you bunker a vessel. There is a need for safety measures, [but we] need to have the same across the industry, not every port having their own system”, Maja voiced.

For Jan, the development of ammonia safety standards can use valuable existing work, such as accidents assessments from the oil and gas industry, and standards from the ammonia fertiliser or ammonia cooling industry. “We combine existing knowledge and try to ensure compatibility in the different interfaces”, Jan continued. “There are lots of [bunkering] procedures in the IMO which we can (and should) ‘steal’”, he added.

Bringing in the human element

Dealing with humans – in any kind of technical operation, the introduction of new risk, is always difficult. Nicklas replied, “humans can also be a mitigation to the risk. It’s always important to consider a human’s role in a risk assessment in how bunkering operations are done”. Nicklas continued emphasising the importance of training. The better trained you are, the higher the security level, as is your awareness of how trained & capable you are. “Knowing why you do something is very important”, Nicklas argued. “If you understand your role, you will more likely be able to mitigate”.

Rounding up, the panelists gave their answers to a hypothetical: what main challenges have been overcome in 2030 to reach where we need to be on the maritime energy shift trajectory? They answered:

- (Nicklas) To reach public acceptance of safety levels, i.e., to manage to communicate safety levels to the public, and that they are understood.

- (Jan) To manage ship interface between ship and shore, so that you can bunker anything anywhere.

- (Maja) To manage to put all the right stakeholders together, so that we can accomplish what has taken us 80 years (for oil), in 8 years for ammonia.