Small-Scale Ammonia Synthesis Technology on Track for 2021

By Stephen H. Crolius on December 12, 2019

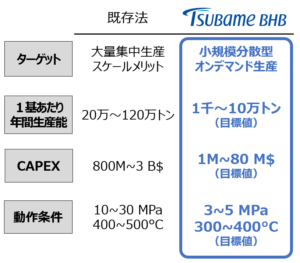

On October 6, 2019, the Nihon Keizai Shimbun published an article that confirmed a goal set at the 2017 launch of Japanese chemical technology developer Tsubame BHB. The goal is to have Tsubame’s ammonia synthesis technology ready for licensing in 2021. According to Tsubame’s English-language website, its technology “makes it possible to produce ammonia even at small-scale plants” – good news for ammonia energy project developers interested in distributed production concepts.

The central figure behind Tsubame’s technology is Institute Professor Emeritus Hideo Hosono of the Tokyo Institute of Technology (TIT). Hosono, who directs TIT’s Materials Research Center for Element Strategy, is noted for his accomplishments in a variety of material science fields, including semiconductors and superconductors. Among other awards and honors, he received the Japan Prize in 2016, and was elected as a Foreign Member to the United Kingdom’s Royal Society in 2017.

The Tsubame ammonia synthesis process is based on a novel catalyst developed by Hosono and his TIT colleagues. The catalyst includes the element ruthenium, which has long been investigated for its potential in ammonia synthesis processes. Hosono’s innovation was to “load … ruthenium nanoparticles” on a substrate composed of a novel compound his team had developed while engaged in superconductor research. This compound, whose base form is referred to as C12A7, consists of calcium and aluminum oxides that are transformed at the atomic level to produce an electride (a special category of ionic compound), that manifests a high degree of chemical stability. When ruthenium is combined with the electride C12A7:e, the resulting catalyst, according to a Tsubame Web page, makes “highly efficient ammonia synthesis … possible even under low-temperature, low-pressure conditions.”

The Web page goes on:

The Haber-Bosch process, which has been used up to now for the synthesis of ammonia, requires high-temperature, high-pressure reaction conditions, so concentrated, high-volume production must be undertaken at a single large-scale plant that consumes huge volumes of energy, and which entails substantial capital investments. The practical application of the ammonia synthesis technologies being targeted for R&D at [Tsubame co-founder Universal Materials Incubator] … is expected to form the foundation of a model for the world’s first on-site ammonia production, through which ammonia can be produced where it is needed, and in the volumes required.

“Pioneering on-site ammonia production: Collaboration with Ajinomoto and UMI,” Tokyo Tech News, April 25, 2017

Universal Materials Incubator is a Japanese investment firm that, per its website, was founded in 2015 to “strengthen Japan’s technological capabilities by fostering outstanding material and chemical companies, and cultivate an industry structure that can compete in the global arena.” It took a lead role in the founding of Tsubame in 2017 and holds a majority of the ownership shares. Also prominent in the founding group is Japanese food and biotechnology company Ajinomoto. Ajinomoto’s interest was not random. As related in a contemporaneous TIT press release, “Ajinomoto Co. produces various types of amino acids, including glutamic acid [including in the form of monosodium glutamate], and other fermentation materials, by using large volumes of ammonia as a raw material, so the company has long been captivated by the revolutionary fundamental technologies discovered and invented by Prof. Hosono and his group to achieve the low-cost, stable supply of ammonia.”

The press release says that Ajinomoto had already been “working toward achieving on-site ammonia production at its own plants” prior to Tsubame’s foundation. The schedule enunciated at the time of founding calls for implementation of “the world’s first on-site ammonia production by around 2021” in Ajinomoto’s fermentation plants. Ajinomoto’s goal is to “increase the cost competitiveness of its fermentation materials.” Thereafter, “Tsubame BHB will strive to expand applications in areas such as agricultural fertilizers, food products, pharmaceuticals, and chemical products.” The Nihon Keizai Shimbun article indicates that, two and a half years later, the timeline is still on track.

In the meantime, Hosono’s research continues apace. A robust rate of publication suggests that his team is hitting its stride in the field of electride-based catalysts. A paper that appeared in a recent edition of Chemical Science is indicative: “Acid-durable electride with layered ruthenium for ammonia synthesis: boosting the activity via selective etching.”