The Ammonia Transition: panel wrap-up from the Ammonia Energy Conference

By Julian Atchison on February 26, 2021

What key challenges lie ahead as ammonia producers embark on the transition to low and zero-carbon ammonia? What are the big producers already doing to smooth and later accelerate this transition? On November 19, 2020, the Ammonia Energy Association (AEA) hosted a panel discussion moderated by Steve Crolius from Carbon Neutral Consulting, as well as panel members Sammy van den Broeck from Yara, Ashraf Malik from CF Industries, and Trevor Williams from Nutrien as part of the recent Ammonia Energy Conference.

The transition ahead

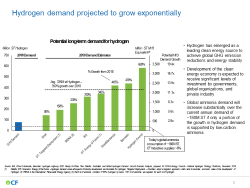

Panel moderator Steve Crolius was forthright in his assessment of the challenges ahead. The ammonia industry is going through one of the biggest transitions any industry has ever had to go through. The key elements of this transition include not only moving away from fossil fuel-based feedstocks, but also an expansion of the ammonia market to include energy customers and end-use applications. No one knows exactly how much increased global production is needed to accommodate these new demands, but an order of magnitude higher (10x current levels) is certainly not out of the question. That’s a giant leap from where we are currently, presenting a unique set of challenges and opportunities for global ammonia producers.

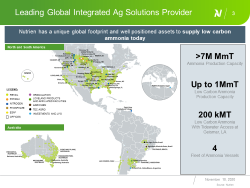

To find out how the industry is working through this transition, we were thrilled to have the three largest ammonia producers present in the same virtual room. CF Industries is the world’s largest ammonia producer (10Mt/year), closely followed by Yara (8Mt/year) and Nutrien (7Mt/year). Thus, more than 10% of annual global ammonia production capacity was represented in our conference panel to present insights. How will they meet emission reductions obligations, meet the huge increases in demand for a low and zero-carbon product, and what lessons have they learned so far in their decarbonisation efforts?

Yara

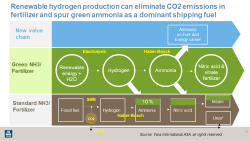

As already highlighted in our marine ammonia panel, Yara are focused on a whole value chain approach to decarbonisation. They also recognise that low and zero-carbon ammonia has benefits across all areas of business. Sammy van den Broeck is confident green ammonia is the zero-carbon fuel of choice for shipping, can help decarbonise global food chains, and will be a key part of the world’s future energy mix.

For Sammy, it’s key to match up the existing global network of production, transport and storage infrastructure with slowly rising demand in key geographies (namely Europe, Asia and North America). Harmonisation of current assets with future demand will smooth the transition and ensure green ammonia can be moved from countries where clean energy resources are high (eg. Australia) to countries where demand is high but production capabilities are low (eg. Japan). As far as marine fuel is concerned this may be very straightforward, as current bunker fuel hubs (Texas, Rotterdam, Hamburg, Singapore etc.) are located adjacent to regions with high green ammonia production potential. Yara are already demonstrating the variability of green ammonia production with a portfolio of tangible products: the full electrification of its Porsgrunn ammonia production plant in Norway (new partners and developments have been announced post-conference), green ammonia production at its Pilbara plant in Australia (again, new developments have since been announced), and ammonia from offshore wind in the Netherlands.

But although these demonstration projects are fully-funded, Sammy believes a premium on green ammonia will still be required to encourage production and purchasing. Yara also is working hard to develop green ammonia off-take amongst its existing customer base. The additional key challenge is technology costs: although current technologies have residual carbon emissions, their levelised cost of ammonia beats out future, green, emissions-free technologies handily. Support is needed to kick off the widespread utilisation of these future pathways. The high cost of electrolyser stacks isn’t the only issue: total costs for green ammonia projects are still well above 1000 €/kW.

Yara is ready to “jump off the cliff”, but Sammy finished by outlining the key challenges ahead:

- Need for early support mechanisms to encourage off-take and reduce technology costs

- Certification

- Scale and load factors (ideally we need to kick-off as large as possible)

- Market creation in agriculture and shipping for a truly green product

- The urea dilemma

CF Industries

Over the last twelve months, Ashraf Malik and CF Industries have been struck by the emergence of hydrogen as a leading source of clean energy and the sheer scale of the opportunity. Ammonia’s role as a hydrogen and energy carrier is almost assured, so how do current producers prepare for the increasing demand for green ammonia?

Ashraf sees high scalability potential across key ammonia infrastructure networks, including CF Industries’ North American assets. The company’s Donaldsonville production facilities are the starting point for its decarbonisation efforts, with an electrolyser to be installed that will be powered by renewable energy (purchased by a power off-take agreement, not generated onsite). Once the economic case stacks up, it will be easy to substitute green hydrogen into any one of the six ammonia plants at Donaldsonville and scale up production.

Although the current economics of green ammonia are challenging, the current economics for blue ammonia are not. Infrastructure for transporting processed CO2 around the Gulf Coast is well developed, so using waste CO2 in sequestration or combustion is a viable option for CF Industries, and does not affect their current product mix. This is part of the incremental approach Ashraf and the other panelists promote: achieve emission reductions now using best and lowest-cost technologies while the economics for green products improve.

Ashraf also sees a lot of signs that the early support to kick-start green ammonia production will be forthcoming. Government incentives for sequestration and renewable projects are well-established (which inspires confidence). Producers can and should have constructive, ongoing partnerships with technology providers who can do the development work behind the scenes to bring down the cost of future production technologies. And CF Industries isn’t sitting back and waiting for customers to change their habits: a “push and pull” approach to creating a market for premium green ammonia is their preferred method, where they work closely with their customers to accelerate the take up of low and zero-carbon ammonia.

(In a post-conference development, CF Industries has joined Hydrogen Forward: a body with the explicit purpose of lobbying the United States government to pursue a national hydrogen strategy).

Nutrien

Trevor Williams began by pointing out that Nutrien is in a unique position amongst the big producers, with roughly 1/7th of its global production already being blue ammonia. Though blue ammonia is not the long-term solution to decarbonising the industry, it’s currently cost-effective and fits into the notion of the incremental approach, which Trevor also calls “continuous improvement”. Though the analogy is crude, continuous improvement should see the industry moving steadily through the ammonia color spectrum from black, grey, dark blue, blue and turquoise to finally reach green, instead of making giant leap at some point in the next decade or so. Thankfully, it’s not just sustainability considerations driving this process anymore – the business case and the flow of capital is now starting to add up.

Nutrien has learned a number of key lessons in developing its low-carbon ammonia projects, which Trevor was keen to share with us:

Sustainability isn’t just about the environment. For Nutrien, it’s based on three pillars that all have to be maintained:

- Society (public desire for the project),

- Government (policy support for the project), and

- Industry (project viability).

And, this transition will be achieved via several key steps:

- Establishing a vision. The detail is not complete yet, but we can certainly see pathways from blue to green ammonia.

- Understand the problems. Which of the pillars need attention?

- Create the path. It’s not a flick of the switch, this will be gradual.

- And begin your journey! Sessions like these demonstrate this is already occurring at the big ammonia producers, giving Trevor confidence we’re moving in the right direction.

If you wish to view the archived video of the ammonia transition panel discussion, please register for the conference to access all session recordings. You can also browse and download all of the Ammonia Energy Conference 2020 presentations.