The Cost of CO2-free Ammonia

By Bunro Shiozawa on November 12, 2020

Editor’s note: Bunro Shiozawa is a Senior Associate at Sumitomo Chemical Company. He has played a unique role in building the case for ammonia as a hydrogen carrier, serving from 2014 to 2018 as Deputy Program Director of Japan’s SIP “Energy Carriers” initiative. Over the last year he published in the on-line journal of the International Environment and Economy Institute a ten-part series of articles that describe and reflect on the work done by him and his colleagues, and its impacts in Japan and beyond. The article that follows is Shiozawa’s English translation of his series’ part 6.

If ammonia is to be introduced into the energy system as a CO2-free fuel, its cost must be at least competitive with that of other CO2-free fuels such as CO2-free hydrogen. In the discussion below I consider the cost aspect of CO2-free ammonia.

To state my conclusion at the beginning, the cost of CO2-free ammonia can be less than 30 yen/Nm3-H2, which is the 2030 cost target for hydrogen energy set by the Japanese government in its Basic Hydrogen Strategy[1] for introducing hydrogen energy into Japan. Moreover, ammonia cost could even almost reach the level of 20 yen/Nm3-H2, which is the target for 2050. For ease of reference, the table below shows the cost per tonne of ammonia that corresponds with the government’s 2030 and 2050 hydrogen cost targets.

| Corresponding costs of calorific equivalent hydrogen and ammonia ($1=yen 110) | |

| Hydrogen Cost | Ammonia Cost |

| 20 yen/Nm3-H2 (~$2 per kg H2) (targeted cost of hydrogen for 2050 in the Basic Hydrogen Strategy) | $320 per tonne-NH3 |

| 30 yen/Nm3-H2 (~$3 per kg H2) (targeted cost of hydrogen for 2030 in the Basic Hydrogen Strategy) | $480 per tonne-NH3 |

Estimation of Production Cost of Ammonia

Production of ammonia was first commercialized by Haber and Bosch more than 100 years ago, and since then various improvements have been made to establish it as an industrial process. The energy efficiency of ammonia production using a natural gas feedstock in particular has almost reached the theoretical limit. A study by the International Fertilizer Industry Association in 2008 on energy efficiency of 93 ammonia plants in 33 countries[2] found that the top decile of energy efficient plants using natural gas as a feedstock achieves an efficiency of 32 GJ per tonne-NH3. The most modern plants come even closer to the theoretical limit with efficiencies of 28-29 GJ per tonne-NH3.

Under such circumstances, knowing the price of feedstock natural gas makes it possible to estimate the variable production cost of ammonia for each production plant. Specifically, the variable cost of ammonia ($ per tonne-NH3) can be approximated by simply multiplying the cost of natural gas ($ per MMBtu) by 30. If the cost of natural gas is $3.00 per MMBtu, for example, the variable production cost of ammonia from this feedstock would be about $90 per tonne-NH3. To estimate total production cost, the fixed cost of the plant (plant capital, labor, etc.), which varies with location and age of the plant’s facilities (and often other factors), must be added to the variable cost. A typical value for fixed cost would be $100-120 per tonne-NH3. Thus, the pre-shipment cost of ammonia produced in overseas regions where the cost of natural gas is around $3.00 per MMBtu can be estimated at around $200 per tonne-NH3.

The ammonia produced with this cost structure is of course the conventional variety, with the full greenhouse gas footprint that originates in the carbon embodied in the natural gas feedstock. To estimate the cost of carbon-free ammonia, the cost of removing CO2 by carbon capture and sequestration (CCS), with or without enhanced oil recovery (EOR), needs to be added. Such estimations have been made by independent public organizations, both domestic and foreign, as discussed below.

Estimation of the Production Cost of CO2-Free Ammonia

There are two ways to produce CO2-free ammonia: (a) ammonia produced using natural gas feedstock with the CO2 generated in the production process removed by CCS/EOR; and (b) ammonia produced from renewable hydrogen.

Since slightly more than 1.6 tons of CO2 is emitted per ton of ammonia production[3], the cost of producing CO2-free ammonia by production method (a) can be estimated by adding the cost of CO2 removal to the ammonia production cost.

The cost of producing CO2-free ammonia from renewable hydrogen is determined by the cost of the renewable hydrogen feedstock, which is largely dependent on the cost of the renewable electricity used to produce the renewable hydrogen through water electrolysis[4].

CO2-Free Ammonia Production Cost as Estimated by the IEA

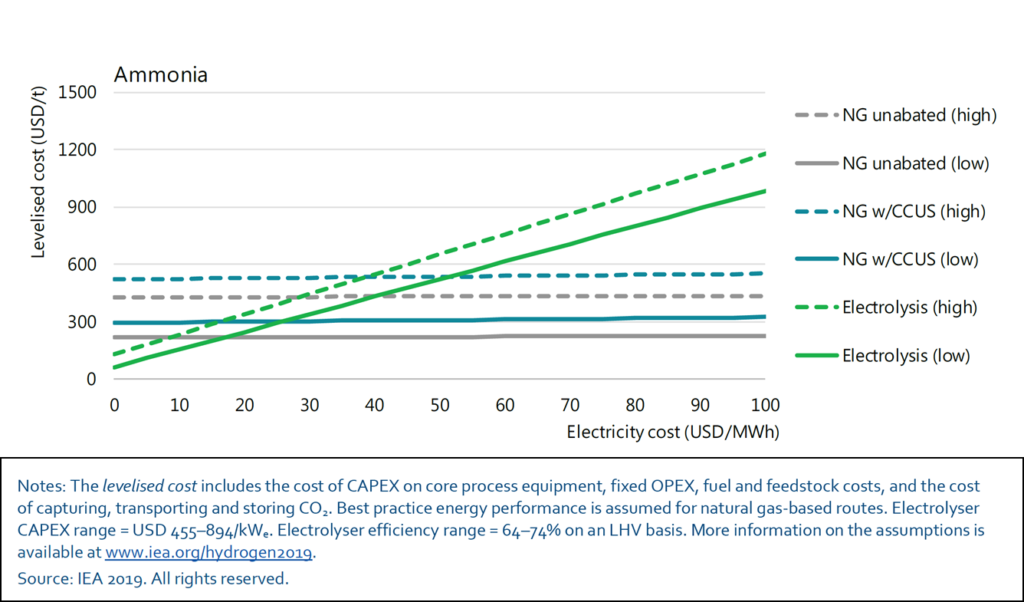

The International Energy Agency estimated production costs for CO2-free ammonia in its 2019 report The Future of Hydrogen, as shown in the figure below.

The analysis indicates the following:

(1) If natural gas is used as a feedstock and the CO2 emitted from the production process is removed by CCS, the production cost of CO2-free ammonia is about $300 per tonne-NH3 (assuming a natural gas price of $3.00 per MMBtu; this is the solid blue line in the graph.) At a raw natural gas price of $10.00 per MMBtu (blue dotted line), the cost of producing CO2-free ammonia is about $530 per tonne-NH3.

(2) If the cost of renewable electricity becomes cheaper than about $50 per MWh, the cost of producing CO2-free ammonia from renewable hydrogen may become lower than that from natural gas.

Note that the graph puts the cost of producing natural gas-based (non-CO2-free) ammonia at around $220 per tonne-NH3, at a natural gas price of $3.00 per MMBtu (solid gray line). This suggests that the IEA estimated the CCS cost of the CO2 emitted from ammonia production at about $50 per tonne-CO2, which increased the cost of ammonia by about $80 per tonne-NH3.

CO2-Free Ammonia Production Cost as Estimated by the IEEJ

A completely independent cost analysis for CO2-free ammonia was conducted under the auspices of the SIP “Energy Carriers” initiative by the Institute of Energy Economics, Japan (IEEJ). It was based on the following cases and assumptions:

- Construction of a new ammonia production plant with an annual capacity of 1.1 million tonnes in either Saudi Arabia, another Middle Eastern country, or North America;

- Natural gas feedstock priced at $3.00 per MMBtu;

- The CO2 generated in the production process removed by carbon capture at the production location;

- The resulting CO2-free ammonia delivered to Japan by ocean freight;

- Realization of a 10% equity internal rate of return (EIRR) as supplier profit[5].

The analysis shows that if CO2-free ammonia can be sold at prices between $276 per tonne-NH3 (for Saudi Arabia) or $300 per tonne-NH3 (for the other locations), the business will be profitable on the production side.

The EOR Effect

If an enhanced oil recovery field exists near the ammonia plant, the high concentration of CO2 emitted from the production process can be sold almost intact for EOR. In this case, the revenue from the process can be used to offset production cost. Since CO2 for EOR can be sold at about $20 per tonne-CO2, this would reduce the production cost of CO2-free ammonia by about $35 per tonne-NH3. The IEEJ analysis took this into account in its estimation of the cost of CO2-free ammonia produced in the US. This analysis makes clear that the availability of EOR can meaningfully influence the economics of CO2-free ammonia from natural gas.

Cost of CO2-Free Ammonia Arriving in Japan

The cost of transporting CO2-free ammonia to Japan and then to its point of use within the country needs to be added to the cost of production. This cost was estimated at $40-80 per tonne-NH3 by the IEEJ study. Logistics costs vary depending on the point of origin, the size of the ship, and the number of times the product is loaded and unloaded. For the Middle East to Japan, logistics costs are $40 per tonne-NH3; for North America to Japan, $80 per tonne-NH3. In both cases, very large gas carrier (VLGC) vessels are used with approximate capacity of 80,000 m3.

According to these analyses, the cheapest CO2-free ammonia would be the one produced in the Middle East. The cost of this CO2-free ammonia after logistics costs were taken into account was estimated by the IEEJ at $320 per tonne-NH3, or about $340 per tonne-NH3 according to the IEA’s estimated production cost of CO2-free NH3 including the cost of delivery to Japan as estimated by IEEJ.

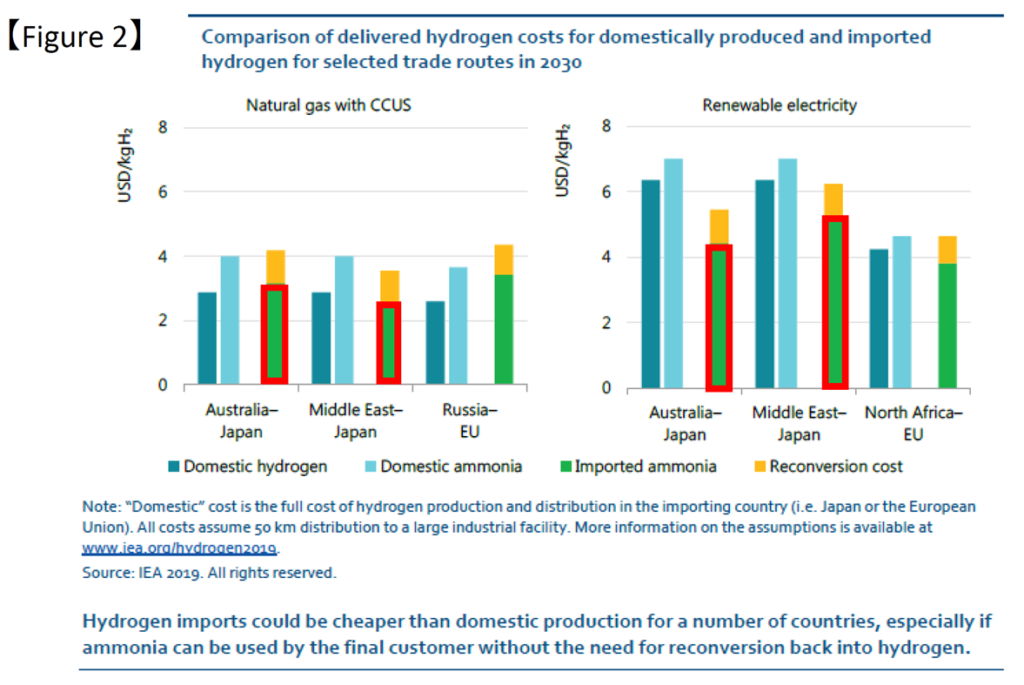

The validity of this cost estimate is supported by another IEA analysis. The figure below shows the IEA’s cost estimate for importing hydrogen energy in the form of CO2-free ammonia from Australia and the Middle East to Japan, and from Russia to the EU. (Here, the cost of CO2-free ammonia is indicated as the calorific-equivalent hydrogen cost ($ per kg-H2)). The value of the red-framed bars in the left-hand panel, which correspond to the cost of CO2-free ammonia from the Middle East to Japan, is almost in line with the results estimated by the IEEJ above. More specifically, in the left-hand panel, the cost of importing ammonia from the Middle East to Japan in the form of CO2-free ammonia, produced from natural gas with subsequent CCS, is estimated at about $2.30 per kg-H2 (about $360 per tonne-NH3). This cost includes 50 km of inland transportation cost in Japan. (Note that we are discussing the cost of CO2-free ammonia before it is reconverted to hydrogen because CO2-free ammonia can be used as a fuel as it is, without reconversion to hydrogen).

Two conclusions can be derived from these analyses. First, the estimates suggest that the cost of CO2-free ammonia arriving in Japan is likely to be around $350 per tonne-NH3. Since the actual price of CO2-free ammonia available to Japanese users will be determined by negotiations between buyers and sellers, there is little point in discussing the individual cost estimates in more detail. What is important is to assess the social implementation potential of CO2-free ammonia from this cost level of roughly $350 per tonne-NH3 derived from these analyses. This cost level corresponds to about 22 yen per Nm3-H2, as can be seen from the table at the beginning of the article, which almost meets the 2050 cost target for hydrogen set by the “Basic Hydrogen Strategy.”

Second, until around the year 2030, the cost of CO2-free ammonia from a combination of natural gas and CCS will be considerably cheaper than that of renewable hydrogen. This is shown in the figure immediately above, where the estimated cost of CO2-free ammonia produced from renewable hydrogen in Australia and exported to Japan is estimated to be about $4.40 per kg-H2 (equivalent to about $700 per tonne-NH3, just about double the cost of CO2-free ammonia produced with CCS). After 2030, however, the IEA expects that the cost of producing ammonia from renewable hydrogen will eventually fall to less than half its 2030 level[6], as the cost of renewable electricity decreases further and related technologies advance.

References

[1] Decided by Relevant Ministers Council on Renewable Energies and Hydrogen Energy of the Japanese government in December 2017.

[2] Energy Efficiency and CO2 Emissions in Ammonia Production 2008-09 Summary Report, International Fertilizer Industry Association, September 2009.

[3] IEA, The Future of Hydrogen, June 2019

[4] The ammonia production cost of this method can be estimated by the chemical reaction formula of ammonia synthesis (1/2N2 + 3/2H2 → NH3) and energy efficiency of hydrogen production by electrolysis.

[5] “A Feasibility Study on the Supply Chain of CO2-Free Ammonia with CCS and EOR,” IEEJ, February 2019

[6] Figure 22, IEA, The Future of Hydrogen, June 2019