Thorium-powered ammonia production in Indonesia

By Kevin Rouwenhorst on October 19, 2023

In our September episode of Ammonia Project Features, Mulyono (Pupuk Kaltim) and Thomas Jam Pedersen (Copenhagen Atomics) discussed nuclear-powered ammonia production in Indonesia, including a new project being developed by the two organisations in Bontang, East Borneo. The recording is available on the AEA’s Vimeo channel, and you can download the speaker presentations.

Pupuk Kaltim: southeast Asia’s biggest fertilizer company

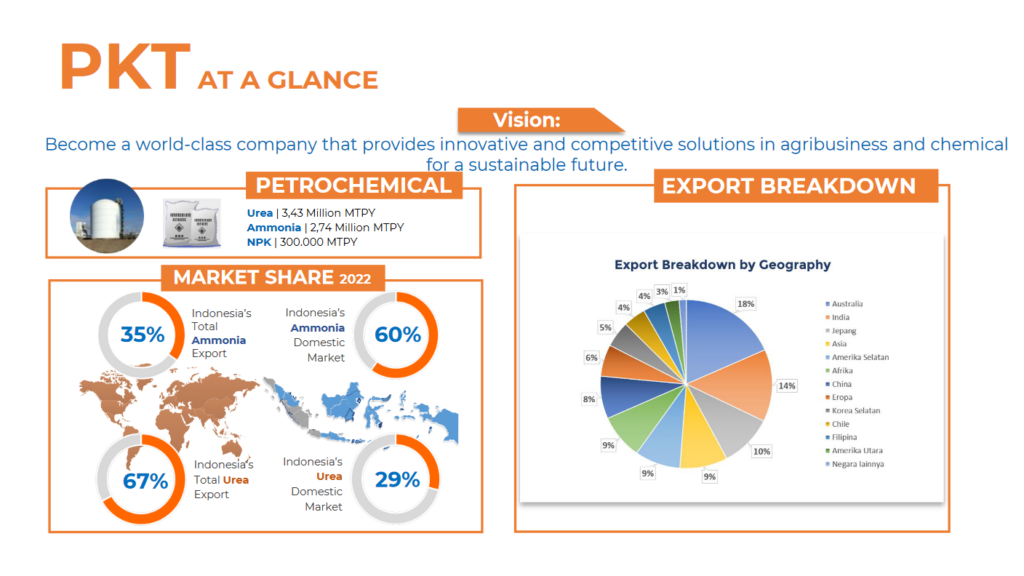

Pupuk Kaltim is an Indonesian state-owned fertilizer production company located in Bontang, East Borneo. Pupuk Kaltim produces a total of 2.74 million tonnes of ammonia annually from five ammonia plants licensed by KBR and Topsoe. This makes Pupuk Kaltim the largest fertilizer company in southeast Asia. The produced ammonia is mostly converted immediately to urea and ammonium nitrate fertilizers.

In 2021, Indonesia exported about 0.90 million tonnes of ammonia according to the World Bank. Pupuk Kaltim contributes about one third of ammonia exports from Indonesia, which is mainly shipped to other Asian countries and Australia. Pupuk Kaltim has significant ammonia storage infrastructure to facilitate these exports, with 100,000 tonnes storage capacity spread over 3 tanks and 6 jetties able to accommodate ships up to 55,000 deadweight tonnage (DWT).

Copenhagen Atomics: commercializing Thorium-fed reactors

Copenhagen Atomics is a Danish start-up aiming to commercialize modular thorium-fed reactors (40 MW-sized) for nuclear heat and power generation. It aims to mass manufacture these modular thorium-fed molten salt nuclear reactors, which have been developed over the past 9 years. Thorium is more naturally abundant than uranium as a nuclear fuel. Furthermore, storage of nuclear waste is reduced from about 100,000 year storage down to 300 years upon transitioning from uranium to thorium.

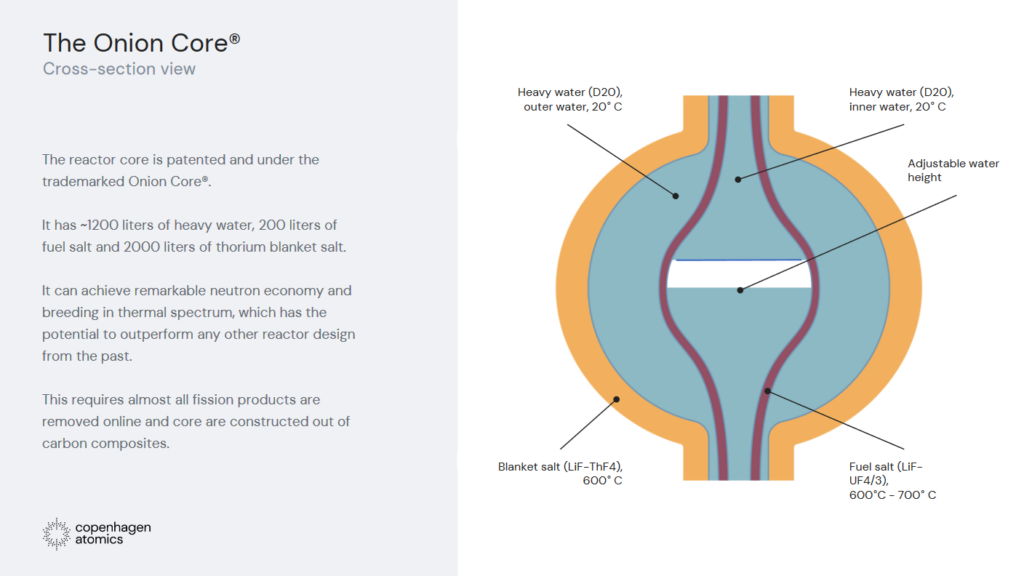

Currently, Copenhagen is building its first prototype reactor. At the heart of the nuclear reactor is the “Onion Core®” design, which has 1200 liters of heavy water (deuterium oxide), 200 liters of fuel salt, and 2000 liters of thorium blanket salt to run the nuclear reaction. The heat from the reaction is transferred to the molten salt at about 600°C. Then, the molten salt is cooled down with water that is evaporated to steam. The steam is then used in a turbine to generate electricity.

The Onion Core® reactors need about 100 times less fuel compared to conventional nuclear reactor configurations, reducing the requirement of nuclear fuel mining substantially, while also reducing fuel costs.

Corrosion due to operation with aggressive materials at elevated temperatures is generally perceived as a limitation for the development of thorium-fed molten salt nuclear reactors. However, Copenhagen Atomics has tackled this issue for the molten salt reactor operating at 600°C, as demonstrated with purified FLiNaK salt with over 2000 h operation. It is estimated that the reactor modules need to be replaced after 5 years. These modules can easily be swapped by heavy road transport, as the reactors are housed in 40 ft shipping containers.

Combining for nuclear-powered ammonia production

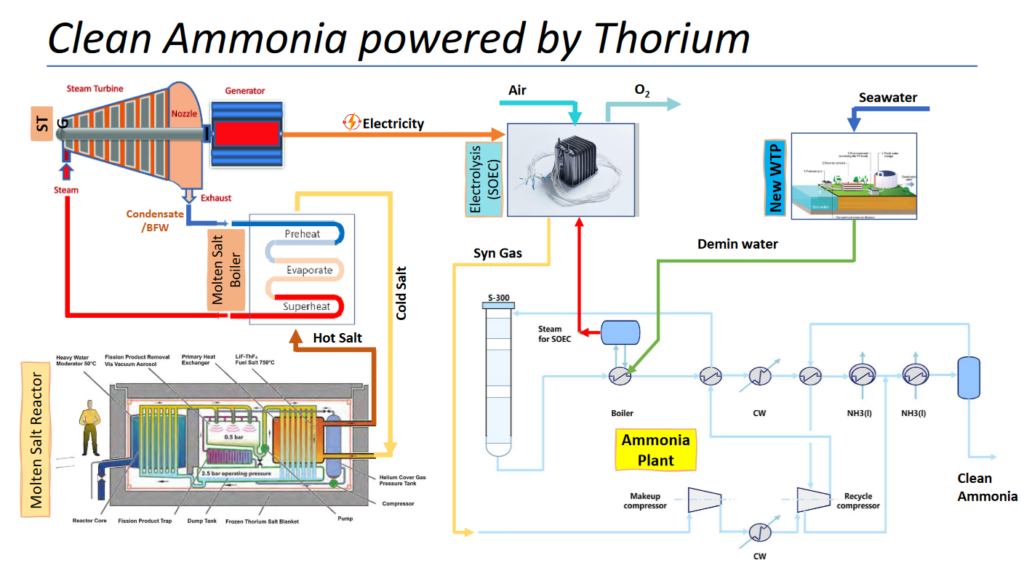

Recently, Pupuk Kaltim signed a MoU for the development of a nuclear-powered, 1 million tonnes per annum ammonia plant with Indonesian company Pertamina New & Renewable Energy and four Danish companies (Aalborg CSP, Alfa Laval, Copenhagen Atomics, and Topsoe). The project is located at Pupuk’s existing complex Bontang, Indonesia, and is based on an existing Topsoe ammonia synthesis loop. Hydrogen feedstock production via steam methane reforming will be replaced by solid oxide electrolyzers.

The project will use nuclear power and heat integrated with solid oxide electrolysis, such that the overall energy input of the ammonia plant is minimized. The 1 GW electrolysis capacity for the project will be powered by 25 modular thorium molten salt reactors developed and serviced by Copenhagen Atomics. Topsoe will provide and service the solid oxide electrolyzers, while Alfa Laval and Aalborg CSP are involved in the heat integration of the nuclear reactors and ammonia synthesis loop with the solid oxide electrolyzers.

The ammonia will be used for fertilizer production, with Pupuk also considering production of ammonium chloride and similar compounds. The project is estimated to produce sufficient fertilizer to cover food supplies for 45 million Indonesians, or about one-sixth of the country’s population.

Pupuk and Pertamina are also investigating other alternatives for next phases of decarbonization, including carbon capture and storage from fossil ammonia plants. Furthermore, geothermal power may be coupled with electrolysis on some Indonesian islands with volcanic activity.

Regulatory aspects

An important aspect of this project is compliance with codes and standards. Currently, Indonesia does not have nuclear power generation. Therefore, the project partners are in close discussion with local authorities to approve the design principles & ensure compliance. Generally, nuclear power plants are built for grid electricity generation, making this a pioneering (but challenging) project to develop.

Copenhagen Atomics’ modular nuclear reactors can be located anywhere in the world, especially in locations with limited solar and wind potential (like Indonesia). This potentially allows for ammonia production close to ports such as Singapore and Rotterdam, where ammonia can be immediately used as a fuel.