Tsubame BHB Launches Joint Evaluation with Mitsubishi Chemical

By Stephen H. Crolius on December 17, 2020

Last month Tsubame BHB, a Japanese developer of ammonia synthesis technology, announced the signing of a “joint evaluation contract” with Mitsubishi Chemical Corporation (MCC) that will focus on a novel ammonia separation membrane. The company, which started operation in 2017, is working on a method of ammonia synthesis that could allow economic production at scales 1-2 orders of magnitude below today’s plants.

A November 17 Tsubame press release identifies “zeolite membrane technology for selectively separating ammonia” as the subject of the cooperation with MCC. The term “zeolite” refers to a crystalized, microporous aluminosilicate material. Hundreds of zeolite varieties have been identified in nature or developed technologically. The MCC development effort resulted in a zeolite that can take the form of a rigid membrane that allows ammonia molecules to pass through but not hydrogen or nitrogen molecules.

The press release mentions the relatively small yields of ammonia that result from each pass of a hydrogen-nitrogen reaction mixture through a conventional Haber Bosch processing loop.

Therefore, the existing Haber-Bosch method … requires large-scale processes and expensive equipment. Therefore, if a reaction-separation type process can be developed where the produced ammonia is separated using a membrane, the conversion of raw materials in the reactor may significantly increase, which would reduce the recycling process and, in turn, reduce the size and cost of the plant.

Tsubame BHB, Realizing an Ammonia Production Process Using a Separation Membrane Conclusion of a Joint Evaluation Contract with the Mitsubishi Chemical Corporation—Collaboration for Achieving Ultra-Small Ammonia Production Technology Begins, November 17, 2020

While the MCC membrane exhibits the essential molecular selectivity, the partners are now investigating parameters such as long-term durability that will determine its fitness for industrial applications, and specifically “for the realization of an ultra-small on-site ammonia production process.”

The MCC membrane complements the ruthenium-based catalyst system developed by the Hosono Laboratory at the Tokyo Institute of Technology (TIT). The head of the laboratory, Hideo Hosono, is a Professor Emeritus at TIT. The catalyst system supports “high-efficiency ammonia synthesis under low temperature and low pressure conditions.” These “reaction conditions enable production in small-scale plants with annual output of several tens of thousands of tons or less.”

In October 2019 Tsubame commissioned a pilot plant with a nominal capacity of 55 kg per day (20 tonnes per year) at food producer Ajinomoto’s factory in the city of Kawasaki. According to an October 5, 2020 Tsubame press release, the fact that the plant has been able to “achieve continuous operation” represents “a major step toward commercialization.”

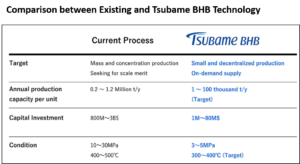

A company webpage sets the targeted range of plant capacities at 1 to 100,000 tonnes per year, with associated capital investments between $1 million and $80 million. Such small-scale ammonia production, in the company’s view, will allow the siting of plants at or near sites of ammonia consumption. The company projects that the resulting logistics economies will allow its plants to compete with ammonia producers whose distant manufacturing sites have lower production costs.

One target market will be fertilizers: “120 countries and regions did not produce ammonia in 2015. Therefore, these countries are unable to install large and expensive current ammonia plants and are purchasing expensive ammonia and nitrogen-based fertilizers from abroad.” An October 22, 2020 company press release describes an initial exploration of Laos as a potential host country for a plant based on Tsubame technology.

Green ammonia will be another target market: “There is much energy that cannot be fully utilized due to the lack of power lines, and we can propose a local production model for local consumption, which produces ammonia from water and air on the spot and uses it for various purposes such as chemicals and fertilizers,” or indeed as a “hydrogen carrier.”

An Ammonia Energy article from December 2019 described Tsubame’s intention to have its ammonia synthesis technology ready for licensing in 2021. The October 5, 2020 press release now frames the company’s goal as “achieving practical use next year.”

Note: This article was updated on December 18, 2020 to correct a factual inaccuracy.