Ammonia Energy Conference 2022

November 15, 2022 November 17, 2022 Phoenix Convention Center Phoenix USA

Schedule

Emerging Giants: decarbonizing ammonia in China, India, and the United States

Tuesday, November 15, 2022 8:30 am 10:30 am

Presentation

Envision Energy - green hydrogen and green ammonia business

Envision Group is a world leading net-zero tech supplier that aspires to solve the challenges for a sustainable future, with the integrated full value chain of the green new industry from upstream wind power supply to downstream industrial gases. Envision targets decarbonization at scale and offers a variety of solution such as sales of equipment & system, turn-key project handover, operation & maintainance and chemical process design solution. With a firm start in Chifeng city & Jinzhou port, Envision is right now constructing large scale green hydrogen & ammonia projects in mainland China, which will be on-stream by the end…

Enabling Net-Zero Energy

Tuesday, November 15, 2022 11:00 am 12:30 pm

Presentation

Program on combustion of ammonia and ammonia-hydrogen mixtures for power generation

GTI Energy and the Electric Power Research Institute (EPRI) have embarked on fundamental and applied investigations of ammonia as an alternative energy carrier under a joint program known as Low-Carbon Resources Initiative (LCRI). Focus is on applications under turbine operating conditions for both ammonia and ammonia-hydrogen mixtures. Participating teams members include the University of Central Florida (UCF), Georgia Institute of Technology and CRAFT Tech. Experimental, conceptual designs of combustors and computational efforts are underway since late 2021 and results to-date will be presented. The presentation will also include expanded tasks related to in-depth pursuit of the topic made possible through…

Presentation

Economic analysis for hydrogen - ammonia decarbonization of a natural gas plant - a phased approach

This paper summarizes a comprehensive technical and economic analysis of a hydrogen-ammonia upgrade to an existing 42 MW natural gas plant. A phased approach is carefully chosen which deploys low-carbon technology in modules which are palatable by large-scale utility customers. The objective is to minimize capital costs of the conversion while maximizing decarbonization as each phase is deployed. A phased approach delivers optionality to utilities which are often locked into carbon-emitting technologies by protracted investment durations. Phase one details implementation of an on-site thermal pyrolysis system. Existing natural gas infrastructure and plant waste heat are used to provide clean hydrogen.…

Presentation

Ammonia for power generation: a new, efficient, low-emissions generator made possible with software enabled technology and precise flameless reaction control

Customers who have historically wanted to use ammonia for power generation have been limited to co-firing with coal or diesel in order to overcome ammonia’s high ignition temperature and slow chemical kinetics. This process comes at a price; carbon emissions, added costs for blending, and significant drops in power output. Fortunately there is a new and cost effective alternative for ammonia-based power generation, one that’s uniquely positioned to run off of 100% ammonia without any reductions in power or efficiency. Precise reaction control, thanks to software-enabled technology, permits the Mainspring Linear Generator to manage fuel compression ratios and utilize a…

Presentation

Sunborne Systems: bringing keystone technologies to market for the global zero-carbon energy infrastructure

At Sunborne Systems, we are developing zero-carbon ammonia-based solutions for heavy transport and high-energy industrial applications. Our keystone technologies are initially focussed on early opportunities in the maritime industry and have high disruption potential across multiple other hard-to-abate sectors. Sunborne Systems was announced a year ago at COP26 in Glasgow and is a joint venture technology company formed by STFC, Reaction Engines and IP Group building upon the technical strengths of Reaction Engines and STFC in thermal management and catalyst chemistry and their in-common expertise in system design and optimisation.

Advancing Maritime Ammonia

Tuesday, November 15, 2022 11:00 am 12:30 pm

Presentation

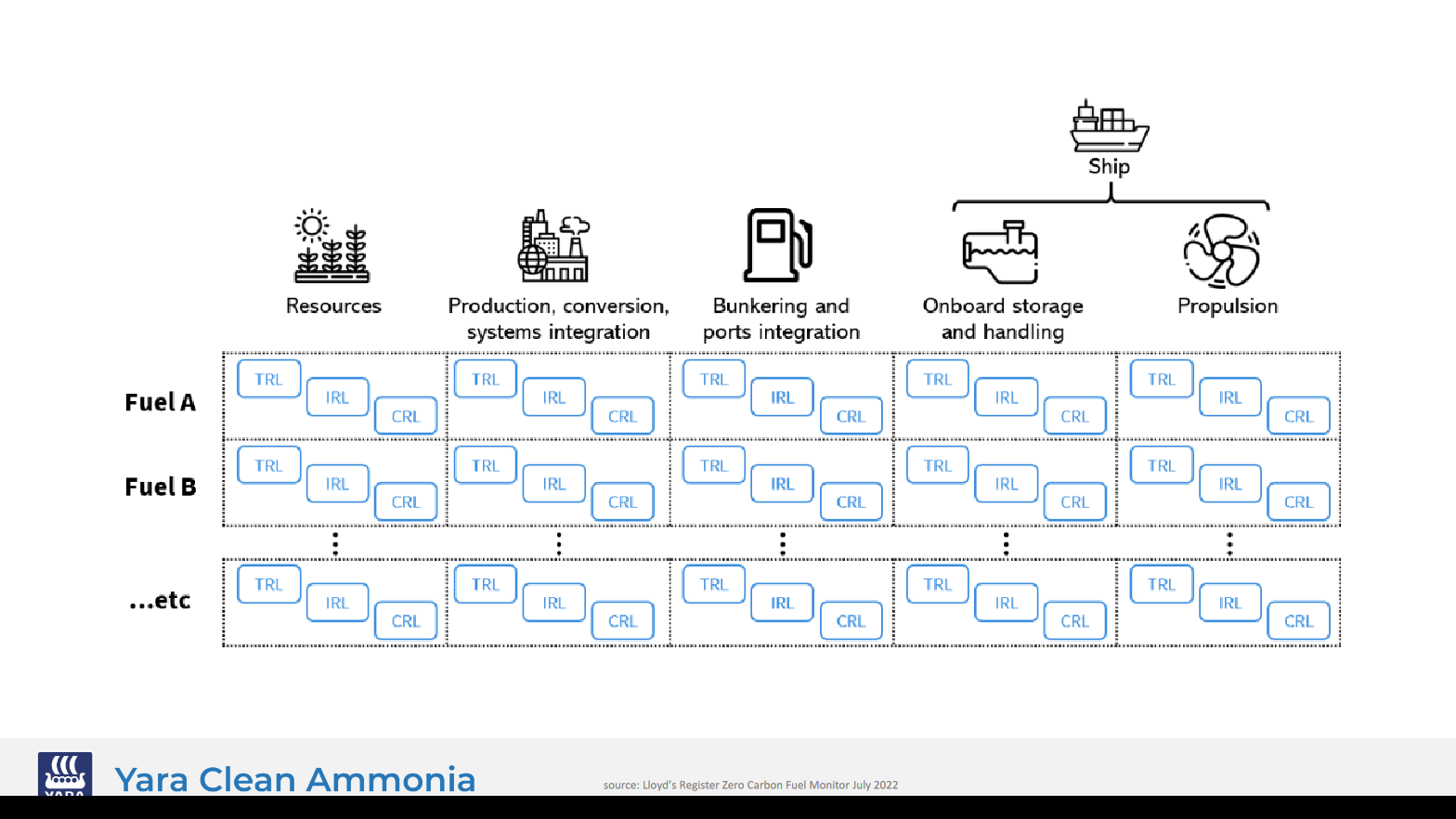

Trends, priorities and examples for increasing ammonia shipping fuel readiness levels across the value chain

The presentation will review the readiness levels of the different steps of the ammonia shipping fuel value chain from various perspectives, based on the recent Zero Carbon Fuel Monitor from Lloyd’s Register. Examples of concrete projects that Yara is working on to advance the readiness levels will also be shared.

Presentation

Ammonia as a marine fuel – bunkering operation and dispersion simulations

Global warming is linked strongly to increased greenhouse gas (GHG) concentration in the earth’s atmosphere. The maritime cluster plays a critical role in reducing GHG emissions by replacing fuels of fossil origin with low-carbon or carbon-free alternatives. As a carbon-free fuel, anhydrous ammonia has received much attention recently due to its established production technology, distribution infrastructure, and satisfactory energy density as a marine fuel. Unlike normal ambient liquid fuels, ammonia relies on refrigeration or pressurization to maintain the liquid phase. Boil-off gas (BOG) can be generated at constant pressure by the addition of heat to saturated liquid and involves significant…

Presentation

Ammonia terminal in port areas: safety and image issues in storage, throughput and transport

Ammonia is an important carrier of hydrogen which is very interesting considering the search for alternative energy sources. The world is looking for ways to reduce our global carbon footprint, and this will give opportunities for ammonia. Preferred location for terminals are port areas, especially in situations where energy is obtained by solar energy and where ammonia is used as a way to transport this energy to less sunny parts where energy is needed. But how about the risks of storage, handling and transportation of ammonia? And what is the public image on the risks of ammonia, and how to…

Presentation

Accelerating maritime decarbonization via multi-sectoral integration

In addition to its role as a low-carbon maritime fuel, seaborne trade of ammonia will play a key role in global, economy-wide decarbonization. Therefore, marine ports are emerging as likely future hubs for low-carbon ammonia, both as cargo and as a fuel. In many ports, adjacent industries such as refining, chemicals, and land-based freight transport offer additional offtake opportunities for both low-carbon hydrogen and ammonia, and hydrogen offers solutions for decarbonization of port operations. As multi-modal, global-scale trade and demand centers, marine ports have the potential to serve as epicenters and integrators for low-carbon ammonia and hydrogen industrial clusters.

Workshop: Maritime Green Corridors – The Case For Ammonia

Tuesday, November 15, 2022 2:00 pm 3:30 pm

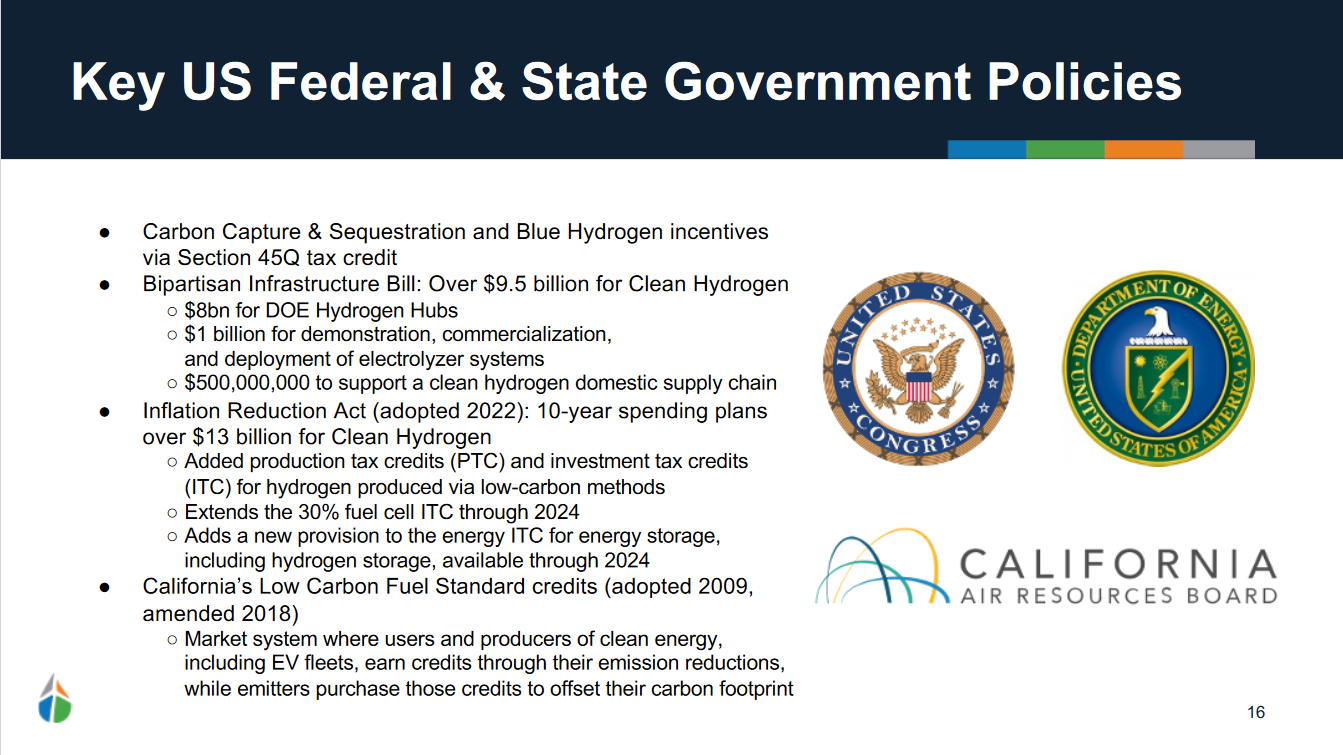

The Policy Landscape in the United States

Tuesday, November 15, 2022 4:00 pm 5:30 pm

Ammonia Sector Transition Strategy

Wednesday, November 16, 2022 8:30 am 10:30 am

New Ammonia Production Processes

Wednesday, November 16, 2022 11:00 am 12:30 pm

Presentation

NH3 & Energy Transition: a challenge meeting reality

Proton Ventures is an engineering firm focusing on ammonia solutions ranging from feasibility studies to EPC projects. Examples of previous realized ammonia solutions include large-scale, refrigerated ammonia storage terminals, including railcar loading/unloading facilities. Furthermore, a deNOx facility was installed in Kavala (Greece) for greenhouse gas emission reduction from a nitrate fertilizer facility. Proton Ventures has also been selected as EPC contractor for the Green Ammonia Pilot Plant (GAPP) project in Morocco, which will demonstrate 4 MTPD green ammonia production from simulated renewable energy patterns. The project includes alkaline electrolysis, PEM electrolysis, hydrogen storage, nitrogen purification, and an ammonia synthesis loop.…

Presentation

Demonstration project for a green chemical plant using large-scale alkaline water electrolysis

To achieve the carbon neutrality target set to be accomplished by 2050, hydrogen will play an important role in many sectors such as power, transportation, and industrial applications. Especially in the chemicals and fertilizers sectors, green ammonia, made by utilizing renewable energy as a feed stock, is expected to be materialized, and is also being considered as a hydrogen carrier with the advantage of easier transportation and handling than the hydrogen itself. Hence, in the near future, green chemical production facilities which are fed with hydrogen produced through the use of renewable energy will be installed instead of the conventional…

Presentation

Advanced technologies powering green ammonia R&D

Fujitsu has been working to find innovative solutions within the energy transition that would benefit from the company’s extensive experience in high performance computing (HPC), AI, quantum computation, materials science, molecular dynamics, and nanoscale materials development. Fujitsu has identified green ammonia as a field with technical challenges that could be addressed by the company’s unique capabilities and has partnered with an Icelandic start-up, Atmonia, to leverage HPC and AI technology in advancing electrochemical ammonia synthesis technology. This talk will provide an overview of the role of advanced technologies to speed up green ammonia R&D.

Presentation

Electrifying ammonia production using four metric tons per day (4 MTPD) Independent Ammonia Making Machine (IAMM™) units

Anhydrous ammonia price reached a historical high up to $1,700/short ton NH3 in mid-2022. In the meantime, Europe has shut down ammonia production at a capacity of over 3 million tonnes per year due to limited supply and the high cost of natural gas. AmmPower pioneers the development of the Independent Ammonia Making Machine (IAMM™) units, which allow decentralized production of green ammonia at a capacity of 4 MTPD using renewable electricity. The compact and modular IAMM™ units have multiple configurations, including electrolyzer and ammonia storage options. AmmPower delivers IAMM™ units at a low lump sum cost and a short…

Enabling Clean Ammonia

Wednesday, November 16, 2022 11:00 am 12:30 pm

Presentation

Low-carbon ammonia at LSB Industries

LSB Industries is the fifth largest ammonia producer in the US and operates three manufacturing facilities in Oklahoma, Arkansas, and Alabama. This year, the company announced its sustainability priorities and two major projects designed to reduce the carbon intensity of its ammonia production. The projects will reduce the companies carbon footprint by over 25% and consist of the construction of a carbon capture and sequestration facility to permanently sequester 450k metric tons of CO2 annually and the retrofitting of an ammonia plant to handle clean hydrogen from eletrolysis which will turn ~15% of the plant production into zero-carbon ammonia. Details…

Presentation

Making ammonia blue - the easy way

Production of low-carbon “blue” ammonia requires the addition of a carbon capture & storage (CCS) solution to the ammonia value chain. With the prevalence of geologic storage immediately below many US ammonia production facilities, onsite co-location of CCS facilities provides a number of attractive benefits to producers looking to make their ammonia low-carbon. Onsite CCS is a proven, ready-to-execute solution (the only two existing CCS projects in the U.S. today are co-located with emitting facilities) that delivers a lower cost, lower complexity decarbonization pathway for ammonia production, while simultaneously capturing the benefits of “outsourcing” CO2 disposal.

Presentation

Natural gas based, ultra-low carbon ammonia without fluegas scrubbing

Reducing the carbon footprint of ammonia is urgent more than ever, and requires new technology innovations to achieve this goal, while keeping these plants competitive and viable. In this session, we will review latest proposed technologies from thyssenkrupp Uhde to achieve ultra-low carbon emissions by implementing a new process flowsheet that replaces the common primary reforming approach and eliminates the need of a fluegas scrubbing system. We will also review the advantages of the new proposed technologies in terms of capex and management of risk associated with new technology implementation.

Workshop: Ammonia Sector Transition Strategy

Wednesday, November 16, 2022 2:00 pm 3:30 pm

Clean Energy from Ammonia

Wednesday, November 16, 2022 4:00 pm 5:30 pm

Presentation

Exhaust gas treatment catalysts for ammonia-fueled engines

Ammonia is expected to be a promising zero-emission fuel because it does not emit CO2 during combustion. However, the exhaust gas from the actual ammonia-fueled engines contains unburned ammonia, nitrogen oxides (NOx), and nitrous oxide (N2O), and there is a need to develop technologies to remove these harmful substances. Unburned ammonia can be removed by a catalytic combustion method using a conventional oxidation catalyst, but NOx and N2O are simultaneously generated as byproducts. Therefore, Nikki-Universal has developed a new catalyst that can remove ammonia at high efficiency while reducing the generation of NOx and N2O. We have also developed a…

Presentation

Ammonia cracker: design and safety considerations

Ammonia cracking is an endothermic reaction with characteristics similar to those of steam methane reforming. As a result, large scale ammonia crackers are likely to more than a passing similarity to the steam-methane reformers which are currently used to convert natural gas to hydrogen. When transferring technology from one industry to another the challenge is to distinguish between know-how which benefits the new application, and which should therefore be applied; and know-how which is detrimental to the new application and therefore needs to be either unlearnt or relearnt. The presentation will cover the choices facing the designer of a large-scale…

Presentation

Ammonia as a liquid for the future of aviation

Zero-emission aviation initiatives have mainly focused on using hydrogen or drop-in biofuels and sustainable aviation fuels (SAF) to replace fossil-based jet fuels to achieve near-term reductions in carbon emissions with minimal impacts on the global aircraft fleet and supporting infrastructure. Despite significant advances in the production of such fuels, scaling up manufacturing capability to be cost-competitive remains a challenge. This paper discusses ammonia as a carrier of green hydrogen for aviation, with near-zero emission. Ammonia is proposed as both a carrier of hydrogen as fuel and to provide cooling for compressor intercooling and cooled cooling air for core efficiency improvement,…

Clean Ammonia from Electricity

Wednesday, November 16, 2022 4:00 pm 5:30 pm

Presentation

Improving the competitiveness of Power-to-X projects in Chile

Ammonia synthesis represents the second largest hydrogen-consuming industry worldwide. In 2020, 33 million tonnes of ammonia were produced which accounted for 45% of the global hydrogen demand. The ammonia production industry annually generates nearly 0.5 Gigatonnes of CO2-equivalent which accounts for 1% of global greenhouse gas emissions. Zero greenhouse gas emmision targets and recent disruptions of the fossil fuel supply chains have made ammonia produced from renewable energy more attractive. The expectations for green ammonia demand were changed by the energy supply challenges being faced in Europe; the new demand expectations will have to be supported with developments on new…

Presentation

Large-scale, innovative alkaline water electrolysis

Industrial Hydrogen is used for many processes such as fertilizer production. However, 95% of the hydrogen used for these processes comes from fossil fuels. Globally, the ammonia industry emits ~400million tonnes CO2, which is ~2% of the total carbon emission. Next Hydrogen solutions from green energy can dramatically lower your carbon footprint, enhance reliability of supply and be justified on an economic basis. Founded in 2007 and based in Toronto, Next Hydrogen is a designer and manufacturer of water electrolysers. Next Hydrogen’s unique cell design architecture supported by 39 patents enables high current density operations and superior dynamic response to…

Presentation

Industrial load flexibility, the US power grid and ammonia

A variable renewable power grid is a new technological regime that involves real time harvesting and low-cost availability of energy resources coupled with storage to meet additional needs. Decarbonization through electrification of end uses formerly met by combustion processes will be a concurrent trend. Taken together, these two changes may make flexibility on the demand side more valuable to the grid and to industrial users. Industry accounted for 26% of US power demand in 2021. Traditionally, industrial processes for producing ammonia and other basic materials have been optimized for a system based on fossil resources, where energy can be called…

Presentation

Dancing with wind solution for the green hydrogen and green ammonia plant

What renewable energy contradicts the existing traditional ammonia synthesis system the most is fluctuating power output. Envision Group strives to solve this problem. “Dancing With Wind Solution” means with the help of integrated control system and management system, Envision is right now designing dynamic system optimization of the ammonia synthesis process. When the wind speed changes, all the downstream processes and systems will change their power input requirements accordingly.

Establishing a Global Market for Ammonia Energy

Thursday, November 17, 2022 8:30 am 10:30 am

Presentation

Ammonia, liquid sustainable energy for future

Hans Vrijenhoef with many years of experience in green ammonia developments will address the topic that ammonia can be used as the carrier of green electricity from Arab world to Europe, Japan , Korea and many other countries, which are lacking natural gas or ammonia production or where ammonia costs are high. Using the green energy, Proton technology enables its clients/ partners to use based on their strategies options for import or export green ammonia, blue ammonia or byproduct ammonia in a safe and environmentally friendly way. After detailed studies and a mutual search for off-takers, Proton offers the skills…

Presentation

Establishing a Global Market

In the introduction to this keynote panel several aspects of the conversion of global ammonia fertilizer and chemical feedstock market into global ammonia energy market will be proposed for discussion. How ammonia may serve as a key driver for energy transition? How world clean energy needs will drive ammonia market growth? How related are ammonia and hydrogen markets? How technology development can affect the market growth? How to balance supply and demand? How existing ammonia trade can help in setting ammonia energy trade? What global infrastructure development needed to support the market? What is the role of governments in creation…