IHI Commits to Ammonia Energy. Big Time.

By Stephen H. Crolius on February 08, 2018

During his presentation at the November 2017 NH3 Energy + Topical Conference, Shogo Onishi of IHI Corporation described the progress made by IHI and Tohoku University in limiting NOx emissions from ammonia-fired gas turbines (AGTs). Regular attendees of the annual NH3 Fuel Conference identify IHI with its work on AGTs since the company also addressed this topic at the 2016 and 2015 events. However, a scan of published materials shows that AGTs are just one aspect of IHI’s activity in the ammonia energy arena. In fact, IHI is also looking at the near-term commercialization of technologies in ammonia-coal co-firing in steam boilers and direct ammonia fuel cells. This level and breadth of commitment to ammonia energy is unique among global capital goods producers.

According to its website, IHI is the corporate descendant of Japan’s first modern shipbuilder. Founded as the Ishikawajima Shipyard in 1853, the company diversified over the next hundred years into heavy machinery manufacturing, bridge building, and plant construction. In 1960 it merged with Harima Shipbuilding & Engineering to create Ishikawajima-Harima Heavy Industries. Today the company is organized into four lines of business: Resource, Energy and Environment; Social Infrastructure and Offshore Facilities; Industrial Systems and General-purpose Machinery; and Aero Engine, Space and Defense. Revenues for the most recent fiscal year were ¥1,486 billion ($13.6 billion). The company has a substantial presence in most of the world’s major economies in the form of Sales and/or Engineering & Construction offices, and/or subsidiaries and joint ventures.

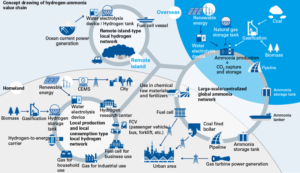

IHI’s Corporate R&D Web pages provide an exceptionally forthcoming description of the company’s R&D strategy. IHI lists only two “Technology Focuses for the Future.” One is the use of information and communications technology to “materialize smart factories, systems, and societies.” The other is to develop “core technologies and product lines for the hydrogen and ammonia value chains to cater for the needs of a low-carbon society.” The subsequent discussion of the hydrogen-ammonia value chain starts with the rationale for a hydrogen-based energy economy and then turns to the role of ammonia:

Hydrogen is less likely [more difficult] to liquefy and likely to make metal fragile; therefore, the high cost to transport and store it has become an issue. As a carrier for efficiently transporting hydrogen, we are focusing on using ammonia (NH3), which is converted from hydrogen.

Ammonia has high hydrogen content per volume and is likely [easier] to liquefy. In addition, ammonia has been distributed as a fertilizer or chemical raw material and its transportation infrastructure has already been developed, providing a big advantage for implementing in society.

Creating Value for the Future: A Future Based on Technologies, IHI website, February 2018

The discussion continues, “To realize a hydrogen society early on with minimal capital investment, we are also focusing on developing technology for using ammonia in various scenarios.” Specifically mentioned are the company’s efforts around ammonia’s use as a fuel for both gas turbines and boilers.

Onishi spoke at the NH3 Energy + Topical Conference on behalf of a team drawn from IHI and the Institute of Fluid Science at Tohoku University. As articulated in a February 2017 Ammonia Energy story, Hideaki Kobayashi, director of the Reacting Flow Laboratory within the Institute, is credited with developing “the world’s first technology for direct combustion of ammonia in a gas turbine.” Consistent with the positive takeaways from Onishi’s talk, IHI confirms that the team has “established a technology for stably burning ammonia while suppressing the production of NOx (nitrogen oxide).” With this success, the thrust of the program appears to be moving from the laboratory to the marketplace, with IHI intending to “accelerate our efforts to commercialize this technology by field-testing power generation by 2-MW class gas turbines.”

The public profile of the company’s activity in coal-ammonia co-firing is more modest than that of its AGT work. A December 2017 Nikkei Sangyo Shimbun story (“Closing point of coal-fired power plant”) stated that “IHI is planning a test to mix 20% ammonia into a coal-fired boiler at Aioi Plant (Aioi City, Hyogo Prefecture) and start a basic design [process with] actual use in 2018.”

The products that will result from IHI’s AGT and coal-ammonia co-firing efforts have obvious fits within the company’s Resource, Energy and Environment business line, in the Gas Turbine and Boiler product categories, respectively.

The public profile of IHI’s ammonia fuel cell program is also modest. The program is a joint undertaking of a multi-party group that includes Kyoto University, Toyota Industries, ceramics manufacturer Noritake, chemical companies Tokuyama, Nippon Shokubai, and Mitsui Chemicals, and IHI.

A near-term goal of the program appears to be a device that can be commercialized for use in residential applications. Residential fuel cells, dubbed “Ene-Farm” units in Japan, have been on the market in the country since the late 2000s. They are fueled with natural gas. In August 2017 Nikkei Sangyo ran a story (“JGC and IHI utilize ammonia for hydrogen power generation”) stating that IHI had “started to commercialize fuel cells using ammonia.” The story says that IHI intends “to prototype a 1 kilowatt class equipment with power generation output, and will conduct a verification test in fiscal 2018. The power generation efficiency aims at the latter half of the 40% level which is comparable to that of residential fuel cells already in practical use,” i.e., ammonia will meet the standard set by natural gas.

At the time of an Ammonia Energy story in May 2017, Panasonic and Toshiba were the primary suppliers of Ene-Farm units. In June 2017, Toshiba announced that it “will end manufacture and sales of ENE-FARM residential fuel cell systems by the end of July 2017.” The direction of causality, if any, between Toshiba’s Ene-Farm exit and IHI’s entrance is not discussed in the Nikkei Sangyo story.

IHI’s participation in the fuel cell collaboration is overseen by the company’s New Products Incubation Center within its Corporate R&D unit. The company’s role will be to manufacture a number of the fuel cell’s components including the cell stack.

As reported in an August 2017 Ammonia Energy story, IHI is a charter member of Japan’s Green Ammonia Consortium.