Report from the European Conference: Ammonia-Fueled Gas Turbines

By Stephen H. Crolius on June 22, 2017

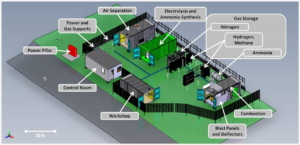

The ammonia-fueled gas turbine (A-GT) seems destined to become one of the key technologies in the sustainable energy economy of the future. Siemens AG, for one, features the A-GT in its vision for “Green Ammonia for Energy Storage and Beyond” and in the demonstration system that the company is building at the Rutherford Appleton Laboratory in the U.K. Last month Dr. Ian Wilkinson, Siemens’ Programme Manager for the demonstration project, spoke about the project’s progress at the 1st European Power to Ammonia® Conference in Rotterdam in The Netherlands. Although he devoted a slide to the A-GT, the detailed perspective came from another presentation at the conference. This one was delivered by Dr. Agustin Valera-Medina, a Senior Lecturer at Cardiff University, one of Siemens’ main green ammonia collaborators.

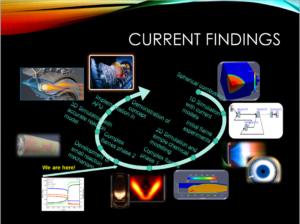

Ammonia Energy has reported previously on A-GT research efforts in Japan, the United States, and Turkey, as well as at Cardiff University. The previous post on the Cardiff work reported on a paper published last summer that described a “reduced mechanism” that facilitates the modeling of the complex chemical reactions that occur when ammonia is burned in a gas turbine. The paper described the success of the reduced mechanism in describing reaction kinetics in a series of ever-more sophisticated simulations (“zero-dimensional”, “one-dimensional”, and “two-dimensional”). This type of modeling allows researchers to design and modify test equipment and to adjust experimental parameters in a way that accelerates progress toward targeted real-world performance.

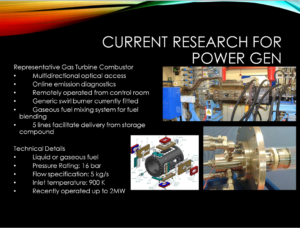

Valera-Medina’s presentation at the European Conference reported on physical experimentation that was enabled by the reduced-mechanism modeling. This involved one of the test rigs at the University’s Gas Turbine Research Centre. This “gas turbine combustor” has a power capacity of up to 2 MW, and is thus more representative of utility-scale machines than the 100 kW-scale units on which most development efforts have operated to this point.

It is well-established that ammonia can be burned in gas turbines. The research at Cardiff and the other institutions with A-GT programs is focused on how to burn it with the greatest efficiency (i.e., substantial conversion of chemical energy into mechanical power that can be turned into electricity) and cleanliness (i.e., minimization of unburned ammonia and combustion byproducts such as NOx).

In the course of their experiments, the Cardiff researchers studied the effects of varying both the equivalence ratio and the inlet temperature. The equivalence ratio speaks to whether the combustion mixture is “lean” (excess oxygen) or “rich” (excess fuel). They also experimented with introducing steam into the combustion mixture. The team was interested both in the absolute value of NOx and unburned ammonia in the exhaust gas, and how that value compared with the prediction from their reduced mechanism model.

Valera-Medina’s presentation included a series of graphs showing that the experimental results were generally consistent with the modeled predictions. The graphs also showed that it is possible to drive NOx content to near-zero levels, albeit at the expense of efficiency. The “best case” that emerged from the experimentation involved the addition of steam to the combustion mixture. It yielded power generation of 40 kW with 247 ppm of unburned ammonia and 75 ppm of NOx. The presentation did not say whether emissions at this level would be obtainable if the machine were run closer to its power capacity.

The Cardiff team is moving toward a prototype gas turbine that can be used in practical applications, such as in a green ammonia energy storage system. Before they get there, Valera-Medina anticipates that they will need two more rounds of modeling and one more round of physical experimentation. The timeline associated with their current funding facility calls for the realization of an “ultra-low NOx GT combustor” by the end of 2020.

Siemens, it should be noted, is one of the largest gas turbine manufacturers in the world. Its Power and Gas Division, whose product portfolio includes “gas turbines, steam turbines, generators to be applied to gas or steam power plants, compressor trains, integrated power plant solutions, and instrumentation and control systems for power generation,” had revenues of €16.5 ($18.3) billion in 2016, according to the company’s annual report.