Ammonia-Fueled Gas Turbine Power Generation

By Ammonia Energy News on February 16, 2017

This article, originally written by Harumi Uenami and published in the February 2016 edition of “JST News,” is republished here courtesy of the Japan Science and Technology Agency, in translation by Ken-ichi Aika, Professor Emeritus of Tokyo University. We have mentioned the gas turbine program at Tohoku University before (in October 2016 and February 2017). Dr. Aika brought this article to our attention because it provides the full story of the technology development.

Hideaki Kobayashi, professor at the Institute of Fluid Science at Tohoku University in Sendai, Japan, has developed the world’s first technology for direct combustion of ammonia in a gas turbine. The advance was made in cooperation with the National Institute of Advanced Industrial Science and Technology (AIST) under a program led by Norihiko Iki.

It has long been known that ammonia is a combustible substance. However, because its flame speed is very slow (only one-fifth that of methane), it is challenging to use as a fuel. But because ammonia burns without emitting carbon dioxide, it has a role to play in a low-carbon society. Kobayashi took on the challenge of combusting ammonia in a stable and efficient process and ultimately succeeded.

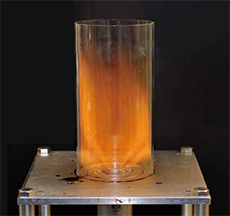

Kobayashi brought to bear his expertise in combustion science, as well as facilities and equipment well-adapted to the study of combustion. He started by applying a swirl flow device that would create a spiral motion of the gas in the combustion chamber. This had the effect of controlling the flow of the ammonia-air mixture and stabilizing the combustion. Kobayashi mounted a glass cylinder or “liner” onto the swirl burner. He said the flame was unstable without the liner at the first stage of the experiment, but when it was added the swirl flow formed both horizontally and vertically. This kept the gas mixed long enough for maintenance of a stable flame. Unburned ammonia could be reduced at the outlet. When supported with the proper equipment, ammonia indeed can burn strongly with a beautiful orange flame as is seen in the photo on the right. It is possible to generate a great deal of heat even in a small burner by increasing the swirl velocity. Nitrogen oxides (NOx) are a byproduct of ammonia combustion, and if emitted cause air pollution and acid rain. A NOx removal system using catalyst technology has already been established, but the future target is to improve the combustion technology so that nitrogen oxides in the flame are minimized.

In August 2014, the team led by Kobayashi and Iki was the first in the world to succeed in using an ammonia-fueled combustion turbine to drive a generator. Their turbine is optimized for ammonia via the use of extra turbine blades that generate a high-pressure, high-temperature fuel mixture. The team is using a system with a maximum power output 50 kW. Initially they were able to achieve a stable power output of 21 kW with a mixture of 30% ammonia and 70% kerosene. By September 2015, they had reached 41.8 kW using a mixture of methane and ammonia. Subsequently they were able to reach this same output power with 100% ammonia.

“We could not supply 100% ammonia in 2014 because we only had a small cylinder (50-kilogram). But now, with a one-ton cylinder, we have large amounts of ammonia available. We set up a facility to supply heat to liquid ammonia held at 8.5 atmospheres so as to evaporate the fuel into the gas turbine.”

The encouraging results raise the possibility of a near-term role for ammonia-fired gas turbines in commercial power generation. However, practical applications of this nature are still some distance off. “The scale of facilities in experimental research for gas turbines is quite different from the gas turbines running in large power plants. The ammonia-fueled turbine used in our tests has an output of 50 kW maximum. This compares with turbines used in practical power plants that range from several tens to several hundred MW. Large power plant gas turbines are fitted with numerous burners and the size of even one burner is several hundred times larger than that used for the experimental unit. It is not realistic to scale up the same combustor structure from 50 kW to several hundred MW all at once. We need to develop equipment for the large scale step by step.”

Kobayashi notes that favorable conditions exist for ammonia industrially, with infrastructure and plant equipment that can be adapted to the use of ammonia. The transportation of ammonia via tank truck is well established and ammonia storage facilities are also available. De-NOx equipment that uses ammonia as a catalyst is already in use in power plants which means that ammonia tanks are already on the premises.

“I don’t envision all current fuels being replaced by ammonia” Kobayashi said. “I think power plants with large tanks and appropriate equipment available can apply ammonia combustion. Homes and cars can apply small fuel cells that use hydrogen. In this way, each can help in the realization of a low-carbon society.”

The first goal is to bring the efficiency of the ammonia gas turbine to the same level as that of a conventional gas turbine, Kobayashi said. And in the near future, ammonia fuel can be used in a gas turbine in commercial power generation.