Ammonia, Hydrogen P2X2P Demonstrations Slated for Europe

By Stephen H. Crolius on May 28, 2020

At this early point in the energy transition, many groups are formulating big-picture concepts for the design of a sustainable energy economy, and many more are developing discrete technologies that will be relevant as the transition advances. The multi-stakeholder H2020 European project known as “FLEXibilize combined cycle power plant through Power-to-X solutions using non-CONventional Fuels” (FLEXnCONFU) is coming from a different direction. Its premise is that construction of a bridge to the future should start now, and should be anchored in aspects of the current energy system that are likely to endure over the long-term.

Combined cycle power plants became a mainstay generating technology when the cost of energy from natural gas fell below that of energy from coal. The name derives from the practice of combining a gas turbine (which operates on the Brayton cycle) with a steam turbine (which operates on the Rankine cycle). The gas turbine burns natural gas, producing hot exhaust as well as rotary motion that drives a generator. The hot exhaust is used to produce steam which is fed into the steam turbine. Combined cycle plants can achieve energy efficiencies greater than 60%, vs. efficiencies of about 40% for open cycle plants.

FLEXnCONFU is focused on the evolutionary steps that combined cycle plants could take as society looks increasingly to renewable generation as a preferred source of electricity. As described by project coordinator Alessandra Cuneo in an interview with ETN News, “The FLEXnCONFU project aims to respond to today’s challenge for fossil fuel power plants, which have to shift their role from providing base-load power to providing fluctuating back-up power.”

According to Cuneo, “the main goal of FLEXnCONFU is to develop and demonstrate in a real combined cycle (CC) plant an innovative, economically viable and replicable power-to-X-to-power solution that enables the operation and design of an integrated power plant layout to untap CC plants’ flexibility.”

One key phrase in this formulation is “power-to-X-to-power” (P2X2P), i.e., the much-discussed idea that an excess of electricity beyond real-time demand, mainly generated by intermittent renewables, can be stored economically in the form of a chemical such as hydrogen or ammonia – and then turned back into electricity when renewable output falls below demand.

Another key phrase is “untap CC plants’ flexibility.” In the design of the current electric grid, which casts different types of generating plants in “base load,” “shoulder,” and “peak” supply roles, combined cycle plants are almost always considered “base load” because of their favorable economics and inflexible operating characteristics. The FLEXnCONFU concept, envisions combined cycle plants no longer as the star athletes that anchor the system but instead as team players who must cooperate with the front-line renewable generating assets.

Project activities will be conducted at three sites. The hydrogen version of the P2X2P concept will be demonstrated at Energias de Portugal’s Ribatejo power plant. Here the hydrogen will be produced in a 1 MW electrolyzer bank and consumed via low-concentration blending into the plant’s natural gas feed. The ammonia version of the P2X2P system will be demonstrated at laboratory scale at the University of Genoa in Italy. Here the hydrogen produced by a 30-50 kW electrolyzer will be fed to a small-scale ammonia reactor that will feature both mild temperature and pressure (<300˚C and <35 bar, respectively). The back half of the P2X2P roundtrip will be demonstrated via combustion of ammonia in a 100 kW micro gas turbine whose combustor will be modified for the purpose. Finally, the combustion dynamics of hydrogen and ammonia in gas turbines will be studied at Cardiff University in the United Kingdom.

In parallel with these demonstrations, the research team will start to develop the plant-level and grid-level control systems that will allow “efficient integration of power-to-X components.”

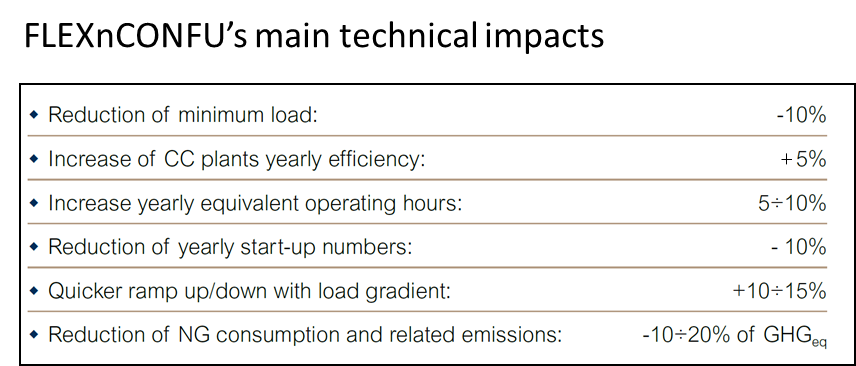

The ETN News interview includes a table of benefits that P2X2P technology could bring to combined cycle plants. The addition of the electrolyzers as a discretionary load could increase “yearly equivalent operating hours” by 5-10%; reduce “yearly start-up numbers” (the amount of time a combined cycle system spends starting up after a shutdown) by 10%; and increase “yearly efficiency” by 5%. The control system enhancements could reduce the system’s “minimum load” (the rate of generation below which the turbines cease to function), and shorten the time needed to transition from one level of output to another (ramp-up and ramp-down) by 10-15%. And overall, the team envisions that the integration of a P2X2P system based on hydrogen or ammonia into an existing natural gas combined cycle plant could reduce greenhouse gas emissions by 10-20%.

The heft of the FLEXnCONFU project can be seen as much in the size and make-up of its team as in the ambition of its objectives. A total of 21 organizations drawn from ten European countries represent “the entire supply chain of the centralised power generation,” according to a press release issued by the project. Included among the “industrial and SME [small- and medium-sized enterprise] partners” are Ammonia Energy Association members Proton Ventures, Hydrogenics, and Engie (represented by the company’s technical consultancy Laborelec). Project partner ETN Global, the association of the turbomachinery industry, will lead a FLEXnCONFU Users Group, “consisting of end-user organisations and experts in the field,” with the goal of promoting awareness of project results and “replicability in the market.”

Project work started on April 1, 2020 and will continue for four years. Almost 80% of the €12.6 million (USD $13.8 million) budget is being funded by the European Union’s Horizon 2020 R&D program. The balance will come from the project participants.