Ammonia solutions for the UK construction industry

By Julian Atchison on July 19, 2022

Replacing red diesel

The UK government will fund a new project from engine developers MAHLE Powertrain and partners Clean Air Power and the University of Nottingham. The trio will demonstrate decarbonisation of heavy duty engines using ammonia and hydrogen fuel (or a blend of the two), based on MAHLE’s existing technology and with Clean Air Power to develop a fuel injector.

“Red diesel” or Rebated diesel is used by off-road industries in the UK, and is taxed at a much lower rate. This government funding round will support projects developing replacement fuels for red diesel, whose use is now heavily restricted after new regulations came into effect this April. This poses a particular challenge for the construction industry, which currently uses 56% of all red diesel in the UK.

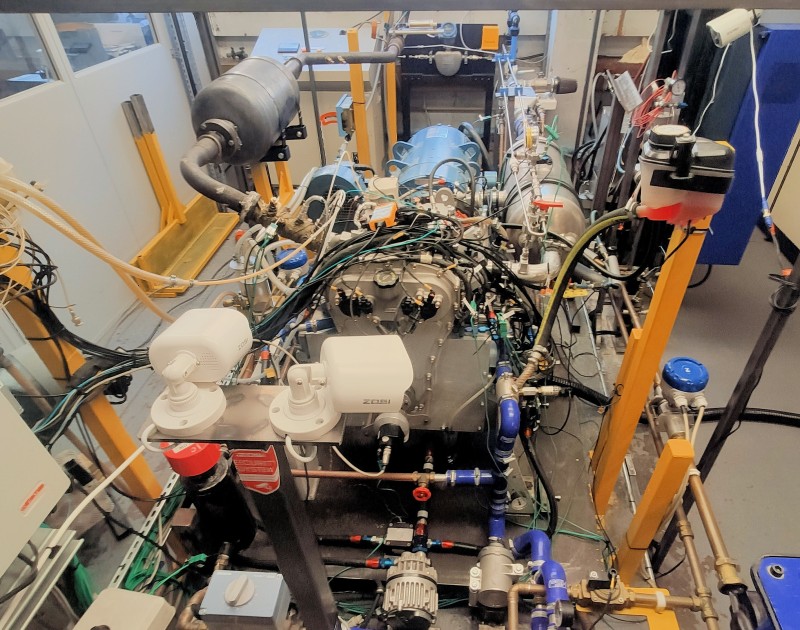

The research focuses on two approaches. The first is a near-term, retro-fit, dual-fuel arrangement being tested on a six-cylinder turbodiesel genset engine. Additional injectors added to the air intake introduce ammonia as the main source of energy.

The second approach is being developed using MAHLE’s own single-cylinder engine and uses MAHLE Jet Ignition® (MJI) – a highly innovative form of pre-chamber ignition – replacing the traditional spark plug to ignite the ammonia, eliminating the need for a fossil-fuel ignition source.

MAHLE’s Jet Ignition technology consists of a small chamber in the cylinder head that, once ignited, forces the resulting hot gas through small orifices into the main combustion chamber as a series of jets that quickly and uniformly ignite the remaining mixture.Technical details of the research project from MAHLE’s official press release, 31 May 2022

The technology ensures super-clean, efficient combustion throughout the chamber with little or no pollutants such as nitrogen oxides being produced. The combustion speed increase enabled by MJI deals with one of the challenges of using ammonia which typically burns at a comparatively slow rate.

MAHLE, Fortescue and Liberherr

Fortescue Future Industries is already involved in the decarbonisation of the UK construction industry. In October last year, JC Bamford Excavators signed an agreement to purchase 10% of FFI’s annual renewable hydrogen production (~1.5 million tonnes per year by 2030). JCB Chairman Lord Jo Bamford is also a founder of Ryze Hydrogen, which is developing the UK’s first series of renewable hydrogen production plants.

It’s fine having an engine powered by green hydrogen, but no good if customers can’t get green hydrogen to fuel their machines. This is a major advance on the road towards making green hydrogen a viable solution.

JCB Chairman Lord Jo Bamford in FFI’s official press release, 31 Oct 2022

FFI is also partnered with German heavy vehicle manufacturer Liebherr. Liberherr will deliver a fleet of 120 heavy haul trucks capable of being integrated with either a battery system (currently under development by FFI and Williams Advanced Engineering), or hydrogen-powered fuel cell technology. FFI aims to have the first vehicles operating in Australia by 2025.

The loop closes with a final announcement from October 2021, where Liebherr and MAHLE signed a formula agreement to jointly develop hydrogen-powered heavy engines. The intended applications for these engines? Excavators, track vehicles, and wheeled loaders: exactly the “off-highway” scenarios currently powered by red diesel in the UK.

Ammonia fuel cells for construction sites

And from engines to fuel cells, we shouldn’t forget AFC Energy are currently rolling out off-grid, ammonia-powered gensets in the UK and European construction industry. In April this year AFC launched its Power Tower, one demonstration unit of which will be leased & deployed by Keltbray on a London construction site (and another by Acciona in Madrid).