Amon Maritime unveils ammonia-powered, offshore platform supply vessel

By Julian Atchison on November 11, 2022

“Carbon free workhorse for the North Sea”

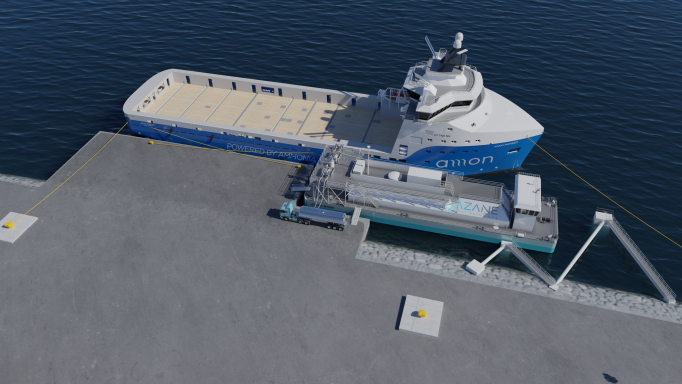

Amon Maritime has launched a new subsidiary – Amon Offshore – which will “build, own and operate” a fleet of ammonia-powered platform supply vessels, to operate off Norway’s coast. The PSV fleet will be managed by Amon subsidiary UIa Ship Management, and will service oil platforms in the North Sea. Ammonia bunker fuel will be supplied by Yara Clean Ammonia, and delivered from supply bases by Azane Fuel Solutions’ new bunker barge design.

This is the next generation. We are combining new technologies with future requirements, enabling capabilities only available for newbuildings. Our vessels will be carbon free, future proof, and holistically designed for ammonia fuel from the ground up.

Amon Maritime Founder & CEO André Risholm in his organisation’s official press release, 31 Oct 2022

The new design will be in full compliance with the Norwegian government’s requirements that all PSVs on the Norwegian Continental Shelf must be zero emissions by 2030. Amon estimates this will require eighty new builds or retrofits to existing vessels in the second half of this decade, and the aim is to have the first ammonia-powered PSV on the water by 2025. The PSV design has already received AiP for ammonia notation from DNV, and in May this year Norwegian Maritime Authorities issued preliminary flag approval.

Two more ammonia-powered AiPs in China

Lloyd’s Register has awarded Nantong COSCO KHI Ship Engineering Co. Ltd. (NACKS) AiP for an ammonia-powered, 16,000 TEU container ship. The pair have been working alongside Hudong Heavy Machinery Co. Ltd. (HHM) since early 2021 on a HAZID assessment of ammonia fuel, as well as design features of the vessel to mitigate risk on board.

And, RINA has awarded China State Shipbuilding Corporation AiP for a 50,000 tonne, mid-range oil/chemical tanker (Chinese language). In its announcement, CSSC indicates that on-deck fuel tanks are a feature of the new design, and that risk & hazard mitigation systems are “relatively easy” to implement on mid-range oil tankers.