Bunker Ammonia: momentum toward a “sustainable and future-proof” maritime fuel

By Trevor Brown on June 15, 2017

The maritime industry is beginning to show significant interest in using ammonia as a sustainable “bunker fuel,” an alternative to the highly polluting heavy fuel oil (HFO) currently used in ships across the world.

In recent months, a firm of naval architects and a new maritime think tank have both been evaluating ammonia as a fuel. This includes a road map for future research, and collaborations for a demonstration project that will allow them to design and build a freight ship “Powered by NH3.”

As I wrote in my first article on bunker ammonia, the maritime industry is searching for an alternative fuel because, even with efficiency improvements and battery storage, it cannot meet its sustainability targets. The industry wants to identify and deploy a carbon-free liquid fuel to keep the International Maritime Organization’s (IMO) ongoing commitment to the Paris Agreement.

This anticipated shortfall in meeting decarbonization targets has led to the establishment in the Netherlands of a “Maritime Think Tank,” which has evaluated ammonia fuel in its recent publication, Ship 2040: Pioneers of the Maritime Sector. This industry-focused pamphlet presents “a collection of ideas in an effort to develop a sustainable vessel together by the year 2040.”

Early 2016, we observed that a number of good projects were already running, or were even finalized. However, we could not manage to present a sustainable ship in 2040 that would meet the ambitions stated. That is why a Maritime Think Tank was established … We will start with ideas and further input from the Dutch maritime sector, but plan to go fully international as well.

Mieke Bakker-Mantjes, Sector Manager Maritime International CSR, Ship 2040, 2017

Ship 2040 includes 14 articles in the categories of Design, Materials, Disassembly, Ecology, and Propulsion & Energy. In the Energy section, along with technical evaluations entitled “The maritime sector somewhat lags behind the automotive industry,” and “Maritime sector needs more courage and guts,” is a forceful article demonstrating that “ammonia as a clean renewable fuel is a viable and promising idea.”

Producing ammonia as a carbon-free bunker fuel

As explained by naval architect Niels de Vries from C-Job Naval Architects, the first step is to create a clean fuel supply: producing ammonia using renewable power instead of fossil fuels.

Ammonia as a fuel is sustainable and future-proof. One produces ammonia using nitrogen and hydrogen. Nitrogen is gained through an air separation process; 78% of it is available in the atmosphere. Hydrogen is gained through electrolysis of demineralised water and we have an abundance of water on earth. Both processes can operate on electricity … after which one can produce ammonia using the components nitrogen and hydrogen applying the Haber-Bosch way of processing.

Niels de Vries, C-Job Naval Architects, Ship 2040, 2017

C-Job is by no means the only industry entity exploring the use of ammonia as a bunker fuel. As I reported here in March 2017, University Marine Advisory Services (UMAS) published a detailed evaluation of different pathways for the shipping sector’s decarbonization, as part of an ongoing project for the Danish Shipowners Association. Its report, Navigating Decarbonisation, published in February 2017, concluded that carbon-free liquid fuels would have a clear role from at least 2030 onwards.

This week, its authors provided a timely and encouraging update:

Whilst ammonia is not explicitly modelled in this work, the study’s outcome on the potential significance of liquid hydrogen, for which ammonia can be thought of as an alternative storage medium, shows the importance of research into non-fossil fuels for this sector. For this reason we are working on new scenarios that would enable us to consider how ammonia might compete with other low/zero carbon fuels, and hope to publish this later this year.

Carlo Raucci, corresponding author of Navigating Decarbonisation, June 2017

Fuel comparisons: HFO, Hydrogen, Ammonia

Neither hydrogen nor ammonia contain any carbon, whereas heavy fuel oil (HFO) is one of the most polluting fuels available. Beyond carbon, HFO also contains high levels of sulphur, causing dangerous SOx (sulphur oxide) emissons on a global scale. So, while HFO’s carbon emissions are hugely important – amounting to roughly 1 gigaton per year, or 2.33% of global carbon emissions – it may ultimately be the sulphur emissions that force the industry to begin the switch to clean bunker fuels.

The IMO recently decided to enforce a reduction in the sulphur content of maritime fuels, setting a stringent maximum of 0.5%, from the maximum of 3.5% today, to be in place by the beginning of 2020. The extent of this reduction and the speed at which it is being imposed will have profound market implications. In other words, reducing sulphur emissions may increase the costs of HFO to the extent that ammonia becomes economically competitive.

Ship 2040 acknowledges that energy density is the downside for ammonia – but only when compared to HFO: when compared to other carbon-free fuels, ammonia is the most energy-dense fuel available.

The big advantage of ammonia is the higher energy density per cubic metre, compared with pure hydrogen. De Vries adds: “Pure hydrogen in liquid and in gaseous substances have a much lower energy density per cubic metre. Liquid ammonia can be stored at a much more acceptable temperature and pressure (-33.4 °C at 1 Bar), compared with pure hydrogen [-252.9 °C]. It all makes ammonia as an energy carrier quite interesting …

“An additional challenge of ammonia is to consider that the energy density per cubic metres is indeed higher than pure hydrogen but significantly lower than Heavy Fuel Oil (HFO). In practice, this implicates that ammonia for a similar amount of energy requires 2.5 times more space as HFO and that it weighs 1.9 times more. This aspect should be taken into account when designing a vessel.”

Niels de Vries, C-Job Naval Architects, Ship 2040, 2017

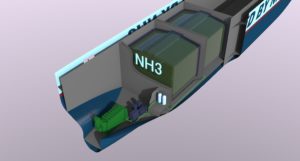

C-Job has now produced detailed renderings of maritime ammonia fuel tank designs.

These designs take into account ammonia’s energy density, based on a higher heating value (HHV) of 22.5 MJ/kg and liquid density of 680 kg/m3, as well as its physical properties. The fuel tanks would store liquid ammonia either refrigerated (at ambient pressure and -33.4 °C) or compressed (at 10 Bar and room temperature). These designs are informed by commercial ammonia storage tanks, which provide cheap, bulk storage options to a mature and highly regulated industry with a good safety record.

C-Job’s maritime ammonia fuel tank designs also allow for “safety margins,” from the side and bottom, comparable to those defined in the existing regulations for LNG- (liquified natural gas) fueled ships.

These specifications require significantly less space than would be required for hydrogen, either as a compressed gas or a liquid. C-Job concludes that ammonia fuel tanks would be far more stable, acceptable, and practical than hydrogen fuel tanks, given the very high pressures or extremely low temperatures required for on-board hydrogen storage.

Using ammonia as a maritime propulsion fuel

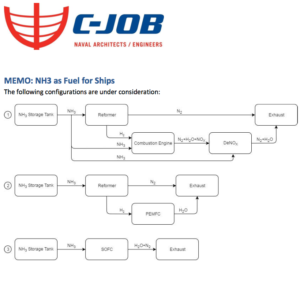

C-Job is evaluating three configurations for ammonia-fueled propulsion systems. The first and most easily adopted, because of the simplicity of conversion and low cost of deployment, uses “a dedicated combustion engine.” To overcome the difficulty of burning pure ammonia, part of the fuel stream is “cracked” in an on-board reformer, to provide a small amount of hydrogen fuel, which burns easily and thus acts as a combustion promoter, allowing the ammonia to combust more easily.

The configuration requires a catalyst that partly cracks [ammonia into] nitrogen and hydrogen. As a result, the hydrogen will combust, through which the remaining ammonia will combust as well. Industrial research has shown that it can be done using 3% hydrogen and 97% ammonia. Consequently, ammonia will be combusted completely, thus becoming nitrogen and water. NOx emissions can be suppressed by a proper design and operation of the combustion engine.

Niels de Vries, C-Job Naval Architects, Ship 2040, 2017

C-Job is evaluating two other fuel configurations, both of which use fuel cells. In one, a proton exchange membrane fuel cell (PEMFC), the ammonia will be completely cracked into a pure hydrogen fuel stream. In the other, a solid-oxide fuel cell (SOFC), ammonia is used as a direct fuel with no conversion into hydrogen – this configuration therefore avoids the cost a reformer.

In all these fuel configurations, the only emissions will be pure nitrogen (N2) and water vapor (H2O). Even in the traditional engine, the NOx emissions from combustion can be avoided by proper engine design and operation, combined with a traditional DeNOx unit, which would consume a tiny amount of the ammonia as its own DeNOx agent.

The safety of using ammonia as a bunker fuel

As Ship 2040 makes clear, ammonia is a hazardous chemical and any fuel system design must take into account its risk profile.

Indeed, ammonia is toxic, but bear in mind that there is more [than a] hundred years of experience in usage, for instance in the fertilizer industry. There is quite some knowledge in the field of safety standards for storage and use. On top of that, ammonia is transported with ships worldwide for decades. Yet, safety issues onboard ship should be developed even further. Training crew how to handle ammonia as a fuel is one of them.

Niels de Vries, C-Job Naval Architects, Ship 2040, 2017

The safety considerations that C-Job has examined go beyond simple human health concerns to include environmental safety – highly important, given the potential for ocean spillage. As C-Job acknowledges, a spillage would of course be dangerous for the direct environment. But, unlike an oil spill that can cause decades of irreparable damage, ammonia is biodegradable: it quickly becomes so diluted that it no longer poses any danger to wildlife, and what remains is easily and harmlessly metabolized by living organisms.

Additionally, C-Job’s analysis notes that toxicity is not unique to ammonia, but is shared by a range of existing and alternative fuels, notably methanol. The toxicity of ammonia is simply one of many risk factors that must be respected and reflected in engineering design and operational best practices. This is no different from how we currently manage other risks, like the flammability of gasoline or the explosiveness of hydrogen or LNG.

For more information on the project underway at C-Job Naval Architects, or to initiate collaboration, contact Niels de Vries, Naval Architect, at n.devries@c-job.eu.

C-Job contributed to the @MVO_NL 'Pioneers' booklet stating #Ammonia as an alternative #fuel for the 'Ship of 2040' #hydrogen #futureproof pic.twitter.com/E1vsrzzV7Y

— C-Job Naval Architects (@CJobNA) April 24, 2017