Electrolyser scale-up news: May 2022

By Julian Atchison on May 05, 2022

Novel technologies

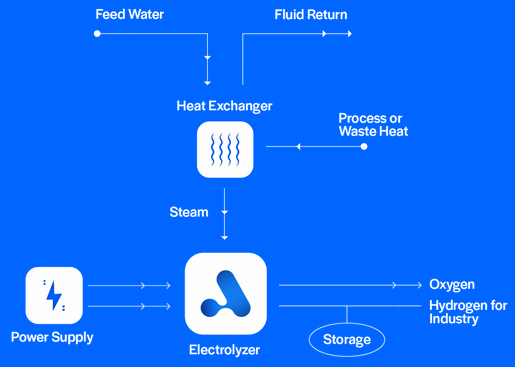

US-based Advanced Ionics recently launched its new solid-oxide electrolysis technology. The Symbiotic™ electrolyser requires 35kWh of electricity to produce one kilogram of hydrogen, less than top-range alkaline or PEM machines which operate at around 50kWh/kgH2. To run at full efficiency, the Symbiotic™ electrolyser requires process or waste heat (>150°C), hence Advanced Ionics are targeting industrial settings for deployment.

Most of heavy industry [that uses hydrogen] — 90%-plus — has waste heat — petrochemicals, ammonia, in the future green steel…Other applications like methanol, glass manufacturing, just about every single thing that uses hydrogen has waste heat in one form or another. Sometimes it’s low-grade, sometimes it’s high-grade. So we’re really the ideal solution for those processes.

Advanced Ionics Founder Chad Mason quoted in ‘Cheaper green hydrogen’ | US start-up’s novel low-cost electrolyser promises 30% more bang per buck, Recharge News 28 Apr 2022 (author Leigh Collins)

Funding

UK-based ITM Power closed a successful, £250m share issue round last November to accelerate expansion. A total manufacturing capacity of 5 GW worth of electrolyser units per year is being targeted: the existing 1 GW factory in Sheffield, a second 1.5 GW factory at a nearby site, and then a 2.5 GW overseas factory (with all three fully operational by the end of 2024).

Battolyser Systems has been awarded €250,000 by the Dutch government that will help finance industrial testing of its integrated battery/electrolyser technologies. Battolyser hopes that successful trials will encourage a commercial partner to invest in a deployment of a demonstration-sized project in 2023 (somewhere between “0.5 to a few MWh/MW”).

In an effort to prepare for industrial production of hydrogen at a gigawatt scale, the German government has granted €60 million to the H2Giga project, to be led by Sunfire. From this larger pool, €33 million will go towards establishing manufacturing processes for Sunfire’s solid-oxide electrolysis cell technologies. The other €27 million will accelerate gigawatt-scale production of pressurised alkaline electrolysers.

Expanding manufacturing capacity

Canada-based Hydrogen Optimized will construct a 5 GW manufacturing facility in Texas. The facility will be purpose-built to supply the planned Hydrogen City, with developers Green Hydrogen International indicating they intend to purchase the entire output of RuggedCell units from the new facility for the first ten years of production.

Nel’s Herøya electrolyser manufacturing facility officially opened in April. Already, Nel have set their sights on an expansion of the 500 MW facility to 2 GW, and a total manufacturing target of 10 GW across multiple facilities by 2025.

Cummins and Sinopec have launched a joint-venture for a PEM electrolyser manufacturing plant in Guangdong Province, China. The 500 MW facility will be completed in 2023, with expansion plans to add an additional gigawatt of manufacturing capacity every year for five years past that date. Sinopec is one of China’s largest hydrogen producers (14% of the national total in 2021), and is seeking to move away from conventional, fossil-based hydrogen production pathways.