Emission performance of ammonia-fueled, four-stroke marine engines

By Kevin Rouwenhorst on June 03, 2025

Click to expand. The ammonia-fueled maritime propulsion landscape, with four-stroke engines on the right. Source: Ammonia Energy Association.

In the lead up to its historic 83rd meeting this April, the IMO’s MEPC (Marine Environment Protection Committee) published a “Review of current literature on tank-to-wake nitrous oxide emissions from ammonia-fueled engines”. The literature review is intended to assist MEPC member states and GESAMP (the IMO body working on LCA guidelines for zero and near-zero marine fuels) to prepare and assess proposals for default emission factors.

Until recently, experimental data regarding emissions from ammonia-fueled, four-stroke engines was mostly based on small-scale laboratory research engines, not necessarily representative of conditions in full-scale engines.

Previously, we reported on the available data for emission performance of ammonia-fueled, two-stroke marine engines. Now, recent public announcements from engine manufacturers allows us to better understand and anticipate the emission performance of ammonia-fueled four-stroke engines. Promising results from full-scale engine testing gives us confidence that nitrogen oxides and nitrous oxide emissions can be mitigated or eliminated altogether, paving the way for deployment onboard operating vessels. Ammonia slip is a key consideration for four-stroke engines, requiring catalytic treatment of the engine exhaust.

Overall performance of ammonia-fueled engines in testing

Here, we explore recent full-scale testing results from engine vendors IHI and Wärtsilä. These results indicate that ammonia-fueled four-stroke engines will be compliant with IMO Tier III requirements when a DeNOX system is utilized. In November 21st 2024, IHI already reported 58 hours of operational engine experience using ammonia fuel onboard NYK’s Sakigake tugboat.

Ammonia as fuel represents an immediate benefit in case of SOX emissions: depending on the pilot fuel used (and in what amount), sulphur-based emissions are reduced to near-zero, and in some cases eliminated completely. Ammonia-fueled engines will also be “overcompliant” with the CO2-equivalent emission thresholds set at MEPC 83.

Both IHI and Wärtsilä base their ammonia-fueled four-stroke engines on LNG-fueled four-stroke engines. The energy efficiencies of LNG and ammonia fuel operations are reported to be similar, based on the low-pressure Otto cycle concept.

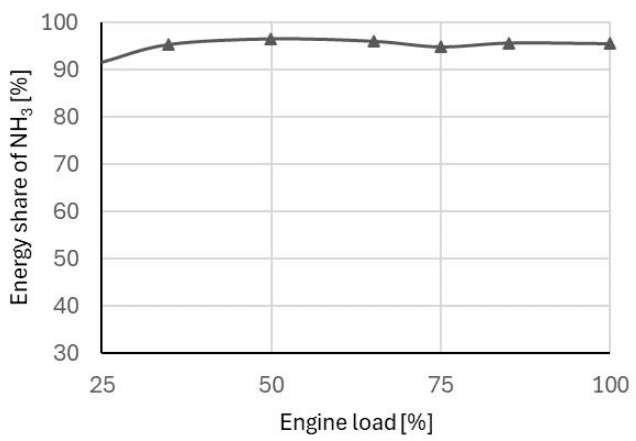

Click to expand. Ammonia share for Wärtsilä’s four-stroke test engine. Fig 6 from Ammonia-powered future: introducing Wärtsilä 25 (presented at the 31st CIMAC World Congress 2025).

The first ammonia engines are dual fuel engines, able to operate in a diesel mode with the same (or better) operational performance as conventional, fossil-fueled engines. Operating in “ammonia mode”, these engines will use around 95% ammonia as a fuel on an energy basis at full load, supplemented with 5% pilot fuel like diesel. At 25% engine load, around 91% ammonia is used, with 9% share of diesel.

Inspections of the engines after fueling with ammonia for 300 hours (out of 600 hours engine testing) at IHI indicates no nitriding of the metals in the engine components. Also, no ammonia leakage has been detected from the equipment during operation and after shutdown. The Wärtsilä 25 ammonia engine is designed according to gas-safe principles, based on their LNG dual-fuel engine, implying that single failure cannot cause ammonia fuel leak into the engine room, and a double-wall piping is used to and from the engine.

Nitrous oxide emissions (N2O)

Nitrous oxide, or N2O, is a potent greenhouse gas, with a global warming potential (GWP) around 273 times that of CO2 on a 100 year basis. Minimizing N2O emissions from ammonia-fueled engines is therefore paramount, as highlighted in the MEPC review.

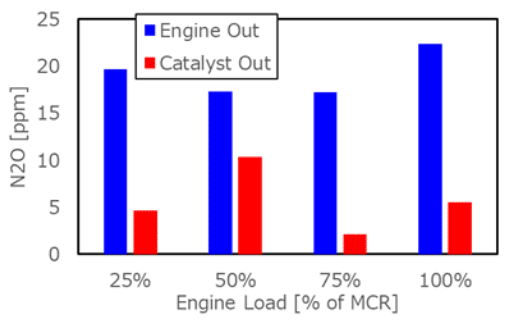

Click to expand. Nitrous oxide emissions from IHI’s test engine, at the engine exit (blue), and after the catalyst (red). Fig 15 from Development of an ammonia-fueled engine (28ADF) for future marine industries (presented at the 31st CIMAC World Congress 2025).

IHI indicates that untreated nitrous oxide emissions from its test engines are around 20 ppm for various engine loads. Emission reduction is possible with a catalyst, reducing emissions somewhere in the range 2-10 ppm. Accounting for the diesel pilot fuel, this results in greenhouse gas (GHG) emission reductions up to over 90% versus diesel mode. Similarly, Wärtsilä indicates that an ammonia-fueled engine with ammonia fuel representing 95% of the energy share achieves up to 90% percent greenhouse gas (GHG) emission reductions compared to equivalent diesel engines.

Operational data from NYK’s Sakigake with IHI’s four-stroke engines indicates that a greenhouse gas (GHG) emission reduction of 94% is achievable using around 95% ammonia fuel. Note that this includes the catalyst after-treatment to further reduce N2O emissions after the engine. Overall, this results in at most 1% CO2-equivalent of an engine operated at full load (less than 1 g-CO2e/MJ) from ammonia-derived N2O emissions, with the remaining 5% of CO2 emissions from the 5% diesel pilot fuel.

Nitrogen oxide emissions (NOX)

Nitrogen oxides, or NOX, is a combination term for the species nitric oxide (NO) and nitrogen dioxide (NO2). Nitrogen oxides contribute to the formation of acid rain and smog, while also affecting the ozone layer. NOX emissions have long been regulated across various industries and jurisdictions, and the IMO first set limits for nitrogen oxide emissions in the maritime sector in 1997 (Tier I). In 2008, the current three tier compliance system was adopted, with IMO Tier II emission limits generally applicable, and more stringent IMO Tier III limits applied to NECAs (NOX Emission Control Areas).

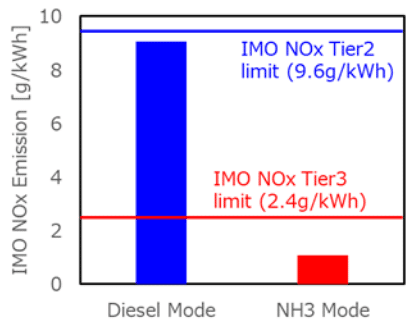

Click to expand. Nitrogen oxide emissions from IHI’s test engine, after the catalyst. Fig 14 from Development of an ammonia-fueled engine (28ADF) for future marine industries (presented at the 31st CIMAC World Congress 2025).

Four-stroke engines require a DeNOX system (a catalyst) to reduce emissions to either IMO Tier II or IMO Tier III NOX limits. Recent testing results indicate lower nitrogen oxides emissions for “ammonia mode” compared to “diesel mode”. IHI’s testing results indicate that its ammonia-fueled four-stroke engine is compliant with IMO Tier III NOX limits in “ammonia mode”, while only being compliant with IMO Tier II NOX limits in “diesel mode”.

Note that this is different from ammonia-fueled two-stroke engines, which are compliant with IMO Tier II without a DeNOX system, and to be compliant with IMO Tier III with a DeNOX system.

Ammonia slip

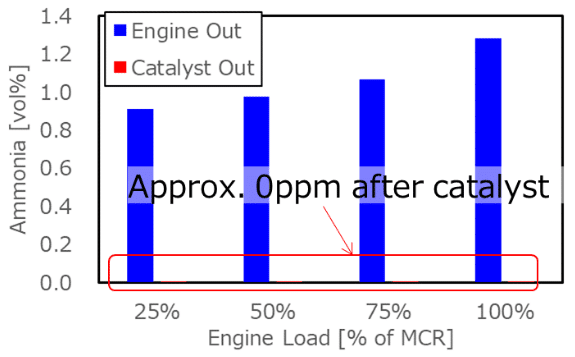

Click to expand. Ammonia slip from IHI’s test engine, before and after catalyst treatment. Fig 13 from Development of an ammonia-fueled engine (28ADF) for future marine industries (presented at the 31st CIMAC World Congress 2025).

Owing to the design of the four-stroke engine, fuel slip is a key issue. LNG-fueled four-stroke engines are known to suffer from methane slip (especially at reduced engine loads) causing significant greenhouse gas (GHG) emissions. Similarly, fuel slip exists in ammonia-fueled four-stroke engines. The ammonia concentration in the engine outlet is around 10,000 ppm (1 vol.%) according to IHI, with a catalyst in the exhaust pipe then reducing ammonia emissions to “virtually zero”. For reference, ammonia slip from ammonia-fueled two-stroke engines is typically below 10 ppm, which is achieved via optimized operational settings and after-treatment.

Conversion of ammonia in the engine exhaust is critical, as it eliminates the risk of potentially unsafe ammonia concentrations exiting the engine via exhaust or leaks. For context, the alarm thresholds set for ammonia leakage in the IMO Interim Guidelines for ammonia-fueled vessels are 25 ppm in enclosed spaces, and 110 ppm in secondary enclosures.

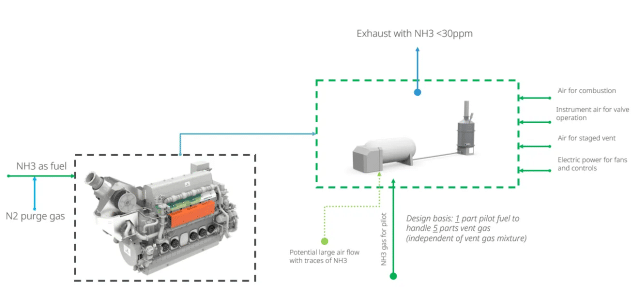

To eliminate risk, release mitigation systems are critical for safe operations of ammonia-fueled four-stroke engines. In 2023, Wärtsilä unveiled WARMS, the Wärtsilä Ammonia Release Mitigation System. WARMS is a system designed for accurate and continuous monitoring of ammonia leaks onboard an ammonia-fueled vessel. WARMS features a staged and controlled combustion process to mitigate leaks, avoiding the need for venting pure ammonia to the atmosphere, or collecting and diluting before disposal. Wärtsilä reports emissions from the system are nitrogen and water, with ammonia slip below 30 ppm (typically below 10 ppm, actual slip was 0 ppm in most testing cases).

Alternative engine concepts for reduced emission profiles

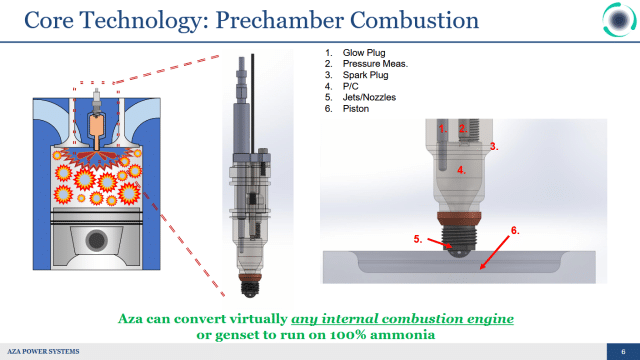

Click to expand. Pre-chamber turbulent jet ignition, an alternative engine concept for reducing exhaust emissions when using ammonia fuel. From Seamus Kane, Carbon-free ammonia combustion technologies (Nov 2024).

Alternative engine concepts are also under development, aiming for reduced emission profiles at the engine exhaust. For example, Azane Power uses pre-chamber combustion turbulent jet ignition, rather than compression ignition used in conventional setups. Aza Power claims emissions are reduced, with low nitrous oxide emissions (<100 ppm), as well as minimal nitrogen oxide emissions and ammonia slip. Rather than dual-fuel operations, Aza Power aims to use 100% ammonia in its engines operating via pre-chamber combustion turbulent jet ignition.