Marine ammonia combustion engines under development in the UK

By Julian Atchison on February 14, 2024

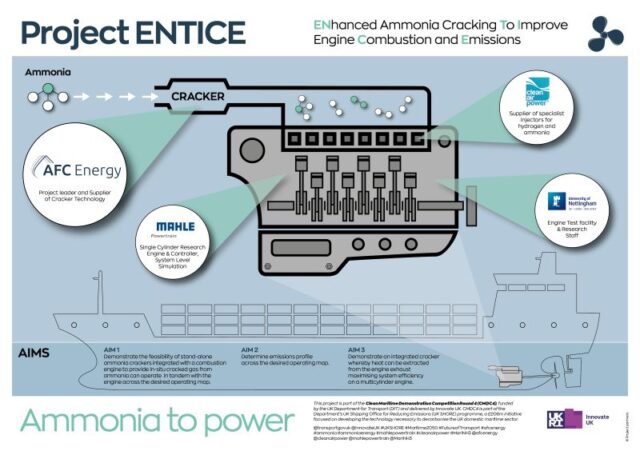

AFC Energy, MAHLE, University of Nottingham, Clean Air Power awarded funding

Click to learn more. Project ENTICE, led by AFC Energy, MAHLE, University of Nottingham and Clean Air Power will demonstrate a marine ammonia combustion engine in the UK. Source: AFC Energy.

The quartet will receive £676,500 from Innovate UK to demonstrate the feasibility of ammonia combustion engines in the marine sector, based on the integration of AFC Energy’s ammonia cracking technology. Based at the University of Nottingham’s engine test facility, a single-cylinder research engine provided by MAHLE will be integrated with ammonia-capable injectors from Clean Air Power and AFC’s cracking technology. From a single-source ammonia fuel feed, the cracking unit will produce an ammonia-hydrogen fuel mixture. After proof-of-concept in 2025, the consortium aims to demonstrate an integration of the cracker with waste heat from the engine, as well as scaling-up to a multi-cylinder design.

Builds on prior R&D program

MAHLE, the University of Nottingham and Clean Air Power recently concluded an R&D program exploring ammonia combustion engines for the off-road construction industry. Key findings from the program were published in the Johnson Matthey Technology Review. Full ammonia combustion was stable at low engine speeds and low-to-moderate engine loads, but some pilot gasoline fuel is needed outside those operating conditions and for start-up. Compared to gasoline combustion, engine performance was more thermally efficient (up to 40%). Comparing pure ammonia and pure gasoline operation, NOx was reduced by ~60% when switching to ammonia, as it is associated with longer and cooler combustion. The researchers noted that pure ammonia combustion resulted in a large increase in ammonia slip, which can be treated by a wide range of proven, commercially mature technologies.