A Deep Dive into SIP “Energy Carriers” Ammonia Combustion Research

By Bunro Shiozawa on September 23, 2020

Editor’s note: Bunro Shiozawa is a Senior Associate at Sumitomo Chemical Company. He has played a unique role in building the case for ammonia as a hydrogen carrier, serving from 2014 to 2018 as Deputy Program Director of Japan’s SIP “Energy Carriers” initiative. Over the last year he has published a ten-part series of articles that describe and reflect on the work done by him and his colleagues, and its impacts in Japan and beyond. The first half of Part 4 of the series is posted in Shiozawa’s English translation below. The second half will be posted in the near future.

Ammonia as a combustible fuel comes with two challenges: 1) can it be burned in a stable manner? and 2) can it burned in a way that does not result in unacceptable levels of NOX emissions? In this article, I will explain how these concerns were addressed by scientific studies and R&D supported by the SIP “Energy Carriers” initiative, and how the prospects of NH3 as a CO2-free fuel were revealed.

Research findings on the fundamental combustion mechanisms of NH3

The flame velocity of NH3 is only about one fifth that of methane (CH4), the flame temperature is lower, and a narrower combustible range is exhibited. Therefore, maintaining a stable flame is an issue for using NH3 as a fuel. In addition, there is a concern that a large amount of “fuel NOX” produced from nitrogen atoms in the fuel would be generated when NH3 is used as a fuel. (In the case of the combustion of CH4, “thermal NOX” is produced from N2 in the air.)

These fundamental issues related to the NH3 combustion mechanism were explored in detail for the first time by a Tohoku University research team led by Dr. Hideaki Kobayashi. The research findings elucidated a scientific understanding of NH3 combustion [1] and helped devise designs and solutions to problems that had arisen in the course of development of NH3 combustion equipment.

The problem of NH3 combustion stability was solved by using a swirl burner [2] to mix the gases inside the combustor. It was also found that the formation of NOX could be contained by burning NH3 in the combustor under the condition in which a slight surplus of NH3 was present in the combustion gas. Under this condition, NOX that happened to be produced in the combustion was converted to N2, with the surplus NH3 acting as a reductant. In other words, NH3 worked both as fuel and reductant in NH3 combustion. This reduction effect is not surprising, given that NH3 is used as a reductant in exhaust gas denitration systems in thermal power plants and diesel trucks. It was also found that these effects were enhanced under high pressure combustion. This is advantageous for the containment of NOX emissions in larger gas turbines that burn fuel at higher pressures.

Since the conditions for NOX emission containment were identified, a new combustion method called “rich-lean two-stage combustion [3]” was developed [4] to make further reduction of NOX emissions possible.

These research results on the combustion mechanism of NH3 were the basis for work supported by the SIP “Energy Carriers” initiative on combustion technologies including gas turbines, coal-NH3 co-firing boilers, and industrial furnaces.

Small gas turbines

In the field of small gas turbines, Toyota Energy Solutions Corp. developed 50 and 300kW-class 100% NH3-fired micro gas turbines. This development was carried out in close cooperation with the group at Tohoku University and combustion technology researchers at the National Institute of Advanced Industrial Science and Technology (AIST).

At AIST, a power generation test was conducted at the Fukushima Renewable Energy Institute (FREA) using a 50 kW micro gas turbine generator. The tests proceeded first with kerosene/NH3 co-firing, then with CH4/NH3 co-firing, and finally with 100% NH3 firing. It was confirmed that the gas turbine could generate electricity stably at the expected efficiency rate even during 100% NH3 firing, and that NOX emissions were reduced to a level that could be removed by conventional denitration equipment [5]. Based on these results, Toyota Energy Solutions has developed a 300 kW class 100% NH3-fired micro gas turbine generator.

Medium-size gas turbine for power generation

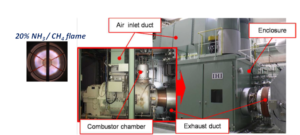

IHI Corporation’s contribution to the SIP “Energy Carriers” work involved development of a low-NOX combustor for the co-firing of CH4/NH3 in a medium-sized power generation turbine. The company was able to show that a 2 MW-class gas turbine could generate power by co-firing CH4 and NH3 [6] with a co-firing rate [7] of 20%. The demonstration verified that NH3 co-firing would reduce CO2 emissions in proportion with the co-firing rate; that NOX emissions could be controlled below the environmental standard using conventional denitration equipment; and that essentially all of the NH3 fuel would be combusted [8].

Large gas turbines for power generation

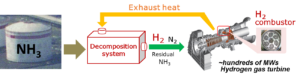

For large gas turbines of several hundred megawatts, Mitsubishi Heavy Industries Engineering Corporation (MHI) and Mitsubishi-Hitachi Power Systems, Inc. (MHPS) worked on the develoment of a fuel supply system that used NH3 as a hydrogen carrier to supply hydrogen to a CH4/H2 co-fired gas turbine which had already been developed by MHPS in a separate R&D project [9]. The reason MHI/MHPS did not use NH3 directly as a fuel is that operating temperatures tend to go up with an increase in combustor size, and higher temperatures tend to produce higher levels of NOX.

The MHI/MHPS fuel supply system involved decomposition of NH3 using the gas turbine’s waste heat and a catalyst to produce hydrogen. Here a key development target was the optimal distribution of waste heat from the gas turbine to the NH3 decomposer without sacrificing the overall energy efficiency of the generation process. Another technological challenge was the development of a NH3 decomposition system that can operate efficiently and stably. Detailed design studies supported by the SIP “Energy Carriers” initiative found that there may even be a possibility of increasing overall power generation efficiency beyond that of a natural gas (CH4)-fired combined cycle gas turbine power generation system [10].

Development of this technology was continued after the end of the SIP “Energy Carriers” initiative with financial support from the New Energy and Industrial Technology Development Organization (NEDO).

Postscript

Mr. Shiozawa advises readers who would like more detailed information to refer to the November 2019 edition of the Journal of the Combustion Society of Japan which features “Initiatives for Social Implementation of Ammonia Direct Combustion” [11]. In this special issue, the researchers who actually carried out the work supported by the SIP “Energy Carriers” initiative describe their findings and achievements for each of their R&D focuses. The SIP “Energy Carriers” work also attracted the attention of the Combustion Institute [12], an international academic society of combustion science. The Combustion Society of Japan, the Combustion Institute’s Japanese branch, in addition to publishing the special issue, awarded its 2019 Technology Award to the SIP “Energy Carriers” initiative for supporting valuable research on NH3 combustion. Finally, the SIP “Energy Carriers” initiative produced a 10-minute English-language video that describes the initiative’s R&D achievements.

References

[1] The Combustion Institute invited Professor Hideaki Kobayashi to its International Symposium held in Dublin in 2018 to speak on the topic of NH3 combustion technology. His presentation was published as a paper entitled “Science and technology of ammonia combustion,” (Proceedings of the Combustion Institute 37(1) p. 109 (November 2019)).

[2] A swirl burner uses a set of guiding vanes to give a swirling motion to the combustion air.

[3] A combustion method in which NH3 and H2 generated by the decomposition of NH3 are combusted in a slightly NH3-rich condition in the primary combustion zone, followed by the dilution of the combusted gas with air in the secondary combustion zone.

[4] “Significance and Impact of Ammonia Combustion Research,” Hideaki Kobayashi, Akihiro Hayakawa, Vol. 61, No. 198, pp. 277-282, Journal of the Combustion Society of Japan, November 2019.

[5] “Demonstration of Ammonia Fuel with Small Gas Turbines,” Norihiko Iki, Journal of the Combustion Society of Japan, Vol. 61, No. 198, pp. 283-288, November 2019.

[6] http://www.ihi.co.jo/all_news/2018/technology/2019-4-18/index.html

[7] In terms of heat value. All co-firing rates described in this article are presented on this basis.

[8] “Demonstration Test of Ammonia/Natural Gas Co-Firing Power Generation with 2MW class Gas Turbine,” Shintaro Ito, Masahiro Uchida, Toshiyuki Suda and Toshiro Fujimori, Journal of the Combustion Society of Japan, Vol. 61, No. 198, pp. 289-292, November 2019.

[9] https://www.mhps.com/jp/news/20190119.html

[10] “Development of Ammonia Utilization Technology for Large Gas Turbines for Power Generation,” Masakazu Nose, Hidefumi Araki, Noriaki Senba, Hiroyuki Furuuchi and Satoshi Tanimura, Journal of the Combustion Society of Japan, Vol. 61, No. 198, pp. 291-298, November 2019.

[11] 日本燃焼学会誌, Journal of the Combustion Society of Japan, Vol. 61, No. 198, pp. 277-330, November 2019.

[12] An international, non-profit, educational and scientific society on combustion science and technology founded in 1954 and headquartered in Pittsburgh, Pennsylvania.