NH3 Fuel Conference 2017

November 1, 2017 November 2, 2017 Minneapolis United States

1 – 2 November

Schedule

NH3 Energy Overview and Safety

Wednesday, November 1, 2017 8:00 am 10:30 am

Presentation

NH3: The Optimal Alternative Fuel (2017)

Unlike some technology areas where “all of the above” has significant advantages, there are tremendous advantages associated with choosing a single, optimized, liquid transportation fuel. The cost, efficiency and environmental benefits associated with choosing an optimized liquid transportation fuel are enormous and merit serious consideration. NH3 most closely meets the criteria for an ideal liquid transportation fuel. It is the most efficient and cost-effective means of delivering hydrogen and has an extensive world-wide delivery system already in place. Using currently available catalytic controls, NH3 emissions can be even cleaner than hydrogen engine emissions. While NH3 can effectively be produced using…

Presentation

Dutch Initiatives to Store Sustainable Energy in the Form of Ammonia

Proton Ventures BV is a company dedicated to supply mini ammonia units for storing decentralised produced (sustainable) energy. Proton has developed a commercial unit for the production of small amounts of ammonia, which can store up to 25 MW of power or equivalent (bio-) gas energy. Hans Vrijenhoef, as the director of the company, will give an overview of existing plans in The Netherlands to store this decentralised energy and to make use of this in an economic way. The N-Fuel units will be skid-mounted, safe in operation, and almost fully automated in order to keep CAPEX and OPEX costs…

Presentation

Nitrogen-Based Fuels: Renewable Hydrogen Carriers

Renewable energy sources such as solar and wind suffer from an intermittent power output, making energy storage a key element in future energy infrastructure. Fuels offer both high energy densities and efficient transport compared to other energy storage alternatives. One energy storage solution is water electrolysis. However, the generated hydrogen is incompatible with the global fuel infrastructure, inhibiting its implementation as an energy vector. Storing hydrogen on carrier atoms provides a safe and convenient way to utilize and transport renewable energies. While carbon–based fuels are commonly suggested, using nitrogen as a hydrogen carrier can potentially offer a superior option. In…

Presentation

Ammonia Fuel Safety

This paper introduces the existing literature on the safety of using ammonia as a fuel, which provides comparative data for a range of traditional and alternative fuels and energy carriers. The studies reviewed conclude that risk levels associated with using ammonia as a fuel are “similar to those of gasoline,” or “similar, if not lower than for the other fuels,” also including hydrogen, methanol, LPG, and CNG. Ammonia as a fuel can meet all “acceptable” risk levels in even the most stringent regulatory jurisdictions. Addressing popular misconceptions and fears by providing robust sources for quantitative data on the dangers of…

Presentation

Ammonia Renewable Energy Fuel Systems at Continental Scale

We must soon “run the world on renewables” but cannot, and should not try to, accomplish this entirely with electricity transmission. New, abundant, low-cost, unconventional natural gas supplies are finite; burning adds CO2 to Earth’s atmosphere. Humanity’s goal must be nothing less than: Transforming the world’s largest industry from ~80% fossil to ~100% renewable, CO2-emission-free energy sources as quickly as we prudently and profitably can. We should now carefully consider using pipeline networks, rather than the electricity grid, for solving the three salient technical problems of renewable energy (RE) at lower cost: Transmission: from diverse, stranded, remote, rich RE resources…

Presentation

Comprehensive Evaluation of NH3 Production and Utilization Options for Clean Energy Applications

The project proposes a comprehensive investigation on the analysis, assessment and optimization of ammonia synthesis processes under renewable energy portfolio, including low-cost hydro, wind, solar, geothermal, ocean, biomass, etc. Furthermore, ammonia production via hydrocarbon decomposition, which will be investigated in the study, is a promising option to utilize fossil fuels in a cleaner and environmentally benign way. Case studies for various locations and applications in communities, cities and provinces to develop and implement clean solutions are performed. The objectives of this project include energy and exergy analyses, environmental impact assessments, thermo-economic analyses and evaluations, optimization studies, experimental investigation, scalability and…

Presentation

The Role of "Green" Ammonia in Decarbonising Energy Systems: Practical Demonstration and Economic Considerations

Ammonia has the potential to contribute significantly to the decarbonisation of energy systems, by offering a practical, carbon-free hydrogen storage and transportation vector as well as a green fuel in its own right. To better understand the prospects and challenges surrounding the use of ammonia in energy systems, Siemens is leading a collaborative project to build and test an ammonia-based energy storage system at the Rutherford Appleton Laboratory in the UK. Together with its project partners (the UK Science and Technology Facilities Council, the University of Oxford and the University of Cardiff), and supported by Innovate UK, Siemens will demonstrate…

NH3 Fuel End Use

Monday, November 1, 2021 12:30 pm 3:00 pm

Presentation

Combustion Emissions from NH3 Fuel Gas Turbine Power Generation Demonstrated

Osamu KurataNorihiko IkiTakahiro InoueTakayuki MatsunumaTaku TsujimuraHirohide FurutaniHideaki KobayashiAkihiro Hayakawa

To protect against global warming, a massive influx of renewable energy is expected. Although H2 is a renewable media, its storage and transportation in large quantity is difficult. NH3 fuel, however, is an H2 energy carrier and carbon-free fuel, and its storage and transportation technology is already established. Although NH3 fuel combustion was studied in the 1960s in the USA, the development of an NH3 fuel gas turbine had been abandoned because combustion efficiency was unacceptably low [1]. Recent demand for H2 energy carrier revives the usage of NH3 fuel, but no one has attempted an actual design setup for…

Presentation

Detailed Observation of Coal-Ammonia Co-Combustion Processes

Coal-fired power generation is supplying about 30% of the world’s primary energy. Almost all of coal-fired power plants in Japan employ the pulverized coal combustion method. In the pulverized coal combustion, coal is pulverized into a powder of several tens of microns. This method enables to burn coal effectively because of the large surface to volume ratio. Pulverized coal particles are supplied to the actual boilers with primary air whose Air/Coal ratio (mass flow rate of primary air/mass flow rate of pulverized coal) is set to 2.0. Co-combustion of coal with ammonia has been studied with the aim of reducing…

Presentation

Development of Materials and Systems for Ammonia-Fueled Solid Oxide Fuel Cells

Koichi EguchiYosuke TakahashiHayahide YamasakiHidehito KuboAkihiro OkabeTakenori IsomuraTakahiro Matsuo

Hydrogen is the primary fuel source for fuel cells. However, the low volume density and difficulty in storage and transportation are major obstacles for the practical utilization. On-site generation of hydrogen from its carrier is an effective method for the fuel supply. Among various hydrogen carriers, ammonia is one of the promising candidates. Ammonia has high hydrogen density. The boiling point of ammonia is relatively high, leading to the ease in liquefaction and transportation. Hydrogen can be produced from ammonia with a mildly endothermic process. The reaction temperature of ammonia cracking is about 600˚C or higher which is close to…

Presentation

Development of New Combustion Strategy for Internal Combustion Engine Fueled By Pure Ammonia

Ammonia is considered as a promising hydrogen-carrier with good storability and transportability, which, then, can be used as a carbon-free fuel as needed. However, once the ammonia is produced from the regenerative sources, it is essential to develop the energy conversion device of the chemical energy stored in ammonia into some other useful forms, e.g. electricity. Among various candidates, we focus on an internal combustion engine as energy conversion device which can be applied on automobile, power plant and etc. and can use ammonia as fuel only by simple modification. There have been many studies on the use of ammonia…

Presentation

Direct Ammonia Fuel Cell Utilizing an OH- Ion Conducting Membrane Electrolyte

We describe the techno-economic background and the R&D work scheduled for the ARPA-E project “Direct Ammonia Fuel Cells (DAFCs) for Transportation Applications,” which is about to start under the REFUEL program. The project is led by Shimshon Gottesfeld & Yushan Yan, University of Delaware, Jia Wang & Radoslav Adzic, Brookhaven National Laboratory, Chulsung Bae, Rensselaer Polytechnic Institute, and Bamdad Bahar, Xergy Inc. The multidisciplinary R&D work scheduled will cover the fields of advanced membrane and electrocatalyst development, MEA development and fabrication, and stack engineering. The latter two activities will be supported by work at POCellTech, with Miles Page as lead.…

Presentation

Effect of Water on the Auto-Ignition of a Non-Carbon Nitrogen-Based Monofuel

The fluctuating nature of renewable energy sources is becoming a limiting factor in their widespread utilization. Energy storage solutions must be developed to overcome this issue. Chemical fuels are considered to be a promising solution to this problem. We are studying the implementation of nitrogen-based fuels for this purpose. An aqueous solution of ammonium nitrate and ammonium hydroxide (AAN) is suggested as a carbon-free nitrogen-based synthetic monofuel. This solution may serve as a renewable nitrogen-based synthetic hydrogen carrier since it is safe to store, transport and utilize. Since ammonium hydroxide (AH) and ammonium nitrate (AN) act as reducer and net…

Presentation

Effects of the Thickness of the Burner Rim, the Velocities of Fuel and Air on Extinction Limit of Ammonia Coaxial Jet Diffusion Flame

Yohei IshikawaJun HayashiHiroyuki TakeishiTakahiro OkanamiKimio IinoFumiteru AkamatsuYasuyuki YamamotoYoshiyuki Hagiwara

Ammonia is regarded as one of the alternative fuels because CO2 doesn’t emit during the combustion process of ammonia. Ammonia also has advantages in storage and transportation. In addition, ammonia has a potential to be a “hydrogen carrier” because of high amount of hydrogen content. However, there are several combustion related problems such as the low flammability, the low radiative power and the high NOx formation. To use ammonia as a fuel, therefore, it is necessary to understand the fundamental phenomena of the combustibility of the ammonia such as laminar burning velocity, strength of the radiation and extinction limit. Since…

Presentation

Efficient and Clean Combustion of Ammonia-Hydrogen-Air Mixtures

Based on its well-known merits ammonia has been gaining special attention as a potential renewable energy carrier which can be replaced in power generation systems. Considering its low flame speed and its potential for producing fuel NOx as the main challenges of combusting ammonia, flame stability, combustion efficiency, and NOx formation are experimentally investigated. Focus is on premixed ammonia-hydrogen-air flames with high mixture fractions of ammonia (60-90% by volume) under standard temperature and pressure conditions. We introduce silicon-carbide (SiC) porous block as a practical and effective medium for ammonia-hydrogen-air flame stabilization which enables stable and efficient combustion of the mixtures…

NH3 Fuel End Use and Synthesis

Wednesday, November 1, 2017 3:15 pm 5:45 pm

Presentation

Methods for Low NOx Combustion in Ammonia / Natural Gas Dual Fuel Gas Turbine Combustor

Ammonia is a carbon-free fuel, so it has potential to reduce carbon dioxide emission from power plants when used as a fuel. However, combustion characteristics of ammonia are notably different from hydrocarbon fuels, especially regarding NOx emission [1]. The nitrogen atom of the ammonia molecule may cause high NOx emission. Therefore, special techniques to reduce NOx emission are essential for gas turbine combustors which burn ammonia and natural gas. The results of our previous study [2] showed the characteristics of NOx emission in single-stage combustion. In this study, the concept for low-emission combustion in two-stage combustion has been examined numerically…

Presentation

NH3 / N2 / O2 Non-Premixed Flame in a 10 kW Experimental Furnace – Characteristics of Radiative Heat Transfer

Ryuichi MuraiRyohei OmoriRyuki KanoYuji TadaHidetaka HigashinoNoriaki NakatsukaJun HayashiFumiteru AkamatsuKimio IinoYasuyuki YamamotoYoshiyuki Hagiwara

There are severe issues on increasing amount of carbon dioxide (CO2) emission in the world. Many studies are devoted on alternative fuels. One of superior candidates is the utilization of hydrogen energy which can realize a low-carbon and hydrogen-based society. Ammonia might play an important role which is zero emission of CO2, and is useful for hydrogen energy carrier as a clean energy. Additionally, ammonia is an easily-liquefiable fuel with pressure of about 0.86 MPa and temperature of 293 K. Commercially, ammonia is produced in large quantity by the Haber–Bosch process. It is also to be produced by using catalyst…

Presentation

Delivering Clean Hydrogen Fuel from Ammonia Using Metal Membranes

The use of ammonia (NH3) as a hydrogen vector can potentially enable renewable energy export from Australia to markets in Asia and Europe. With a higher hydrogen density than liquid H2, plus existing production and transport infrastructure, and well-developed safety practices and standards, the financial and regulatory barriers to this industry are lower than for liquid H2 transport. The only significant technical barrier which remains, however, is the efficient utilisation of ammonia fuel at or near the point of use, either directly or through the production of H2. For H2 production from NH3, the purity of the product H2 is…

Presentation

Novel Catalysts for Ammonia Cracking and Synthesis

The most effective ammonia cracking catalysts are currently based on rare metals such as ruthenium and cobalt. While iron can efficiently crack ammonia at 600 °C, it is desirable to develop similarly inexpensive catalysts that are effective at lower temperatures between 350 °C and 500 °C. In this presentation, a new family of imide-based catalysts are described that crack ammonia around 400 °C to 550 °C. These materials do not behave as conventional surface-based catalysts and offer an affordable route for on-board cracking of ammonia for hydrogen fuel-cell cars. The operational parameters of a small 50W lab-based demonstrator will be…

Presentation

Future of Ammonia Production: Improvement of Haber-Bosch Process or Electrochemical Synthesis?

Ammonia, the second most produced chemical in the world (176 million tons in 2014), is manufactured at large plants (1,000 – 1,500 t/day) using Haber-Bosch process developed more than hundred years ago. A simple reaction of nitrogen and hydrogen (produced by steam methane reforming or coal gasification) consumes about 2% of world energy, in part due to the use of high pressure and temperature. With the global transition from fossil fuels to intermittent renewable energy sources there is a need for long term storage and long range transmission of energy, for which ammonia is perfect fit. To make it practical,…

Presentation

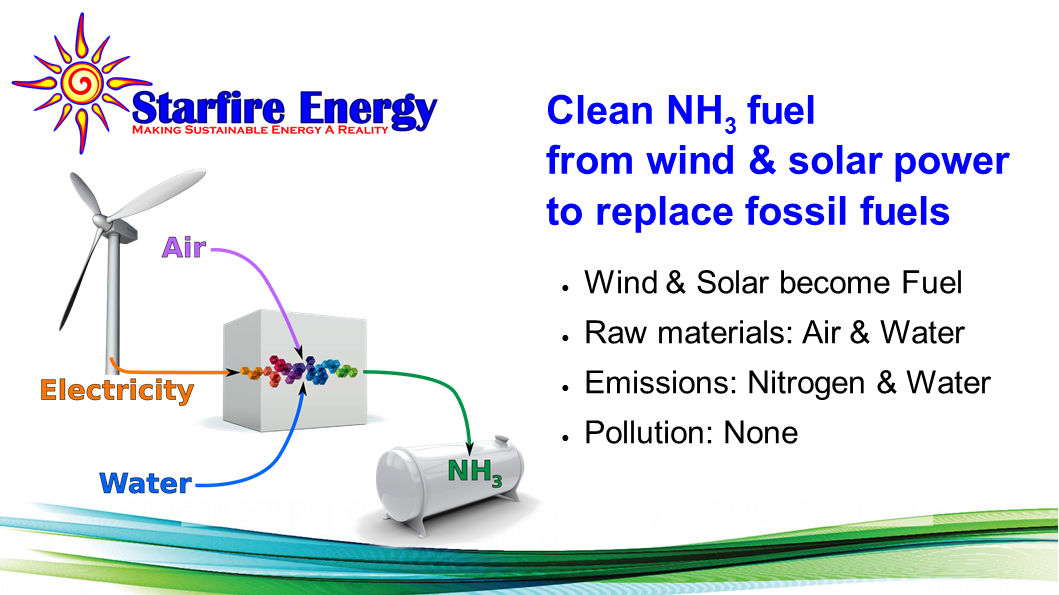

Fast-Ramping Reactor for CO2-Free NH3 Synthesis

Starfire Energy is developing a fast-ramping reactor for making CO2-free NH3 for fuel, energy storage, and agricultural applications. A fast-ramping reactor is desired to follow (a) variable electricity generation from CO2-free sources such wind and solar power plants or (b) variable availability from CO2-free baseload electricity generation such as nuclear or hydroelectric power plants. The reactor builds upon the Haber-Bosch process by (a) introducing a higher activity supported Ru catalyst (over 4.5 mmol g-1 h-1 at 1 atm and over 45 mmol g-1 h-1 at 10 atm) and (b) further enhancing the catalysis by applying an electric potential or electric…

Presentation

Lower Pressure Ammonia Synthesis

Ammonia is a very important chemical, mainly produced through the Haber-Bosch process. This process requires high temperature (>400 °C) and pressure (>150 bar) in order to ensure fast kinetics and high conversions, respectively.1 As a result, ammonia synthesis is known to be very complex and energy-intensive.2 To alleviate the complexity and energy requirements of ammonia synthesis, and to reduce the CO2 emissions, we are proposing an innovative reaction-absorption process to synthesize carbon-free ammonia in small plants.3 This green ammonia can be synthesized in wind-powered plants, with hydrogen from electrolysis of water and nitrogen from pressure swing adsorption of air.4 In…

Presentation

Nitrogenase Inspired Peptide-Functionalized Catalyst for Efficient, Emission-Free Ammonia Production

Ammonia-based fertilizers have enabled increases in food production to sustain the world’s population. Currently the major source of ammonia is the Haber-Bosch process, which requires high temperature and pressure and has low conversion efficiency, such that very large plants are required for economical production. Ammonia is therefore one of the most energy and carbon intensive chemical processes worldwide, largely due to the steam methane reforming step to produce the required hydrogen. Because of the very large plant scale and resulting centralization of production, ammonia may also be transported long distances to point of use, adding additional energy and emissions. Distributed,…

NH3 Synthesis I

Thursday, November 2, 2017 8:00 am 10:30 am

Presentation

Atmospheric-Pressure Synthesis of Ammonia Using Non-Thermal Plasma with the Assistance of Ru-Based Multifunctional Catalyst

Ammonia has much more uses than being a fertilizer. Its emerging applications include hydrogen carrier, fuel cells, clean transportation fuels, and other off-grid power applications. The traditional Haber Bosch process used to synthesize ammonia must be achieved at high temperature and pressure. The non-thermal plasma (NTP) allows for the synthesis of ammonia at a lower temperature and pressure conditions. It is proposed that the moderate process conditions can potentially allow a more economical construction and operation of ammonia production systems on distributed farms and renewable hydrogen production sites. In this study, we report the NTP synthesis of ammonia using dielectric…

Presentation

Coupling Integral Molten Salt Reactor Technology into Hybrid Nuclear: Direct Ammonia Production via H2 High Temperature Steam Electrolysis

Demands for safe, secure supplies of potable water across the planet are increasing faster than can be provided by natural, ever-depleting sources of fresh water. At the same time, world demand for electric power is also accelerating. Making H2 from Natural Gas is not an optimal or very efficient process that is also un-economic at higher and erratic gas costs. An Integral Molten Salt Reactor (IMSR) is uniquely suited to provide the very high temperatures (600 °C+ working temps) that are needed to generate both significant amounts of High Temperature Steam Electrolysis (HTSE)-derived Hydrogen & Oxygen (a feed for industrial…

Presentation

Design of Iron-Nickel Nanocatalysts for Low-Temperature Electrochemical Ammonia Generation

Lauren F. GreenleeShelby FosterPrashant AcharyaDavid SuttmillerCharles LoneyJulie RennerWayne GellettKatherine Ayers

The Haber-Bosch industrial process for ammonia production is the cornerstone of modern commercial-fertilizer-based agriculture. Haber-Bosch ammonia fueled the global population growth of the 20th century, and approximately half of the nitrogen in human bodies today originates from ammonia-based fertilizer produced by the Haber-Bosch process. However, the Haber-Bosch process operates at high temperature and high pressure to achieve high conversion efficiencies, and the hydrogen input comes from steam reforming of coal or natural gas. In addition to the energy costs, the large production of carbon dioxide as a greenhouse gas and the large required economies of scale motivate research efforts to…

Presentation

Early Transition Metal Carbide and Nitride Supported Catalysts for Ammonia Synthesis

More than 180 million tons of NH3 are produced annual via the Haber-Bosch process which converts N2 and H2 at high temperatures (400 – 500°C) and pressures (150 – 300 bars). Ammonia synthesis also accounts for 1-2% of global energy consumption.1 The development of higher activity catalysts that can operate under less severe conditions would enhance the economics associated with and sustainability of NH3 synthesis. Research described in this paper investigates the performance of transition metal carbide and nitride supported metals for NH3 synthesis. Previously, Mo2C and Mo2N have been reported to be more active than Ru-based catalysts, but slightly…

Presentation

Influence of H2 / N2 Ratio on Dynamic Behavior of Ammonia Production on Ru Catalyst Under Low Pressure Condition

Recently deployment of renewable energy such as sunlight and wind power or deployment of process technologies for carbon dioxide capture and storage (CCS) is indispensable to reduce the CO2-emission. However, there are some issues to be solved in order to accelerate the mass deployment of renewable energy. Since amount of renewable energy quite changes unstably with time, which depends on weather and place, development of process systems technology is an issue for stable and effective utilization of electric power that is generated by fluctuating renewable energy. Those in national institute of National Institute of Advanced Industrial Science and Technology (AIST)…

Presentation

LiH Mediated Ammonia Synthesis Under Mild Condition

Having a hydrogen content of 17.6 wt% NH3 is an attractive hydrogen carrier. The key issue for NH3 synthesis and decomposition is the development of non-noble metal based, highly active and stable catalysts that can be operated under mild condition. With the understanding on the interaction of LiH and Li2NH with 3d metals or their nitrides, novel catalyst systems, i. e., LiH-3d transition metals for NH3 synthesis and Li2NH-3d transition metal for NH3 decomposition, that have activities surpassing the highly active Ru-based catalysts were developed. The unique chemistry among TM, Li, N and H creates a two-reactive center mediated pathway…

Presentation

Load Range Enhancement of Haber-Bosch Process Designs for NH3 Sustainable Energy Storage By Multi-Parametric Optimization

With the world’s major shift towards renewable energy, the need of chemicals-based energy storage has drastically increased, as renewable energy is intermittent and energy storage medium is required. Among several chemical energy storage options, ammonia is promising for renewable energy on utility-scale. The Haber-Bosch ammonia synthesis was the first heterogeneous catalytic system employed in the chemical industry and developed over a period of century. However, the conventional ammonia process has been designed and optimized for steady state operation and high capacity. Power-to-ammonia requires a more flexible operation, small size reactors and decentralized production. The impact of adjustable parameters, such as,…

NH3 Synthesis II

Thursday, November 2, 2017 12:30 pm 3:00 pm

Presentation

Design Optimization of a Distributed Ammonia Generation System

Distributed ammonia generation located near farms is a promising alternative to the current practice of large-scale, centralized production. This production mode would reduce the need for transportation of ammonia over long distances currently caused by the mismatch between production and consumption locations. In addition, a small-scale ammonia synthesis process could more easily take advantage of distributed power generation based on wind or sunlight to reduce energy costs and lessen the dependence on fossil fuels. Distributed, renewables-based fertilizer production would largely insulate farmers against market uncertainty while also increasing the sustainability of the agricultural supply chain. However, a technically proven, economically…

Presentation

Exploring Peptide-Bound Catalysts for Electrochemical Ammonia Generation

Charles LoneyAshley GraybillCheyan XuJulie RennerPrashant AcharyaDavid SuttmillerLauren F. GreenleeLuke WilesKatherine AyersWayne Gellett

Today, most ammonia (NH3) manufacturing occurs via the Haber-Bosch process. This process consumes hydrogen from fossil fuels, and as a result NH3 contributes the highest amount of greenhouse gas emissions out of the top 18 large-volume chemicals made globally. Because the process is high temperature (400°–500°C) and pressure (150–300 atm) with a low (15%) single-pass conversion efficiency, the plants have to be very large to be economical. This means that ammonia is shipped from centralized locations, further increasing greenhouse gas emissions because of the fuel consumed in transportation. Additionally, their large size makes it difficult to integrate with renewable sources…

Presentation

Nitride-Based Step Catalysis for Ammonia Synthesis at Atmospheric Pressure

Formation of metal nitrides to activate dinitrogen is one avenue to ammonia and other nitrogen compounds. Attractive aspects are operation at atmospheric pressure and moderate temperatures, formation of stable chemical intermediates rather than reliance on somewhat sensitive heterogeneous catalysis, and inexpensive materials. If a single metal is used, however, one encounters tradeoffs somewhat akin to the well-known tradeoffs for Haber-Bosch catalysts. Results will be presented for metal nitride-based ammonia synthesis, and new metal alloys that can address some of the tradeoffs between affinity for nitrogen, and formation of ammonia when hydrogen is added. Options using water instead of hydrogen will…

Presentation

Dense Metallic Membrane Reactor Synthesis of Ammonia at Moderate Conditions and Low Cost

Commercial ammonia synthesis relies on the Haber–Bosch process that has remained largely unchanged for a hundred years. The equilibrium constant of this exothermic reaction quickly becomes unfavorable above 200 °C, but the catalyst requires temperatures above 400 °C to have sufficient activity. To overcome these conflicting requirements the process is conducted at extremely high pressure (100 – 200 atm) using multiple passes with inter-stage cooling to achieve sufficient conversion. A cost analysis reveals the compressors needed to reach the required pressures consist of 50% the capital cost for Haber-Bosch. Therefore, a longstanding scientific challenge has been to achieve NH3 synthesis…

Presentation

Our Iowa Renewable Hydrogen and Ammonia Generation System

The presentation will summarize the development of the demonstration size renewable fuel and fertilizer system on my Iowa farm. Solar power, water, and air are used to make hydrogen and ammonia fuel used to power a modified John Deere 7810 tractor. The ammonia can also be used to fertilize corn cropland. The development of the ammonia reactor will be described and its performance discussed. There are no carbon emissions in either the generation or consumption of the hydrogen and ammonia.

Presentation

Process Synthesis and Global Optimization of Novel Ammonia Production Processes

Synthetic ammonia production has played a huge role in sustaining population growth by providing the nitrogen in fertilizers that are widely used in modern agriculture. Even long after it was first commercially developed by Fritz Haber and Carl Bosch in the 1930s, the Haber-Bosch process remains the basis for industrial ammonia production today. Through reducing energy requirements by half in the last 50 years, centralized industrial plants have kept their technical and economic advantage over other modes of operation. However, the centralized production also comes with high transportation costs, since plant capacities usually exceed local ammonia consumption [1]. This and…

Presentation

Screening Binary Redox Pairs for Solar Thermochemical Ammonia Synthesis Using Machine Learned Predictions of Gibbs Formation Energies at Finite Temperatures

Solar thermochemical ammonia synthesis (STAS) is a reduction/oxidation (redox) cycle which enables the production of ammonia (NH3) from air, water, and concentrated sunlight. In this process, a metal nitride (MN) is oxidized by steam to produce a metal oxide (MO) and NH3; the resulting MO is reduced at high temperature (driven by concentrated solar radiation) and subsequently used to reduce atmospheric nitrogen (N2) and reform the MN and restart the NH3 synthesis cycle. The identification of optimal redox pairs (MO/MN) for this process has been historically limited by the lack of thermochemical data (i.e., Gibbs formation energies at finite temperatures)…

Presentation

Solid Oxide Cell Enabled Ammonia Synthesis and Ammonia Based Power Production

Haldor Topsøe’s leading role as supplier of ammonia synthesis catalysts and technology is well known. The company has, however, also been active for decades in developing Solid Oxide Cell based stacks and systems. The presentation will describe a novel, highly integrated process for ammonia synthesis based on Solid Oxide Electrolysis. The energy efficiency is very high due to ability of the SOEC to use steam generated from the synthesis reaction heat in the ammonia synthesis loop and the favorable thermodynamics of high temperature electrolysis. Experimental results from hydrogen generation from steam using SOEC and power production from ammonia using Solid…