Green ammonia demonstration plants now operational, in Oxford and Fukushima

By Trevor Brown on June 29, 2018

Two new pilot projects for producing “green ammonia” from renewable electricity are now up and running and successfully producing ammonia.

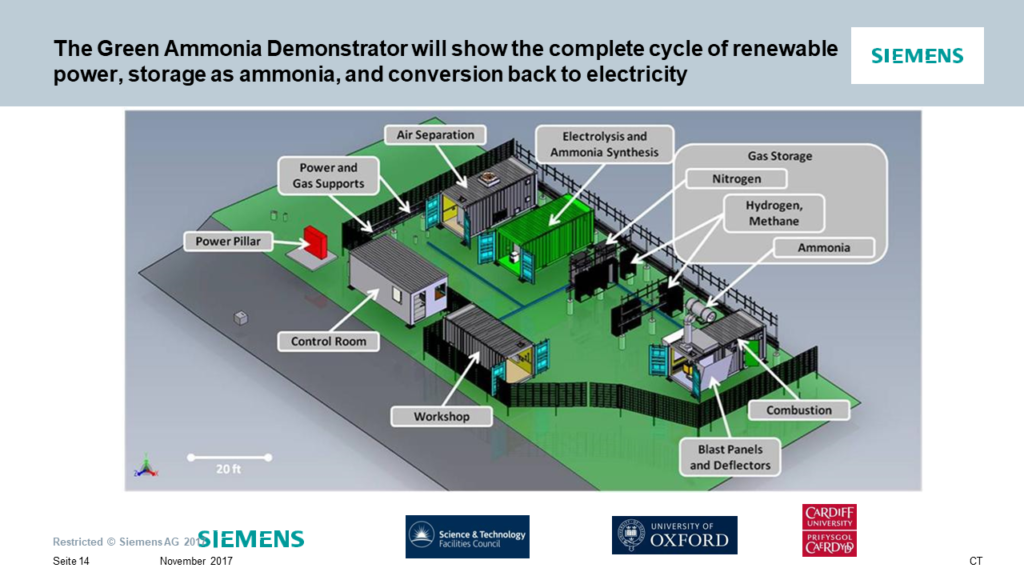

In April 2018, the Ammonia Manufacturing Pilot Plant for Renewable Energy started up at the Fukushima Renewable Energy Institute – AIST (FREA) in Japan. Earlier this week, Siemens launched operations at its Green Ammonia Demonstrator, at the Rutherford Appleton Laboratory outside Oxford in the UK.

The commercial product coming out of these plants is not ammonia, however, it is knowledge.

While both the FREA and Siemens plants are of similar scale, with respective ammonia capacities of 20 and 30 kg per day, they have very different objectives. At FREA, the pilot project supports catalyst development with the goal of enabling efficient low-pressure, low-temperature ammonia synthesis. At Siemens, the pilot will provide insights into the business case for ammonia as a market-flexible energy storage vector.

I’ve been fortunate to visit both projects over the last month, Siemens in May and FREA last week, and can attest that both sites are happy to host visitors wishing to tour their facilities.

Siemens — Green Ammonia demonstration plant

The Siemens launch attracted mainstream press coverage, including this from The Guardian:

The proof-of-concept facility at Harwell will turn electricity, water and air into ammonia without releasing carbon emissions. The ammonia is stored in a tank and later either burned to generate electricity, sold as a fuel for vehicles or for industrial purposes, such as refrigeration.

Dr Ian Wilkinson, programme manager for Siemens’ green ammonia demonstrator, said: “Storage is recognised as the enabler for intermittent renewable power.

“This is where we’re different from usual storage, we’re not just looking at power. Usually it’s [storage] just filling in the gaps when the sun’s not shining and the wind is not blowing. We’re looking at other uses, mobility and industrial uses.”

The Guardian, Siemens pilots the use of ammonia for green energy storage, 06/17/2018

Unfortunately, The Guardian didn’t fully understand these new markets for energy storage and ran with a simple but misleading story in which ammonia competes against batteries (“Firm hopes to better conventional batteries to store renewably generated power”).

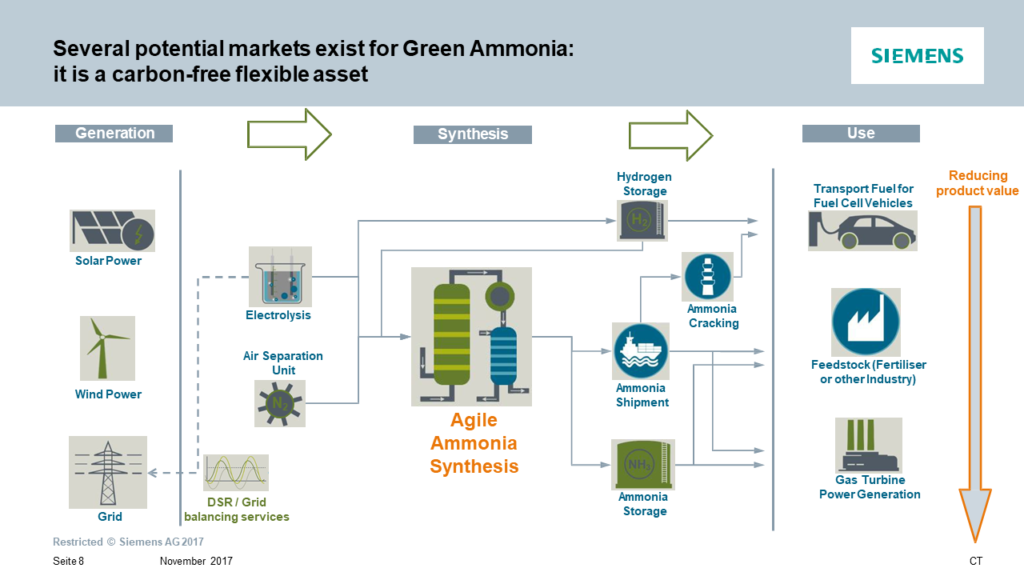

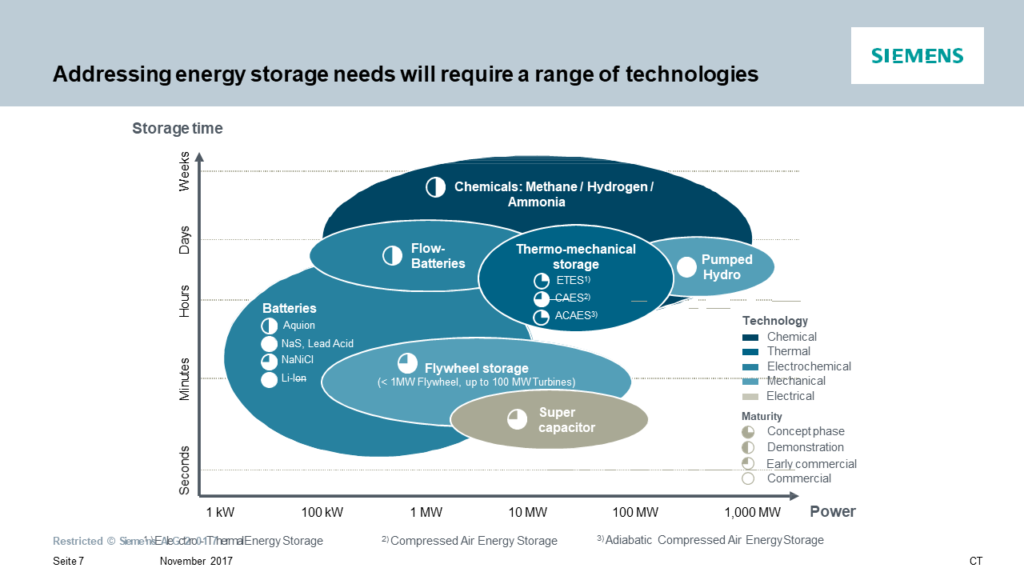

It is worth stressing that ammonia and batteries serve different energy storage markets. This is most clearly conveyed in a slide featured in many of Wilkinson’s presentations, most recently at the NH3 Fuel Conference in November 2017, which clearly distinguishes between batteries, which excel at short-term, small-scale storage, and chemicals like ammonia, which serve a completely different market: long-term and large-scale storage.

GreenTech Media provided a more accurate report:

“It’s pretty apparent that we will need a range of energy storage solutions to decarbonize our electricity generation,” Wilkinson added. “I think a lot of different storage technologies will be required.”

For short-term, low-capacity applications, it is likely that batteries would be the dominant storage technology, he said.

But where longer-duration, large-scale storage is needed, ammonia could play a role, particularly if the energy has to be transported from one place to another or stored in a location devoid of hills for pumped hydro or caves for compressed air.

“For big-capacity, long-duration storage, chemical fuels are hard to beat,” Wilkinson said. “Of course, we use chemical fuels a lot today, and they are ubiquitous for a reason. It’s just that all of our fuels right now are fossil-based.”

GreenTech Media, Siemens Tests Ammonia as a Form of Energy Storage for Renewables, 06/27/2018

Beyond electricity storage markets, however, once the renewable energy is stored in ammonia’s chemical bonds, it can be delivered to a range of markets. According to another of Wilkinson’s slides it is “a carbon-free flexible asset,” with potential to provide grid services like demand-side response (DSR) and long-term energy storage, but the flexibility to be sold into more conventional markets like nitrogen fertilizer, chemical feedstock, and, soon, carbon-free fuel.

As well as the synthesis system, the Siemens demonstrator includes not only storage assets but also combustion assets: an internal combustion engine adapted to generate electricity using ammonia as a fuel.

As Wilkinson explained to me in May, “It’s proof of principle, with the intention of demonstrating the full round trip of renewable power to ammonia and back to electricity.”

FREA – Ammonia Manufacturing Pilot Plant for Renewable Energy

FREA was established only recently, in April 2014, following the Great East Japan Earthquake. Unsurprisingly, little English-language publicity exists for its new ammonia production pilot plant, however, I wrote at length about this project, and its context within Japan’s SIP ‘Energy Carriers’ program, back in November 2016 (Low-carbon ammonia synthesis: Japan’s ‘Energy Carriers’ R&D).

While some of the other parts of the SIP project have changed since then, the ammonia pilot plant has quietly forged forwards. The pilot plant was built by JGC Corporation and its subsidiary JGC Catalysts and Chemicals, and is operating “to evaluate the performance of the developed catalysts and acquire the engineering data for scaling up in the future.”

The low-pressure and low-temperature conditions for the ammonia synthesis catalyst supports the efficient integration of electrolyzers into the process flow, allowing ammonia production to use hydrogen from electrolyzers running on renewable energy.

Both of these pilot plants will be featured in the 15th Annual NH3 Fuel Conference, in Pittsburgh, PA, on October 31, 2018, including initial results from operations. This year’s event will again be held as a Topical Conference as part of the broader AIChE Annual Meeting. The full conference schedule will be announced in July.

You can also read the full article at AmmoniaIndustry.com.