How to create a market for low-carbon ammonia: product labeling

By Trevor Brown on November 04, 2016

I wrote last week about ARPA-E’s “transformative” ammonia synthesis technologies, describing three technology pathways under development: low pressure Haber-Bosch, electrochemical processes, and advanced electrolysis.

ARPA-E’s ambitious R&D program might imply that a meaningful, commercial market for sustainable ammonia is still decades away. It represents, however, only the slow American tip of a fast-moving global iceberg.

In Japan, where there’s no debate about climate science, the national effort is already well underway, with three programs to develop low-carbon ammonia synthesis under the Cross-ministerial Strategic Innovation Promotion Program (SIP), ‘Energy Carriers.’

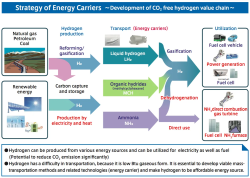

The broader aim of Japan’s ‘Energy Carriers’ program is to enable the transition of the national energy economy from a fossil fuel mix to a carbon-free hydrogen economy, using ammonia as a cost-efficient hydrogen carrier, among other options.

Of the ten programs within the ‘Energy Carriers’ initiative, each of the three that focus on low-carbon ammonia production seeks to improve one step in a single technological pathway.

First, the initiative aims to develop a high-temperature solar thermal energy supply; second, to produce hydrogen from the solar heat (either using a Membrane Iodine-Sulfur Process, or a new Steam Electrolysis system); and third, to develop a more efficient, low-temperature ammonia synthesis process using this CO2-free hydrogen.

Japan’s research schedule spans years, not decades. By 2018, they intend to be operating a pilot plant to demonstrate their “high-efficiency ammonia synthesis process from CO2-free hydrogen.” And the full portfolio of R&D from the ‘Energy Carrier’ program will be on display by 2020.

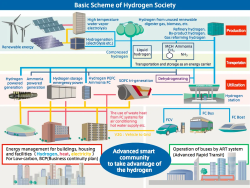

“I would like to demonstrate the hydrogen technologies developed for production, transportation, storage and utilization as tangible results at the Tokyo 2020 Olympic and Paralympic Games.”

Shigeru Muraki, Program Director, SIP Energy Carriers / Executive Adviser, Tokyo Gas Co.,Ltd

Japan’s SIP ‘Energy Carriers‘

The scale of ammonia’s energy opportunity dwarves the fertilizer industry. And, in terms of accelerating the expansion of global ammonia capacity, the speed of its deployment could make the Green Revolution seem slow and small by comparison.

For example, to meet its renewable energy targets for 2030, in just 13 years, Japan’s power generation sector could be importing 40 million tons of ammonia per year, which is about 20% of today’s total global production capacity.

The crucial point is that Japan is advertising itself as a potential customer for vast quantities of ammonia. And, as with any premium product, the nation’s power utilities would expect to pay a reasonable premium for the good stuff: the low-carbon ammonia.

Ken-ichi Aika, from Tokyo Institute of Technology, introduced the importance of product labelling in his presentation, CO2-Free NH3, at the recent NH3 Fuel Conference. His point was that the market mechanism that rewards investment in low-carbon ammonia production will only function when ammonia producers label their product, using a life-cycle analysis to determine its carbon footprint.

Because low-carbon NH3 performs, looks, and smells the same as high-carbon NH3, this is analogous to purchasing ‘expensive’ renewable electricity through the grid: the delivered electrons may not have been directly generated from wind or solar but the customer is paying for systemic decarbonization nonetheless. In the same way, the low-carbon ammonia customer might not actually receive low-carbon ammonia at the end of the pipeline, but the carbon-intensity of that delivered ammonia can be measured – and certified – and priced – all the way up the supply chain, from the low-carbon producer to the premium product purchaser.

(I note that it is also technically possible to determine the source – fossil or water – of the hydrogen contained in ammonia by molecular analysis. This is not strictly necessary, however, if a functioning mechanism for carbon accounting is in place throughout the supply chain. Nonetheless, it may prove to be a valuable method of verification.)

At the annual NH3 Fuel Conference, hosted by UCLA in September 2016 and featuring a keynote speech from an ARPA-E program manager, a large number of presentations from Japan made evident the speed and scale of development – and planned deployment – of ammonia fuel technologies. From novel synthesis processes, to efficient storage and power generation technologies, Japan’s national program is moving far quicker than the rest of the world realizes, with the help of major industry participants – such as IHI Corporation, Mitsui Chemical, and Toyota Industries, to name but a few.

With an energy density of 4.32KWh per liter, one metric ton of ammonia carries roughly 3MWh of energy. Think of a 30,000 metric ton ammonia tank as the equivalent of a 90GWh battery – one that won’t lose any power over time. To satisfy just 1% of Japan’s estimated 980TWh energy requirement in 2030, the nation would need to import 3 million metric tons of ammonia each year, almost three times its current production capacity. To meet its national target for 2030 of 13-14% energy from renewables through ammonia, Japan would need to purchase about 40 million tons, or 20% of today’s total global ammonia capacity.

That’s just one country, meeting a fraction of its requirements, less than fifteen years from today. Others will follow: some will deploy quickly, some slowly. Scale up these fractions for the rest of the world, and fertilizer will seem like a very secondary market.

No fertilizer producer currently bothers to ‘label’ its product to specify the carbon-intensity of the ammonia it sells, but they could all easily do so. Yara is the only producer that I know to have published real carbon footprint data, but even that only focuses on average numbers for ammonium nitrate across a continent of production units.

In North America, the obvious producers who could immediately begin marketing low-carbon ammonia include Koch Industries at Enid, OK, Dakota Gas at Beulah, ND, CVR Partners at Coffeyville, KS, and – starting next year – Agrium at Redwater, AB, because most of the CO2 produced at these plants is sequestered through CCS-EOR (note: I have deep reservations about the perceived net carbon balance of EOR).

Given a local market incentive, like a powerful nationwide retailer seeking to lower the carbon footprint of its supply chain, these plants could very soon be selling premium, green ammonia. How big this premium could be, only time, consumer demand, and a carbon tax will tell.

For Japan, sourcing such vast quantities of low-carbon ammonia is a bigger challenge.

In theory, any low-carbon ammonia producer willing to label its product, so that a carbon footprint can be determined and – crucially – priced, might soon welcome this new, better market for ammonia.

In practice, a number of Australian project developers are looking at their ammonia manufacturing base, are evaluating the short-term opportunities for CCS-EOR and long-term opportunities of vast untapped solar resources, and are reconsidering their long-standing trade relationship with Japan. As demonstrated by Keith Lovegrove of ITP Thermal in his NH3 Fuel Conference presentation, Japan – a future market for Australian solar ammonia, they’re reimagining Australia’s national identity as an exporter of natural resources.

Originally published at our sister website: How to create a market for low-carbon ammonia: product labeling at AmmoniaIndustry.com.