Ammonia Turbine Power Generation with Reduced NOx

By Trevor Brown on October 06, 2016

A common concern with ammonia fuel is that NOx emissions will be too high to control. However, in new research from Turkey, USA, and Japan, presented at this year’s NH3 Fuel Conference in September 2016, two things became clear.

First, NOx emissions can be reduced to less than 10ppm by employing good engineering design and exploiting the chemical properties of ammonia, which plays a dual role as both the fuel and the emissions-cleanup agent.

Second, the deployment of ammonia-fueled turbines for power generation is not only feasible, but actively being developed, with demonstration units running today and improved demonstration projects currently in development.

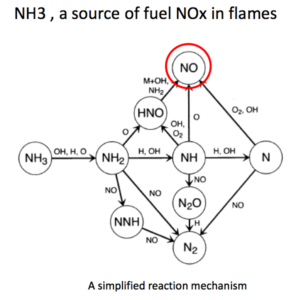

NOx emissions are not unique to ammonia fuel but are caused in all forms of air combustion, when atmospheric nitrogen and oxygen can react. NOx is the root of Volkswagen’s ‘clean diesel’ emissions cheating scandal.

(Nozari and Karabeyoglu)

NH3 Fuel Conference, 09/19/2016

Researchers from Koç University, in Turkey, and Space Propulsion Group Inc, in the USA, presented results from their examination of the chemical kinetics of NOx formation and investigation into the impact of various parameters on emissions levels. These parameters included the equivalence ratio, amount of ammonia in an ammonia-hydrogen-air mixture, and the combustion temperature.

In their conference presentation, NOx emission analysis and flame stabilization of ammonia-hydrogen-air premixed flames (Nozari and Karabeyoglu), they also investigated using a silicon carbide (SiC) porous block to increase flame stability. This further reduced emissions of NOx by increasing the heat conduction to the pre- and post-flame zones.

Similar investigations are underway in Japan, except these studies focus not on an ammonia-hydrogen fuel mix, but on an ammonia-methane dual fuel combustion.

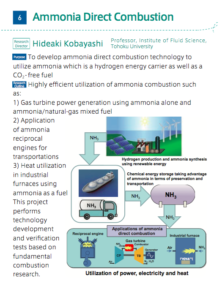

The Japanese program for “Ammonia Direct Combustion,” led by Research Director Hideaki Kobayashi at the Institute of Fluid Science, Tohoku University, is the sixth strand of a ten-part government initiative that aims to develop the full spectrum of hydrogen energy technologies, including ammonia as a hydrogen energy carrier.

This national research and development program was launched under the Cross-ministerial Strategic Innovation Promotion Program (SIP), “Energy Carriers.” The project to develop “Ammonia Direct Combustion” seeks to develop the “Highly efficient utilization of ammonia combustion” including:

- Gas turbine power generation using ammonia alone and ammonia/natural-gas mixed fuel

- Application of ammonia reciprocal engines for transportations

- Heat utilization in industrial furnaces using ammonia as a fuel

Three coordinated papers were presented by researchers from this project at the NH3 Fuel Conference, each reporting an area of progress under the Ammonia Direct Combustion area of the SIP Program, with a focus on turbine power generation. They were Combustion characteristics of ammonia/air flames for a model swirl burner and an actual gas turbine combustor (Hayakawa, et al), Power Generation and Flame Visualization of Micro Gas Turbine Firing Ammonia or Ammonia-Methane Mixture (Iki, et al), and Development of ammonia / natural gas dual fuel gas turbine combustor (Ito, et al).

It is worth highlighting a couple of important points from the many, highly technical results presented in these papers.

Ammonia can be used to reduce the high initial NOx emissions, which were 700ppm, down to less than 10ppm. The reduction reactions take place both within the turbine, in a selective non-catalytic reduction, and within an after-treatment unit, in a standard selective catalytic reduction (SCR) process. In the SCR, some of the ammonia fuel was directed to the exhaust gas; this clean-up process consumed about 2% of the total ammonia supplied to the system.

The remaining challenge, therefore, is not just to use ammonia to clean up its own emissions – this has now been demonstrated, achieving safe levels of NOx emissions – but to reduce NOx formation in the first place, within the combustion process. These presentations illustrated the challenge of achieving both low NOx and high combustion efficiency: within a single-stage combustor, this proved difficult. The next step in their research, therefore, is to develop and demonstrate the multi-stage combustor, “currently in development.”

The SIP project builds cooperation between government, academia, and corporations, led by the government. The corporate partners developing this ammonia power generation project include turbine manufacturer Toyota Industries and engineering / construction firm IHI Corporation.

For a full description of Japan’s SIP “Energy Carriers” program, see the full PDF.